Masonry well chamber and construction method

A well room and masonry technology, applied in construction, artificial islands, water conservancy projects, etc., can solve the problems of early inspection of well construction quality, high maintenance costs, small workload, etc., to improve the efficiency of plastering construction, save materials, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

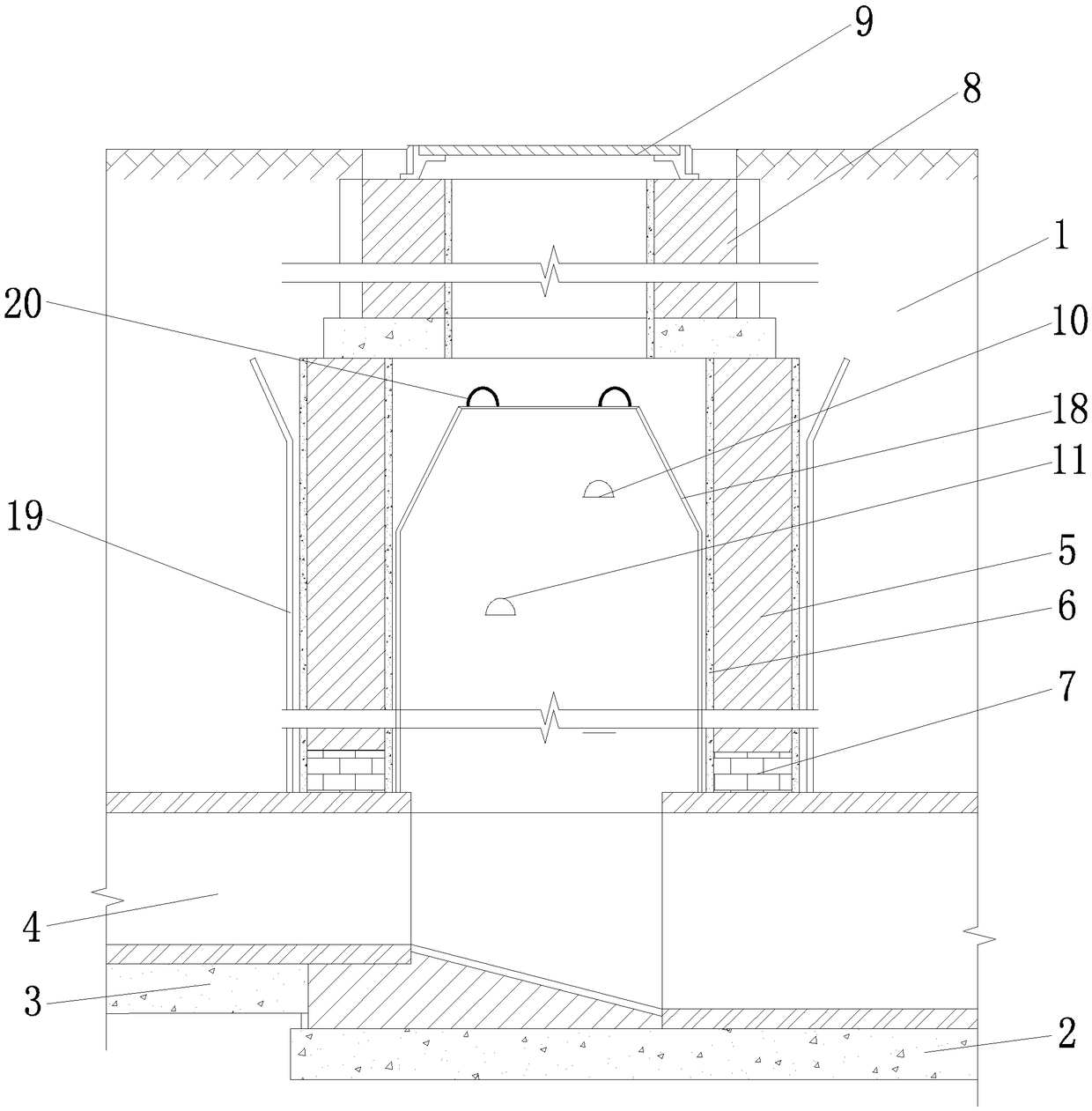

[0045] Such as figure 1 As shown, the masonry well chamber includes a well body 5 arranged in the excavation tank chamber 1, a shaft 8 is arranged on the upper part of the shaft body 5, a well cover 9 is provided at the end of the shaft shaft 8, and the inner and outer sides of the shaft body 5 are arranged There is a plastering surface 6, the thickness of the plastering surface 6 is 20mm, several foot pockets 11 are arranged on the plastering surface 6, and the height of the foot pockets 11 is 10cm. Steps 10 are arranged under the foot pockets 11, and the vertical interval of the step 10 is 360mm, and the horizontal interval is 300mm; The foot socket 11 is convenient for workers to climb ladders and walk in the later stage, and improves the safety of later maintenance and construction.

[0046] The well chamber foundation 2 and the pipeline 4 are set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com