Intelligent bolt monitoring system for fault detection of machine tool spindle transmission part

A technology of intelligent bolts and transmission components, which is applied in the direction of metal processing machinery parts, measuring/indicating equipment, metal processing equipment, etc., can solve problems such as the intelligent bolt monitoring system with vibration signals that have not yet been seen, and achieve convenient and effective multi-sensor network monitoring , avoid wiring problems, protect the effect of machine and personnel safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in further detail below in conjunction with accompanying drawing:

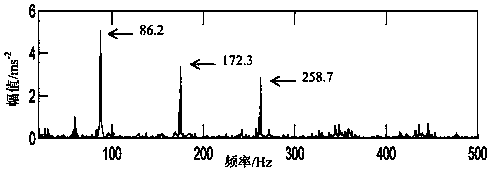

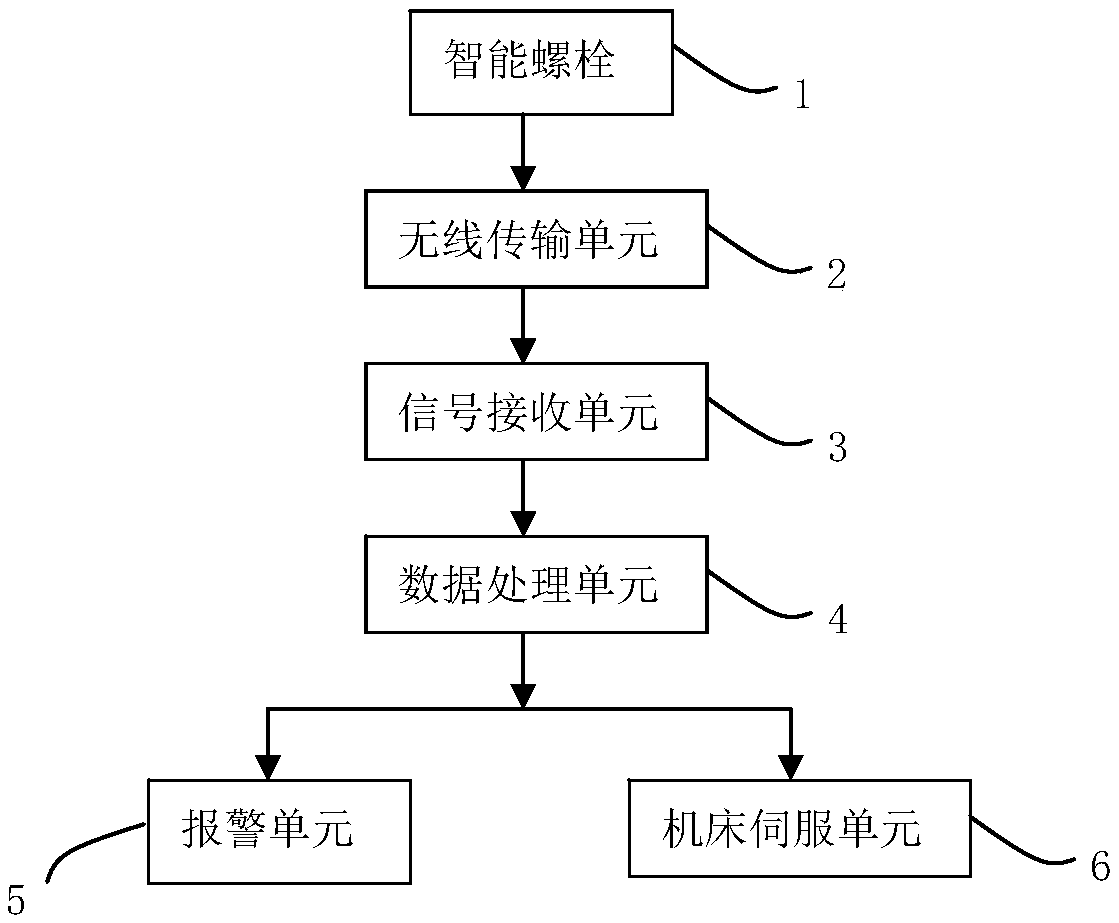

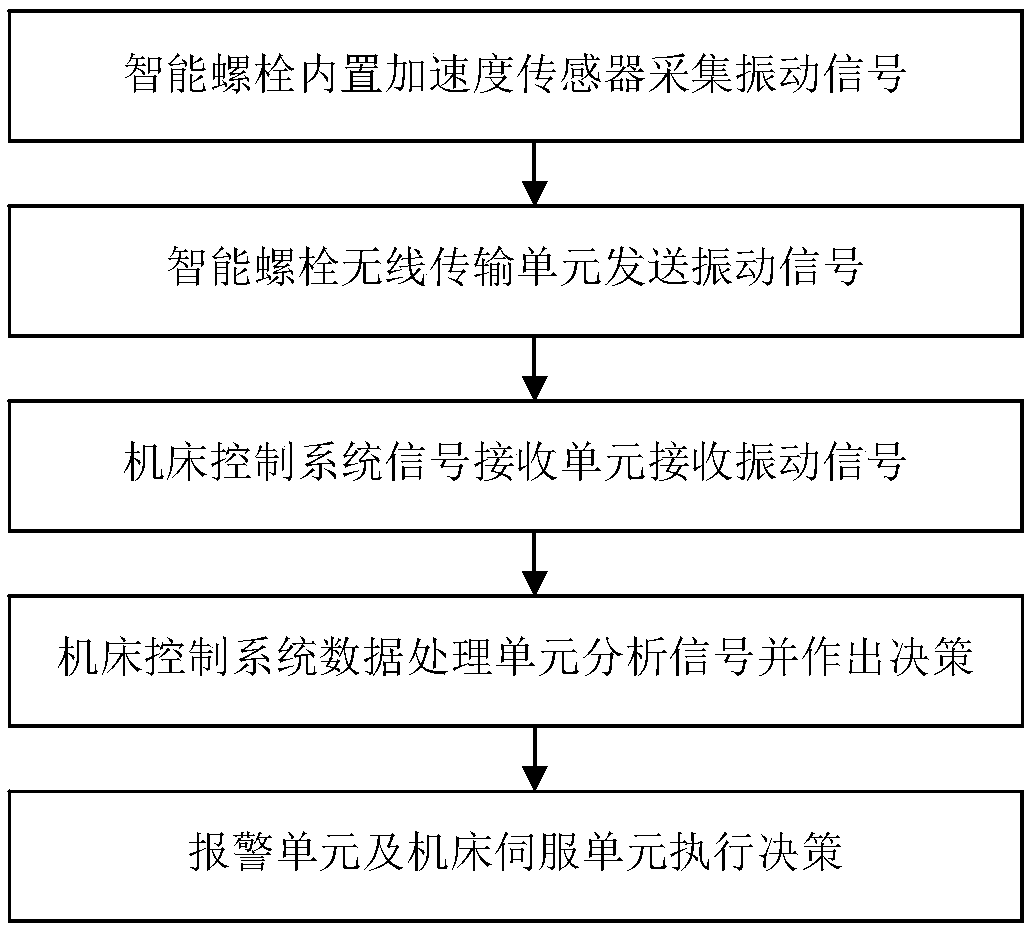

[0037] Aiming at the problem of automatic and continuous monitoring of machine tool running status, an intelligent bolt monitoring system for fault detection of machine tool spindle transmission parts is proposed. It monitors equipment status through bolts that can be seen everywhere on the machine tool. The combination of frequency matching and average amplitude monitoring is used to determine whether machine tool collision accidents or mechanical failures (such as spindles, bearings, gears, etc.) occur on the machine tool, and automatically make emergency shutdown, maintenance alarm or continue operation decisions.

[0038] Most of the connections between machine tool parts are realized by bolts. If the sensor is placed on a single part, because the quality and rigidity of a single casting or forging are relatively stable, the relatively weak vibration signal is not c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com