Method for constructing huge underground powerhouse machine pit in high ground stress and basalt geology conditions

A technology with geological conditions and high ground stress, applied in excavation, foundation structure engineering, sheet pile walls, etc., can solve problems such as high safety risks, high hollowing rate, and large deformation of excavated surrounding rocks, so as to ensure stability and safety It is beneficial to excavation forming and reducing the scale of blasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

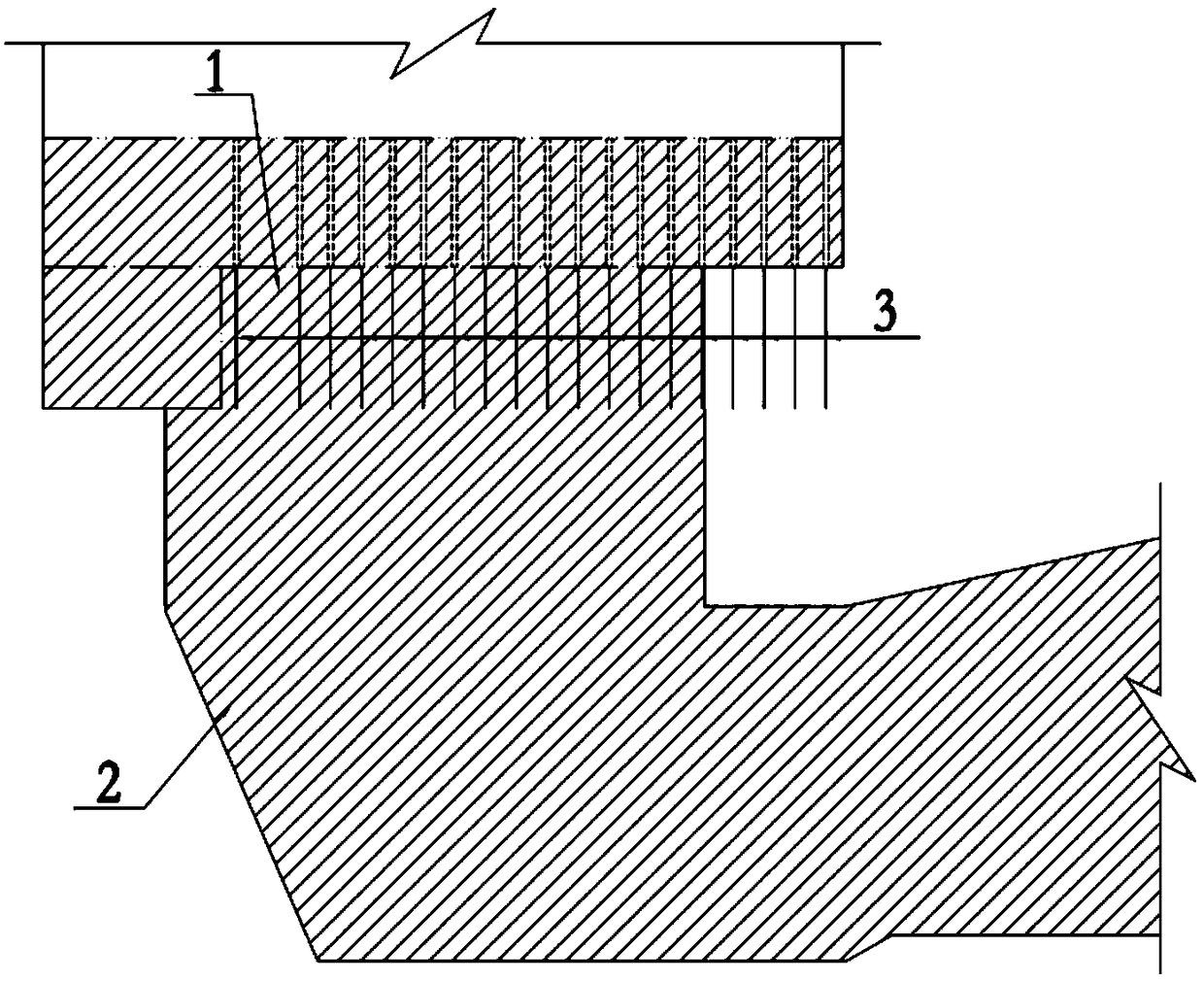

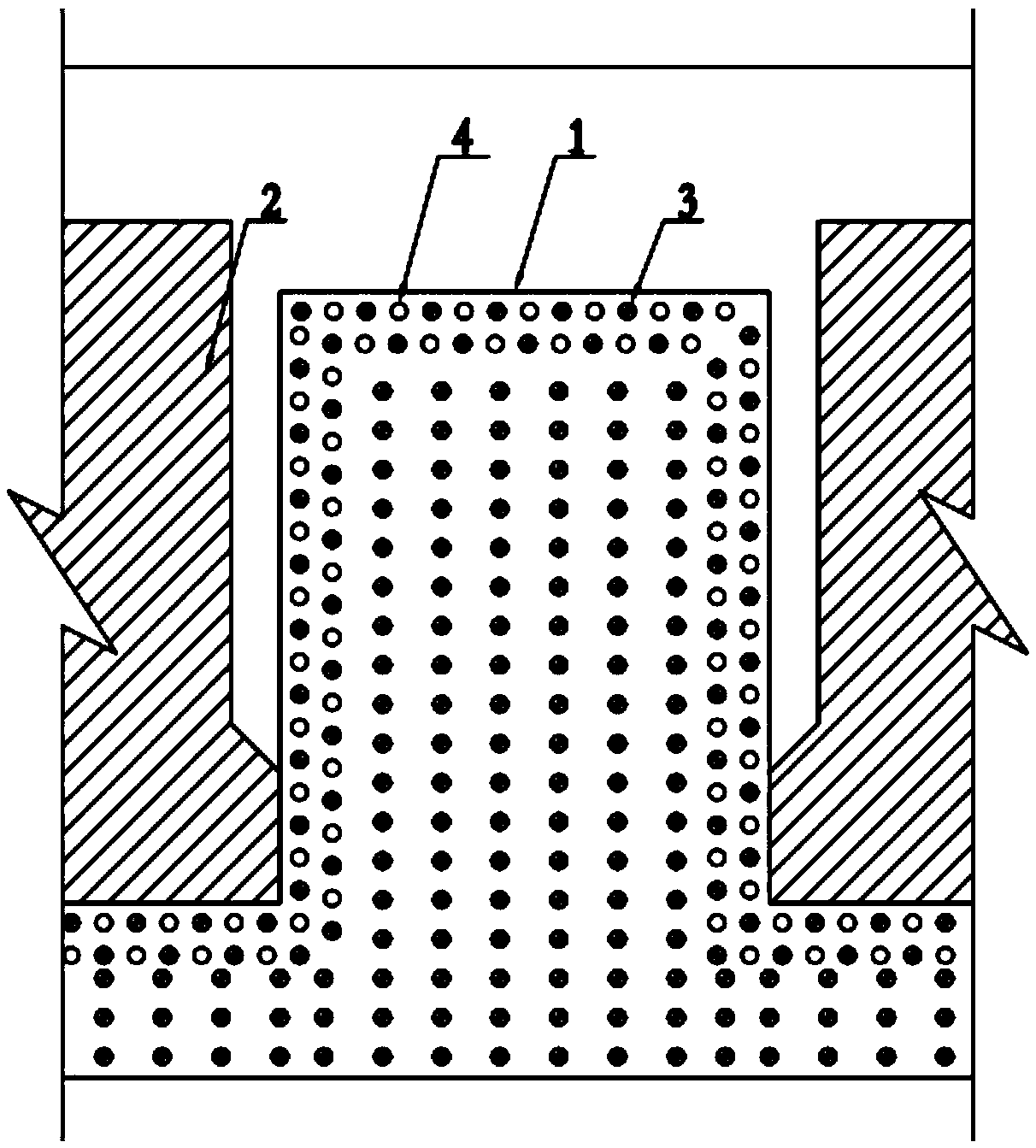

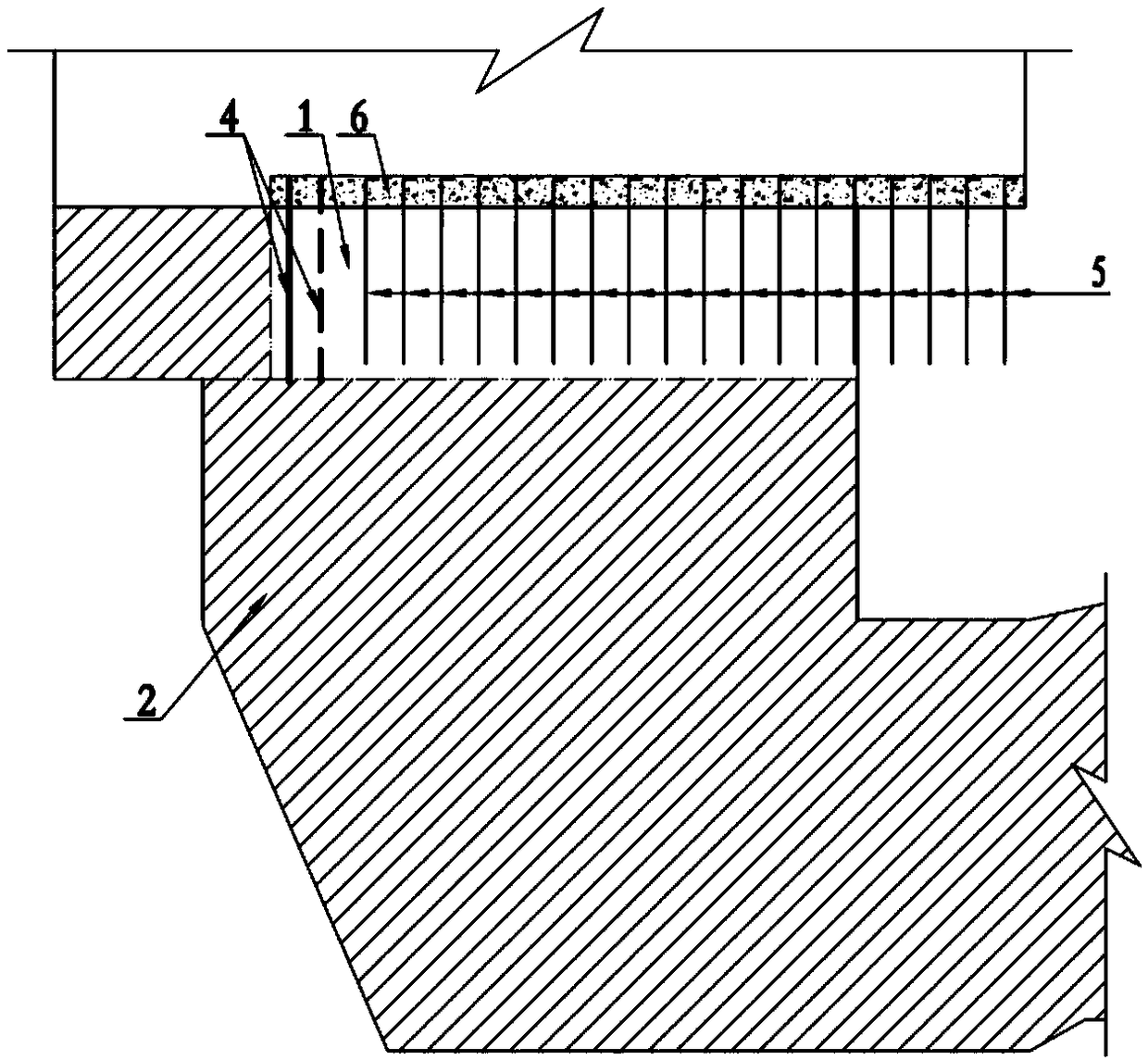

[0033] combine Figure 1 to Figure 7 , the following is a specific excavation construction of a machine pit for an underground powerhouse. The plant is built under high ground stress and basalt geological conditions, and the construction method for excavating a machine pit for an underground powerhouse specifically includes the following steps:

[0034] 1. Pre-support of pier

[0035] Before the machine pit 2 is excavated, the pier 1 is pre-supported by the combination of countersunk anchor rod 3 + lock anchor rod 4 + cover weight concrete 6 + prestressed anchor cable 7 to ensure that the pier 1 is under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com