Multi-specification plate sorting separate-packaging robot and sorting separate-packaging method

A multi-specification, robotic technology, applied in sorting, packaging, packaging protection and other directions, can solve the problems of plate punching, impact, low efficiency of lifting and conveying lines, etc., to improve work efficiency, good continuity, improve space rate and adjust. Take the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

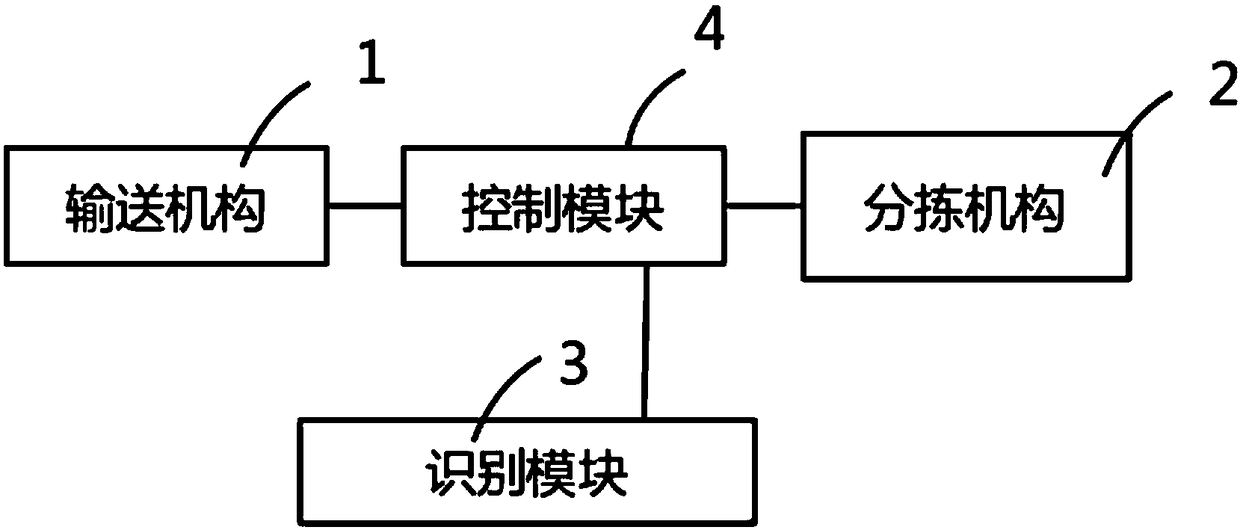

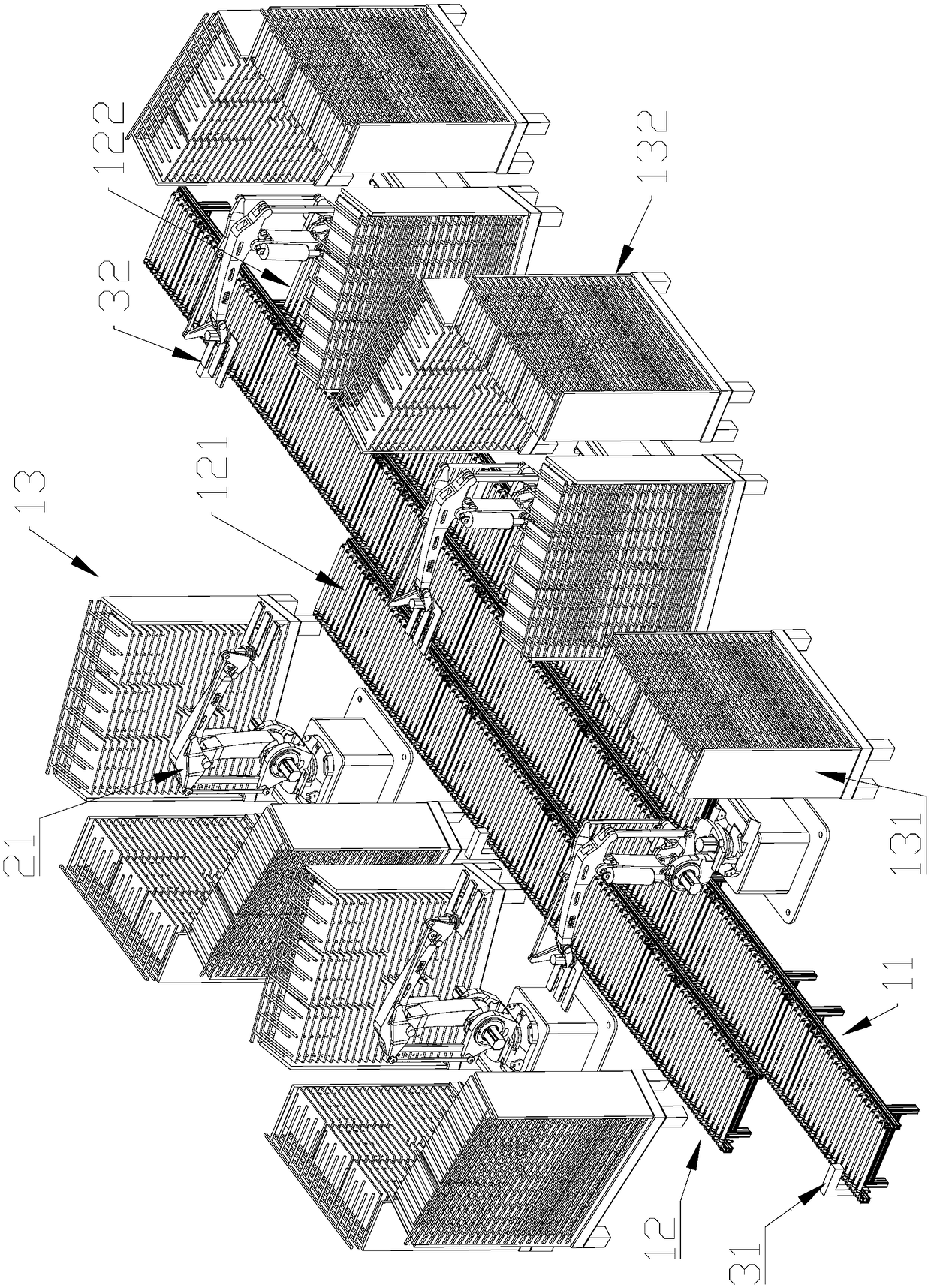

[0032] Such as figure 1 As shown, the multi-standard plate sorting and packaging robot of the first embodiment of the present invention includes:

[0033] The conveying mechanism 1 is used to receive the plates to be sorted and convey them to the packing position, including the main conveying line 11 extending from the receiving end to the packing position, the buffer conveying line 12 located on one side or both sides of the main conveying line, and the buffer conveying A plurality of cache racks 13 beside the line;

[0034] Sorting mechanism 2: used to transfer plates on the main conveying line 11, buffer conveying line 12 and buffer rack 13, including a sorting manipulator 21 arranged next to each buffer rack;

[0035] The identification module 3 is used to identify the characteristic information and packaging information of the plate, including a characteristic information reading unit 31 located at the starting end of the main conveying line and a packaging information r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com