Color 3D printing method and device and terminal equipment

A 3D printing, color technology, used in manufacturing auxiliary devices, metal processing equipment, 3D object support structures, etc., can solve the problem of no printing or wrong printing, the printing system cannot distinguish the background information slice layer, confusion, etc., to avoid inconvenience. hit or miss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

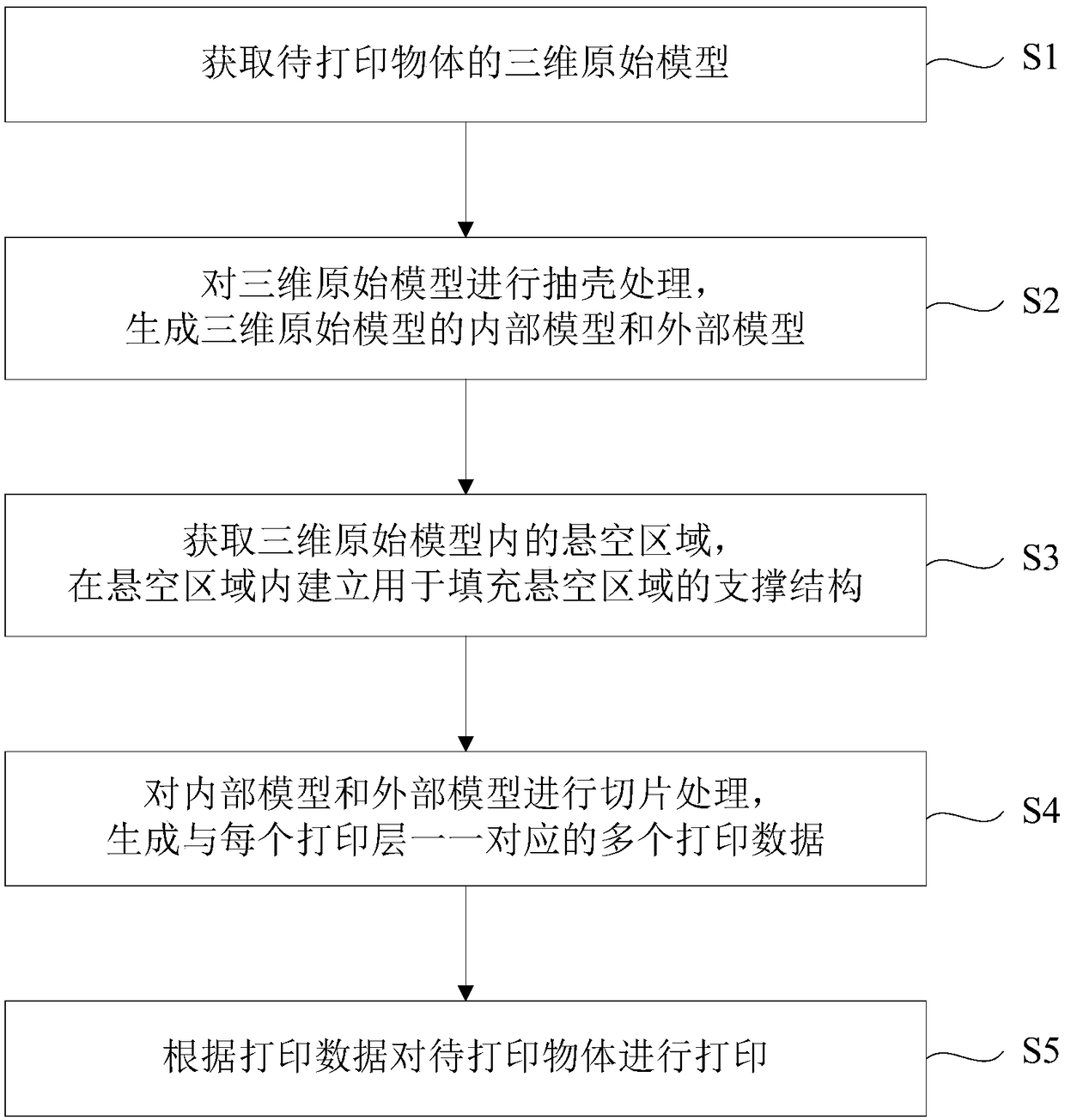

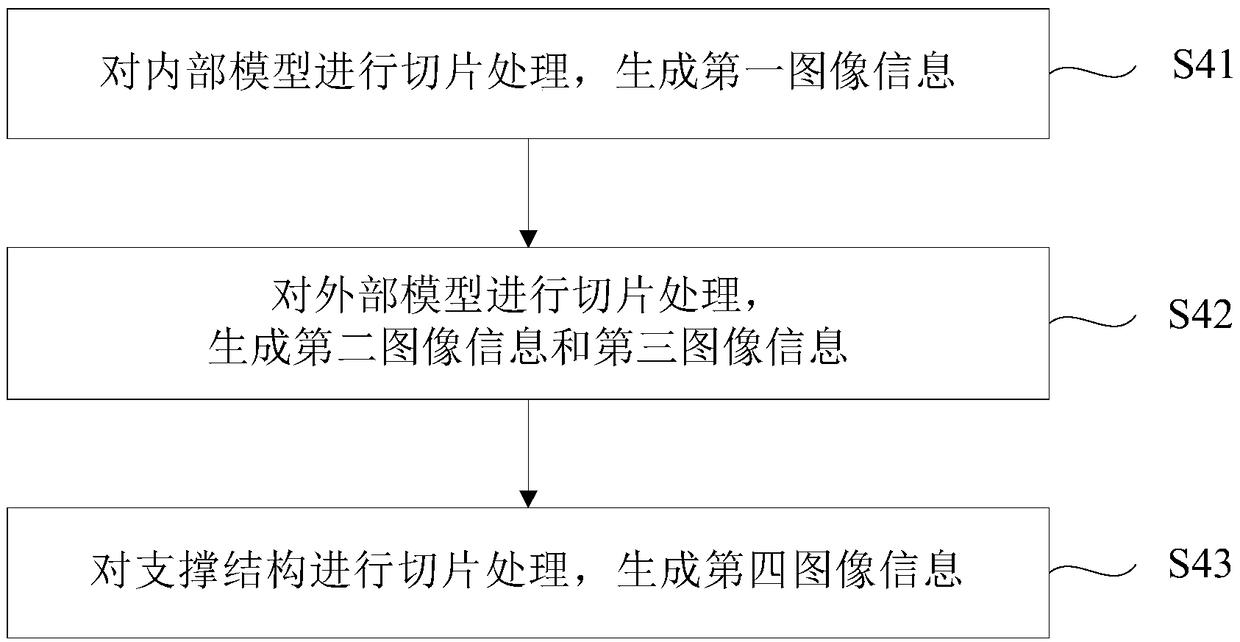

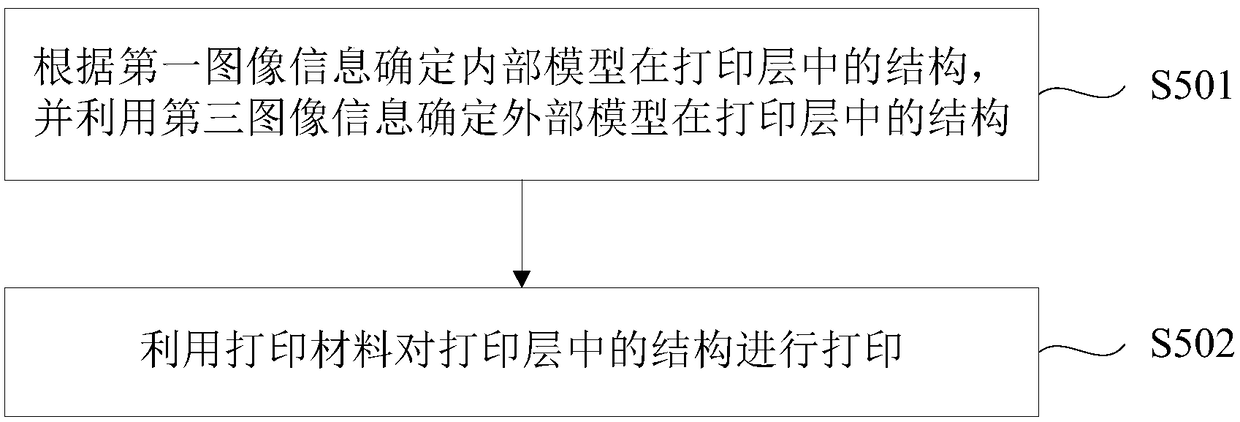

[0055] figure 1 It is a schematic flowchart of the color 3D printing method provided by Embodiment 1 of the present invention. figure 2 It is a schematic flow diagram of the slicing processing steps of the color 3D printing method provided in Embodiment 1 of the present invention. image 3 It is a schematic flowchart of the printing steps of the color 3D printing method provided in Embodiment 1 of the present invention. Figure 4 It is a schematic flowchart of the color printing part of the internal model and the external model in the printing step of the color 3D printing method provided by Embodiment 1 of the present invention. Figure 5It is a schematic structural diagram of the 3D original model of the color 3D printing method provided in Embodiment 1 of the present invention. Figure 6 It is a schematic structural diagram of an external model and an internal model formed by shelling the 3D original model of the color 3D printing method provided in Embodiment 1 of the p...

Embodiment 2

