Efficient multi-layer overlapping pouring device for casting parts

A casting, high-efficiency technology, applied in casting molding equipment, casting mold, casting mold composition, etc., can solve the problems of insufficient feeding pressure, waste of resources, inaccurate casting size, etc., to reduce production costs, improve casting quality, The effect of improving casting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

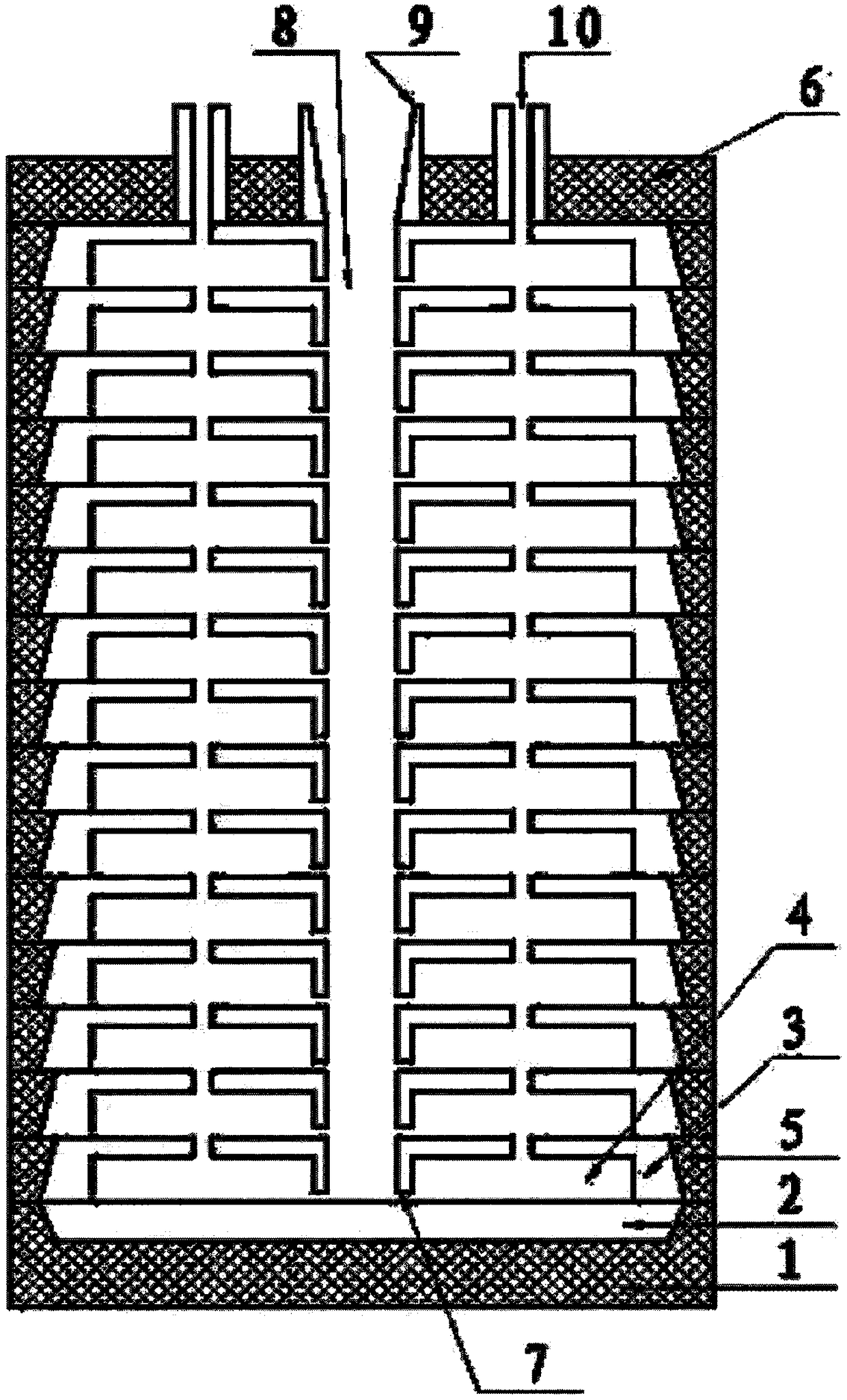

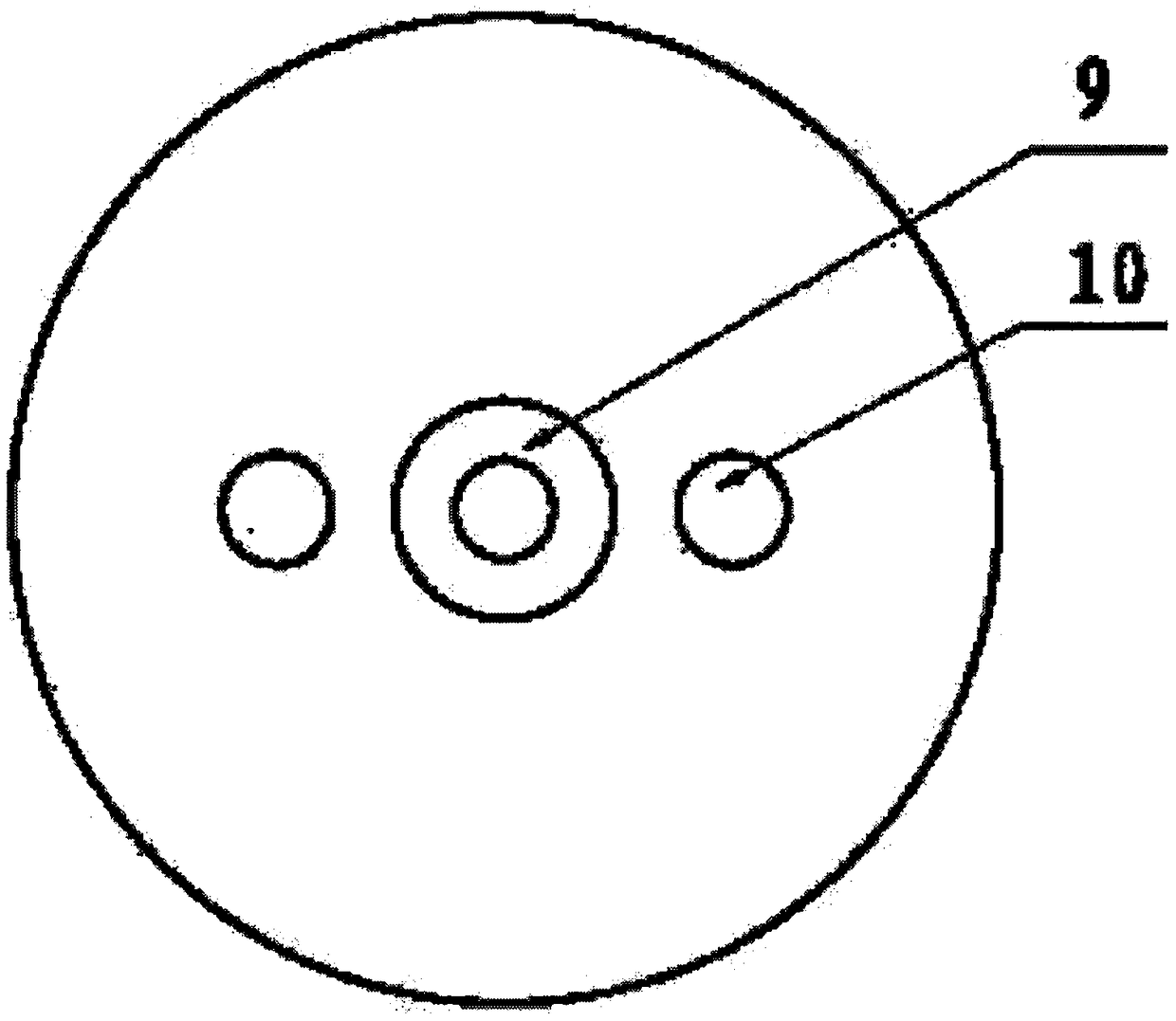

[0010] exist figure 1 with figure 2 Among them, there is a bottom sand mold 2 on the bottom plate 1, and a main sand mold 3, a ferrule 4, a casting 5 and a water inlet 7 are arranged on the top of the bottom sand mold 2, and the main sand mold 3, the ferrule 4, the casting 5 and the inlet The nozzle 7 forms a pouring single layer; the upper layer of the device has a cover plate 6, a pouring cup 9 and a connected runner 8, and there is an air outlet 10 between the cover plate 6 and the pouring cup 9; overlapping pouring is formed by superimposing the pouring single layers.

[0011] The technological process of implementing this device is:

[0012] 1. Mold making: Design mold making according to the size requirements of casting drawings. The mold is divided into bottom sand mold 2, main sand mold 3, and cover plate 6. The one-piece sprue 8, water inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com