Chemical-prevention gloves and production method thereof

A production method and glove technology, applied to other household appliances, household components, household appliances, etc., can solve the problems of poor chemical resistance of gloves, achieve excellent mechanical and chemical properties, ensure hand safety, and reduce hand fatigue Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

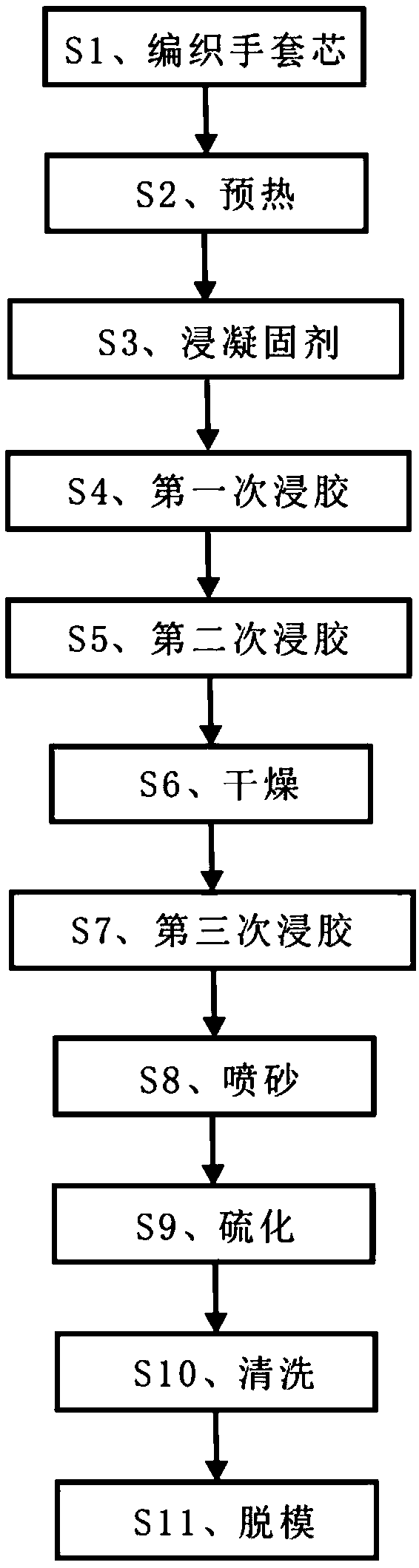

[0045] S1, braided glove core;

[0046] S2. Preheating: Select a suitable hand mold according to the specifications of the gloves to be produced, put a glove core on the hand mold, and perform preheating. The preheating temperature range is 20-45°C;

[0047] S3. Soaking the coagulant: put the glove core on the hand mold and immerse it in the coagulant and dry it;

[0048] S4. The first dipping: dip the glove core dried in step S3 into the first latex tank for dipping, and perform a uniform rubber treatment. The temperature range in the first latex tank is 28-33°C;

[0049] S5, the second dipping: dip the glove core after the first dipping in step S4 into the second latex tank for dipping, and perform a uniform rubber treatment. The temperature range in the second latex tank is 30-40°C ;

[0050] S6, drying: drying the glove core after the second dipping in step S5;

[0051] S7. Dipping for the third time: immerse the dried glove core in step S6 in the third latex tank for...

