Prefabricated assembling cast-in-place joint ring beam mold

A prefabricated assembly and cast-in-place technology, which is applied in molds, manufacturing tools, mold fixtures, etc., can solve problems such as difficulty in ensuring the quality of ring beams, unsatisfactory effects, and reduced construction efficiency, so as to shorten the construction period and ensure construction quality , The effect of reducing cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention is described further below:

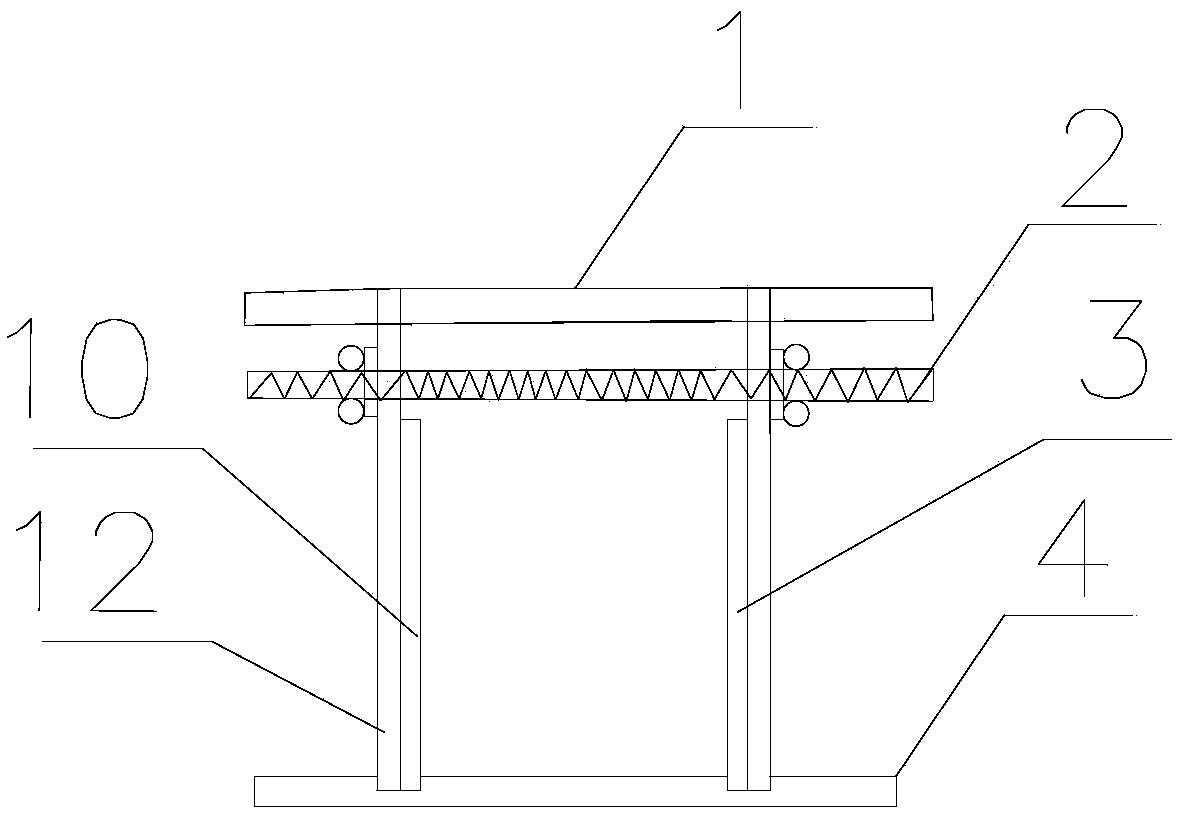

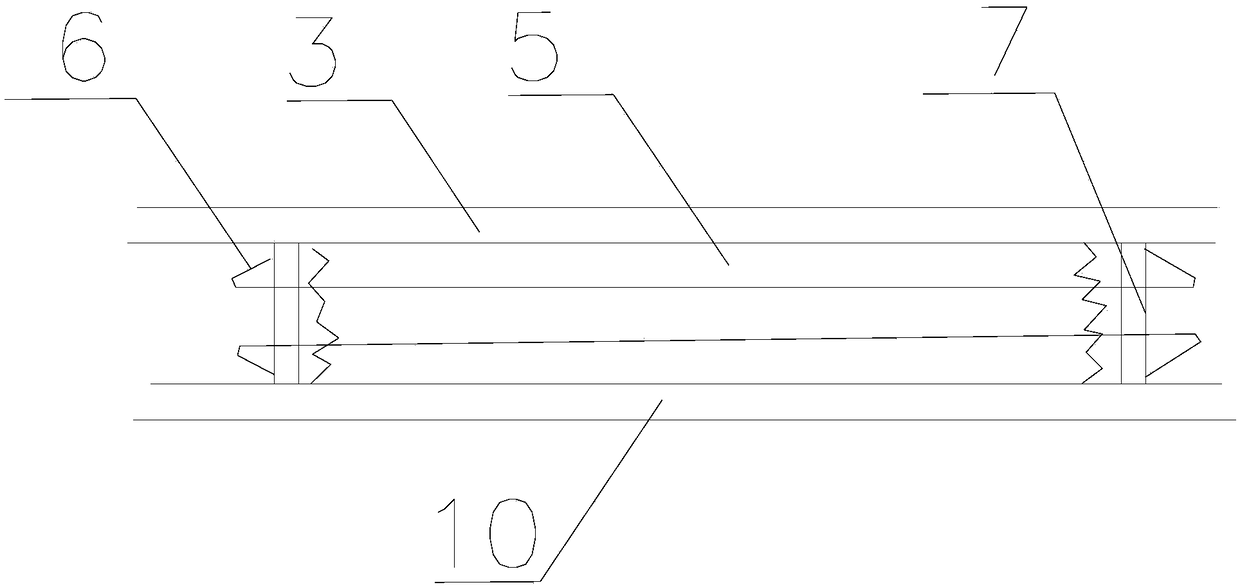

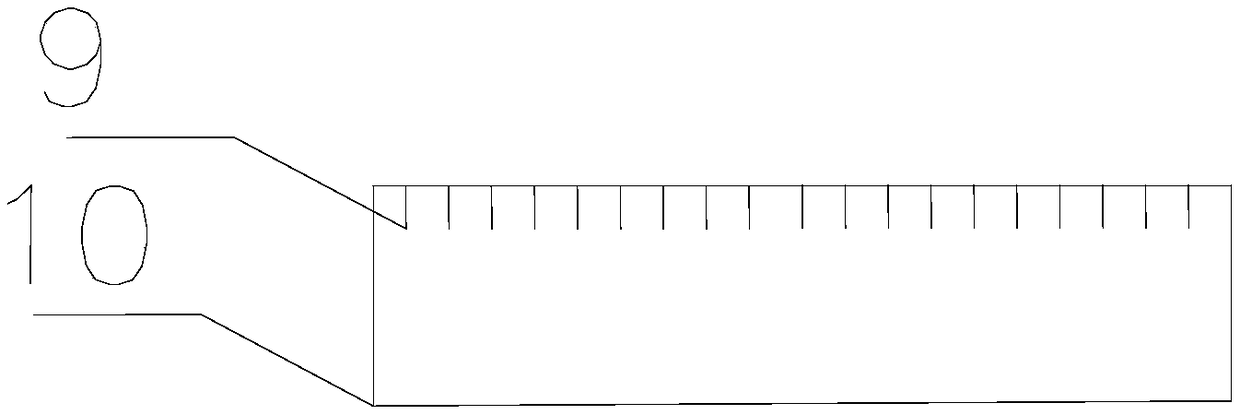

[0019] See Figure 1-Figure 3 , a prefabricated and assembled cast-in-place joint ring beam mold, including side formwork A10, side formwork B3, slide rail 1, lead screw 2, bottom formwork 4, inner formwork 7, wooden square 12, on the bottom formwork 4 there is Two vertical formwork grooves 11 arranged in parallel, the bottoms of side formwork A10 and side formwork B3 are respectively inserted in the formwork grooves 11 on the bottom template 4, and the wooden square 12 is arranged on the sides of side formwork A10 and side formwork B3. On the outside, slide rails 1 are placed on the upper ends of the two wooden cubes 12 oppositely arranged in the transverse direction. The screw 2 passes through the upper parts of the two wooden cubes 12 and is locked and positioned by nuts. The inner template 7 is arranged on the side template A10 and the side template A10. On the inner side of formwork B3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com