Moving wheel assembly on grain absorbing machine

A technology for moving wheels and components, which is applied in the direction of casters, wheels, conveyors, etc., which can solve the problems affecting the actual operation, large vibration of the grain suction machine, and poor buffering effect, so as to achieve good buffering effect, improve buffering performance, and prevent volatilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

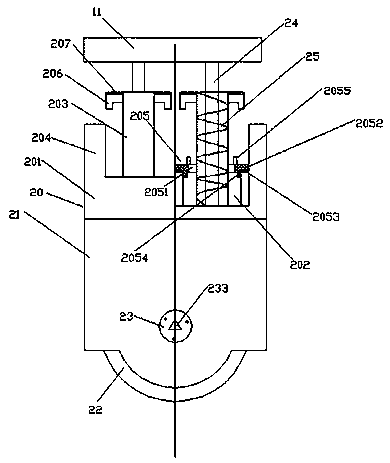

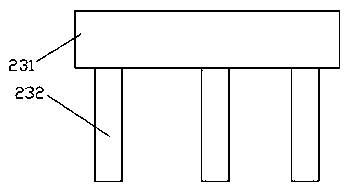

[0018] Reference Figure 1-2 , A movable wheel assembly on a grain suction machine, set at the bottom of the grain suction machine, characterized in that it includes a support base 20, together with wheel frames 21 on both sides of the support base 20, the wheel frame 21 and the support base 20 are welded It can also be integrally formed in other ways; a wheel 22 is provided between the two wheel carriers 21 through a wheel axle, and the wheel 22 can rotate freely; the two side ends of the wheel axle are triangular, and the wheel carrier 21 A fixer 23 is provided on the upper part, and the fixer 23 is used to fix the rotation of the wheel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com