Embodiment 1-21

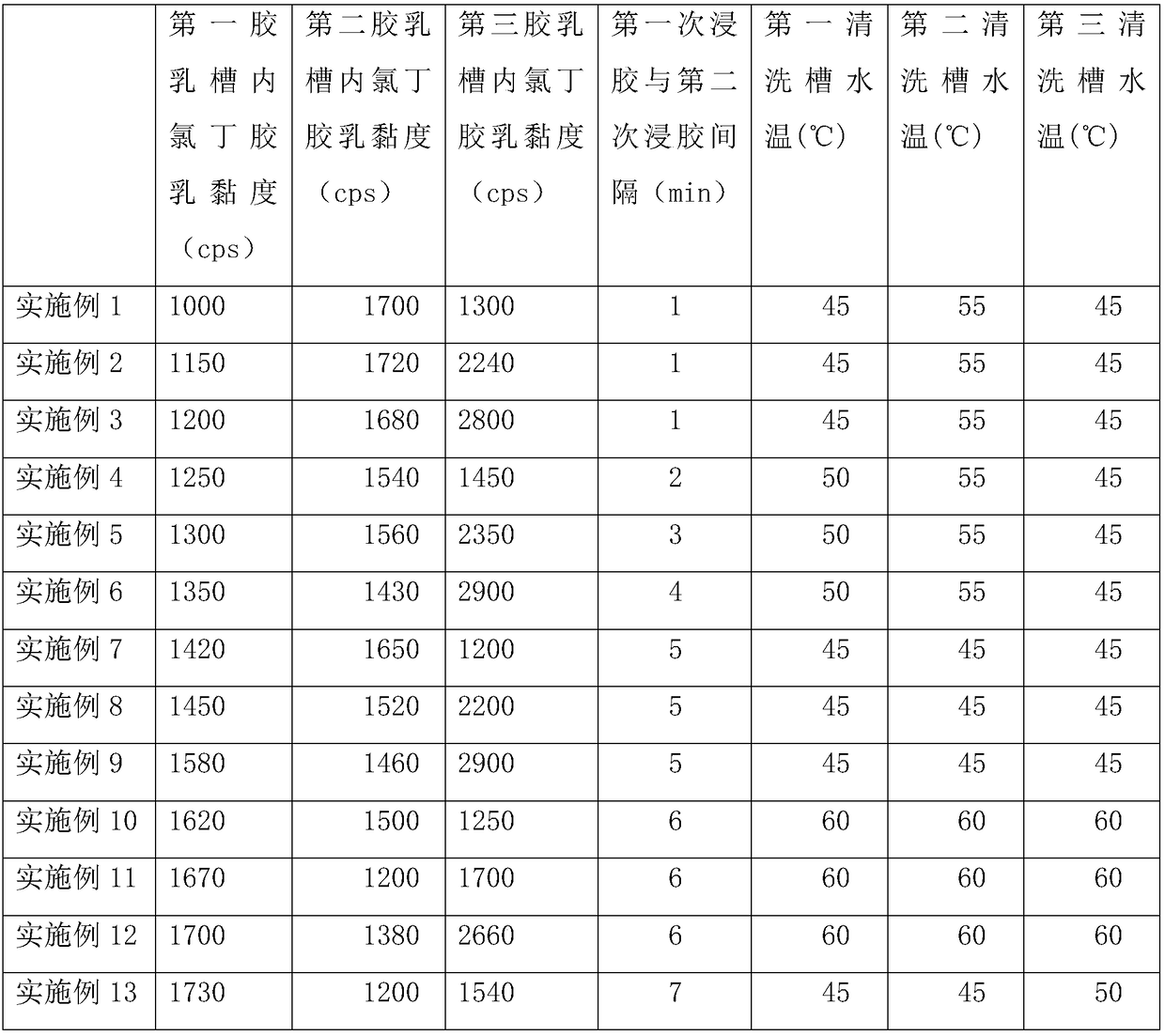

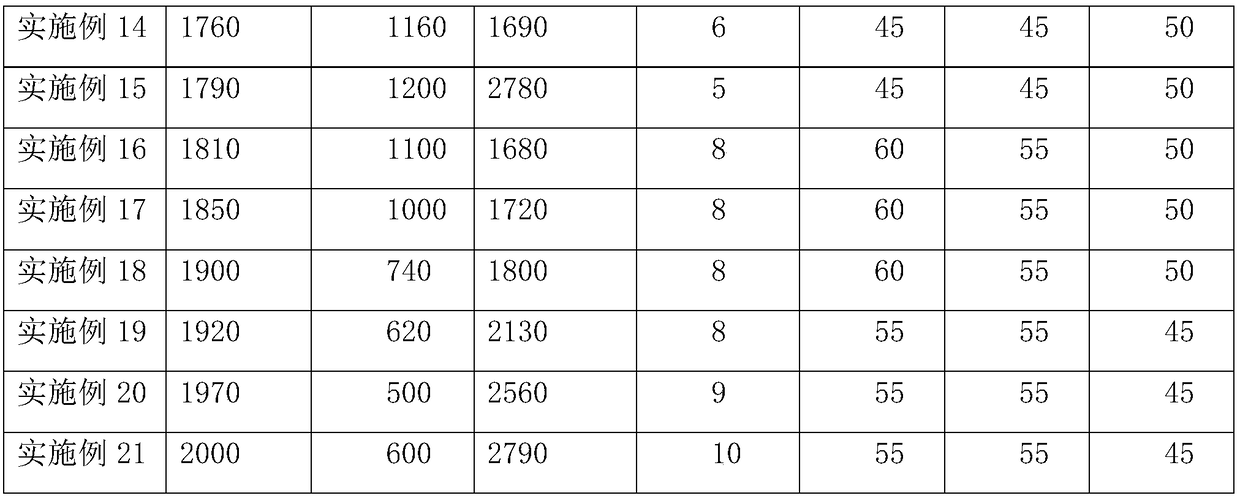

[0065] Table 1 embodiment 1-21 experimental conditions

[0066]

[0067]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com