Automatic returning device for nonwoven fabric

A non-woven fabric and automatic technology, applied in the field of non-woven fabric automatic return device, can solve the problems of waste of resources, occupation of labor costs, messy non-woven fabrics, etc., and achieve the effect of improving efficiency and liberating labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

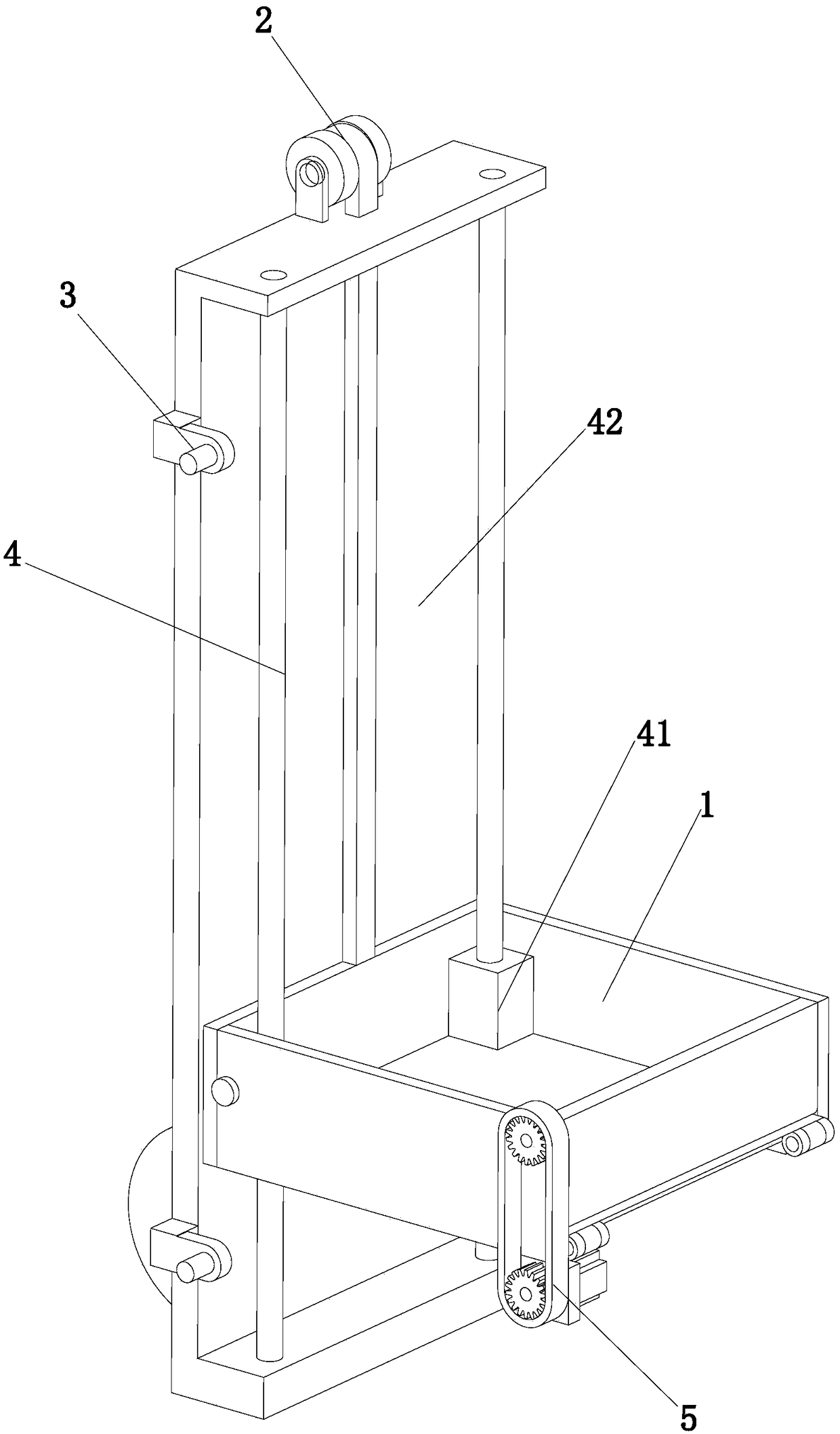

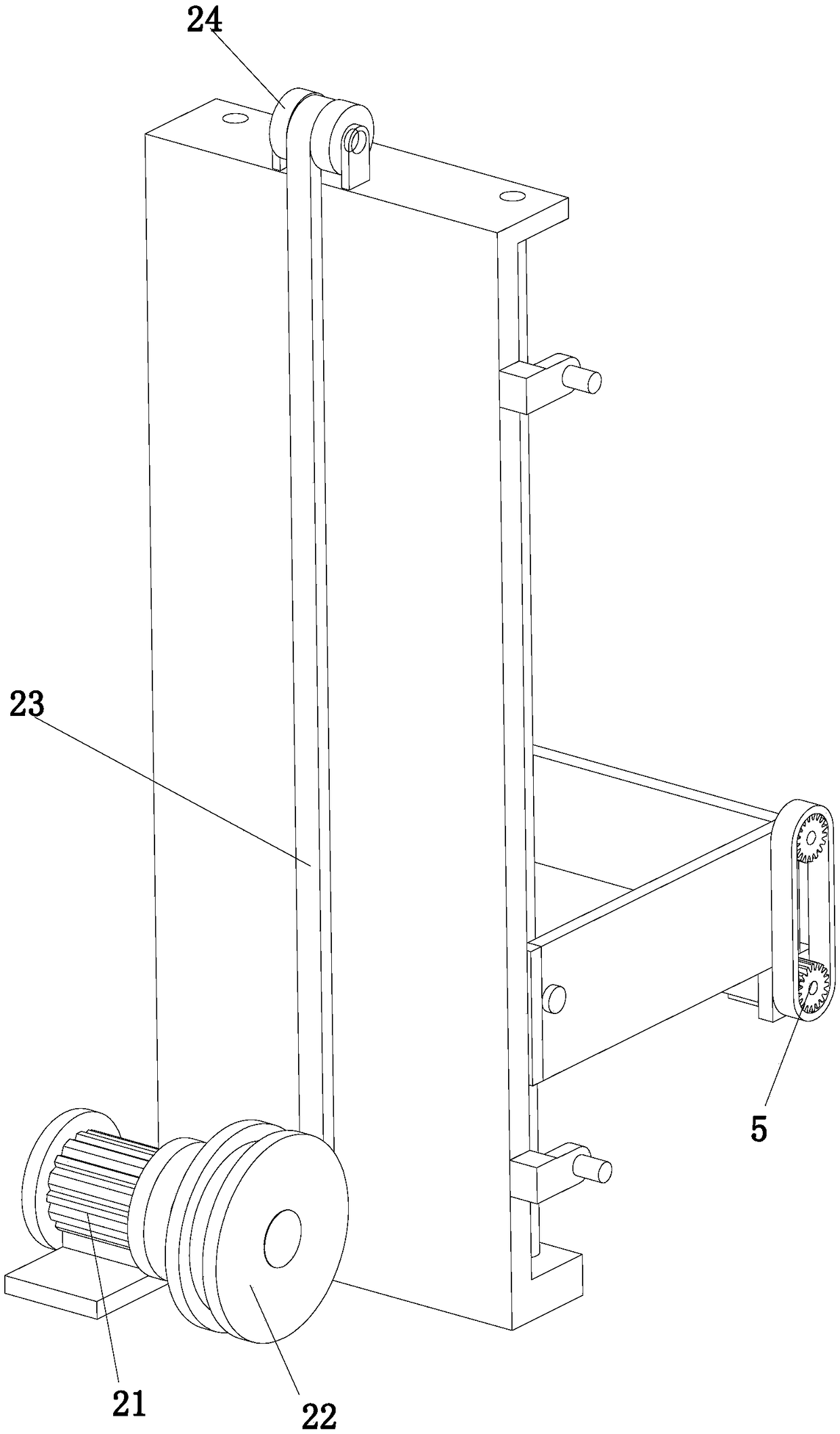

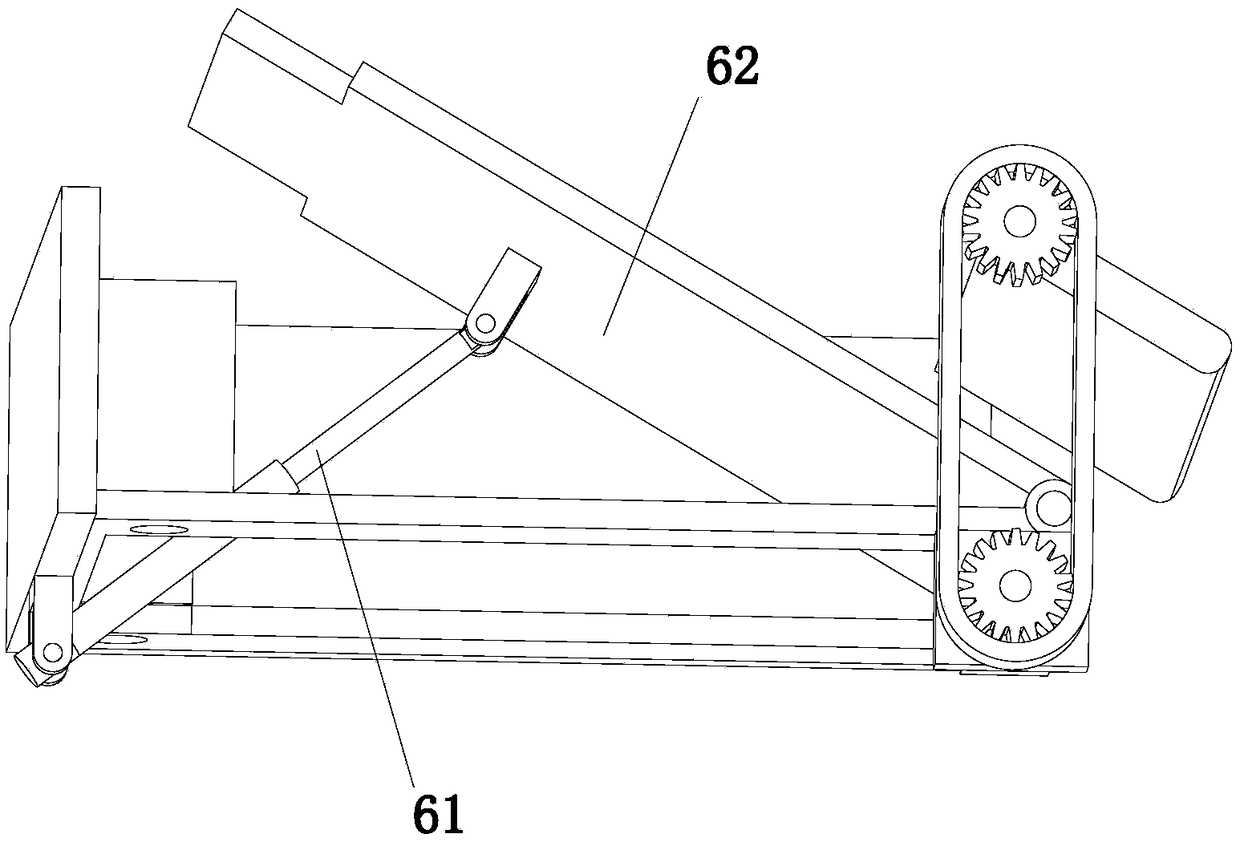

[0021] refer to Figure 1 to Figure 4 As shown, the present invention is an automatic non-woven fabric return device, which includes a storage device for accommodating non-woven fabrics, a lifting device and a control device for driving the storage device up and down, and the storage device includes a storage box 1, An overturning assembly for lifting the non-woven fabric in the storage box 1 and an opening and closing assembly for opening and closing the storage box 1. The lifting device includes a guide assembly and a linkage assembly 2. The storage box 1 and the guide The components are slidingly matched, the linkage component 2 is hinged with the top of the storage box 1, the control device includes a controller and a sensor component electrically connected with the controller, and the opening and closing component is provided with a hinged connection with the top of the storage box 1 The switch door 55 and the rotating assembly 5 for driving the switch door 55 to rotate, ...

Embodiment 2

[0029] refer to Figure 1 to Figure 4As shown, the present invention is an automatic non-woven fabric return device, which includes a storage device for accommodating non-woven fabrics, a lifting device and a control device for driving the storage device up and down, and the storage device includes a storage box 1, An overturning assembly for lifting the non-woven fabric in the storage box 1 and an opening and closing assembly for opening and closing the storage box 1. The lifting device includes a guide assembly and a linkage assembly 2. The storage box 1 and the guide The components are slidingly matched, the linkage component 2 is hinged with the top of the storage box 1, the control device includes a controller and a sensor component electrically connected with the controller, and the opening and closing component is provided with a hinged connection with the top of the storage box 1 The switch door 55 and the rotating assembly 5 for driving the switch door 55 to rotate, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com