Modular movable prefabricated component production assembling combination system and combination method

A technology of prefabricated components and combined systems, applied in manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems that hinder the development of prefabricated buildings. The problem of small coverage of components can increase the usable area of the building, reduce costs, and reduce labor dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

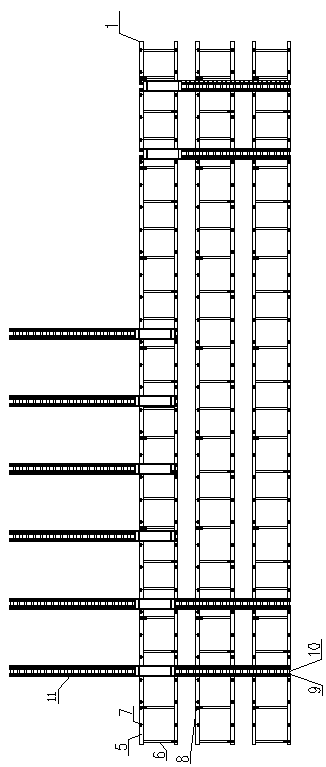

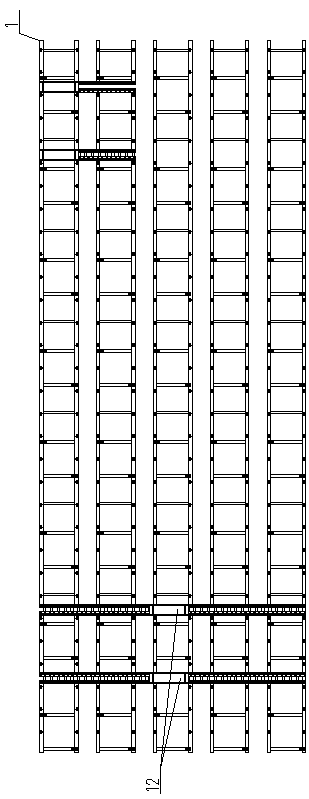

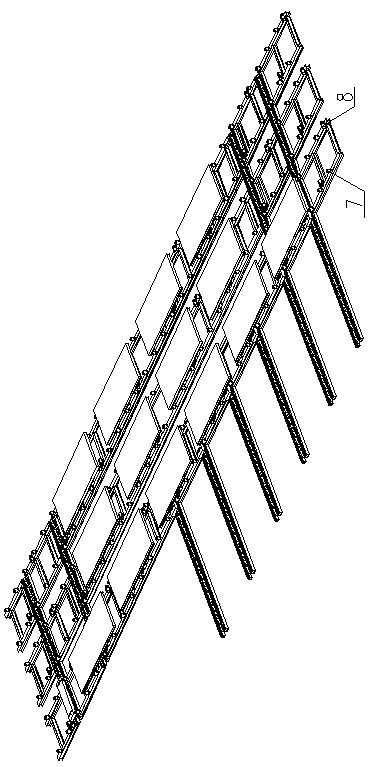

[0041] A modular mobile prefabricated component production and assembly system, which consists of: a mold table circulation system 1, a material distribution system 2, a vibrating system 3, a steaming system 4, and the mold table circulation system includes a plurality of mold table moving lines and a plurality of mold platform translation lines, the mold platform moving lines are perpendicular to the mold platform translation lines, and each of the mold platform moving lines includes two linear ground wheel foundation main beams 5 and a group of ground wheel foundations The secondary beam 6, the secondary beam of the ground wheel foundation is connected with the main beam of the ground wheel foundation to form a skeleton, and a connecting structure is arranged at the connection position, and a set of linear arrangement ground is arranged on the upper part of the main beam of the ground wheel foundation wheel 7 and a group of driving motors 8, each of the mold platform translat...

Embodiment 2

[0043] According to the modular mobile prefabricated component production and assembly combination system described in embodiment 1, the ground wheel has a support frame 13, the upper part of the support frame is provided with wheels 14, and the drive motor has a drive with an annular friction surface. Wheel 15, the ferry car is walking on the track of the shuttle car, the ferry car has a frame body 16, the bottom of the frame body is provided with a running wheel 17, and the driving device is arranged on the driving wheel, and the A jacking device 18 is arranged on the top of the ferry car.

Embodiment 3

[0045] According to the modular mobile prefabricated component production and assembly system described in embodiment 1 or 2, the moving line of the mold table is composed of multiple groups of the main beam of the ground wheel foundation, the secondary beam of the ground wheel foundation, the The ground wheel and the assembly unit formed by the drive motor, the assembly unit has a connecting structure, the mold table translation line is composed of multiple groups of the ferry car track foundation main beam, the ferry car The track foundation secondary beam and the ferry car track form a plurality of assembled units, and there are connection structures between the assembled units.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com