[0081] Figure 11 It is a schematic flowchart of the printing steps of the support structure of the color 3D printing method provided by Embodiment 2 of the present invention, Figure 12 It is a schematic structural diagram of the supporting structure of the color 3D printing method provided by Embodiment 2 of the present invention. Figure 13 It is a schematic structural diagram of the slicing process of the external model, the internal model and the support structure of the color 3D printing method provided by Embodiment 2 of the present invention.

[0082] refer to Figure 11 to Figure 12 As shown, on the basis of the first embodiment above, the second embodiment of the present invention also provides another color 3D printing method, which can print the suspended area in the three-dimensional original model 1, and the specific method can be:

[0083] Before the step of slicing the internal model 11 and the external model 12 to generate a plurality of print data correspon...

Embodiment 3

[0095] On the basis of the first and second embodiments above, the third embodiment of the present invention provides another color 3D printing method, which can integrate the first image information, the third image information and the fourth image information.

[0096] Specifically, before printing the object to be printed according to the printing data in Embodiment 2, it may also include:

[0097] The first image information, the third image information and the fourth image information are integrated to generate fifth image information.

[0098] It should be noted that the data storage capacity of the first image information, the third image information and the fourth image information of the binary image information in Embodiment 1 and Embodiment 2 is 1 bit, and the second image information of the 24-bit image The data storage capacity is 24bit, and the total data storage capacity is 27bit. In order to save data storage capacity, the data processing method provided by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com