Compacting compound rock breaking heading machine with arbitrary fracture surfaces

A roadheader and cross-section technology, which is applied to mining equipment, earthwork drilling, tunnels, etc., can solve the problems of high construction costs of non-circular cross-sections, and achieve the effects of avoiding adverse effects, saving internal space, and ingenious structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

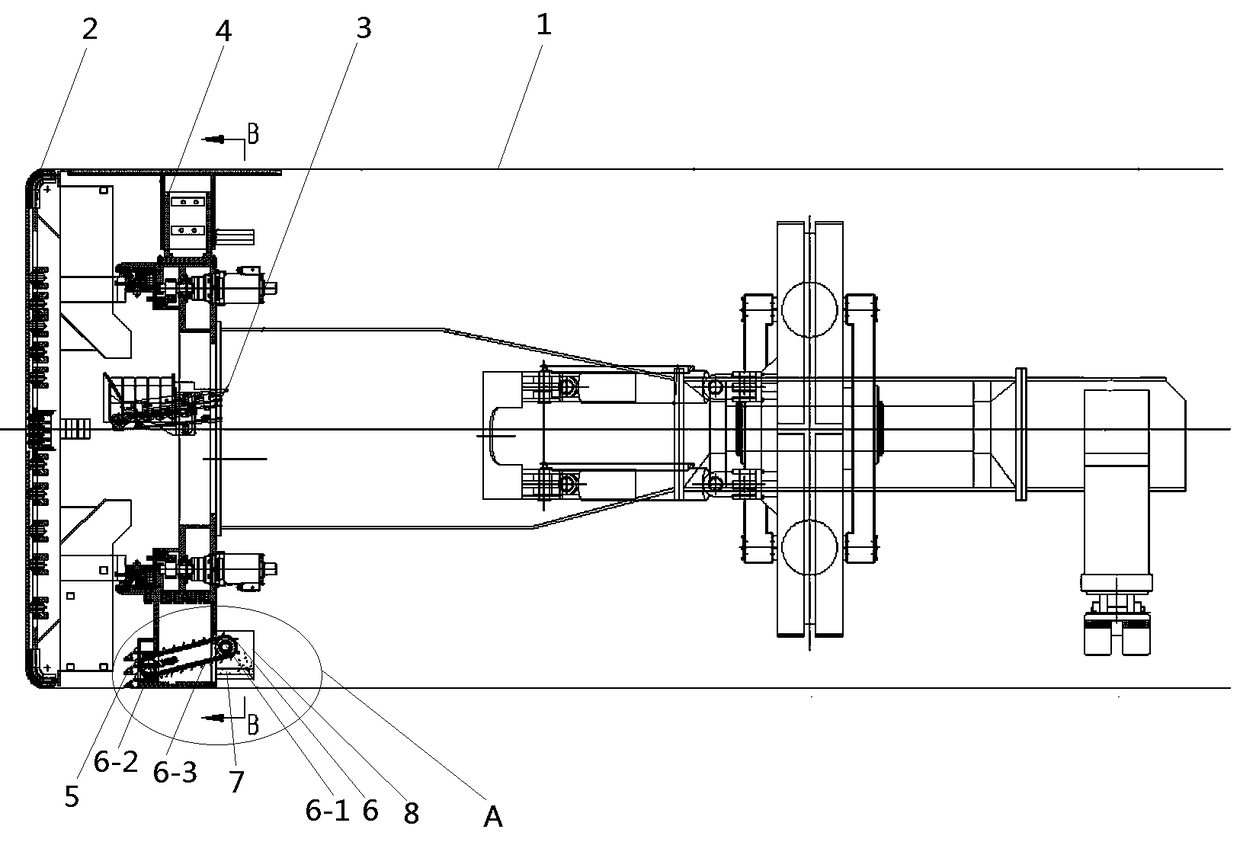

[0017] Embodiment 1, pressure-beating composite rock-breaking arbitrary section tunneling machine, such as figure 1 As shown, it includes the cutter head 2 at the front end of the shield body 1 and the slag discharge belt conveyor 3 connected with the cutter head 2. The rock slag in the excavation area is transported to the slag discharge belt conveyor 3, and the rock slag is transported to the outside along with the slag discharge belt conveyor 3.

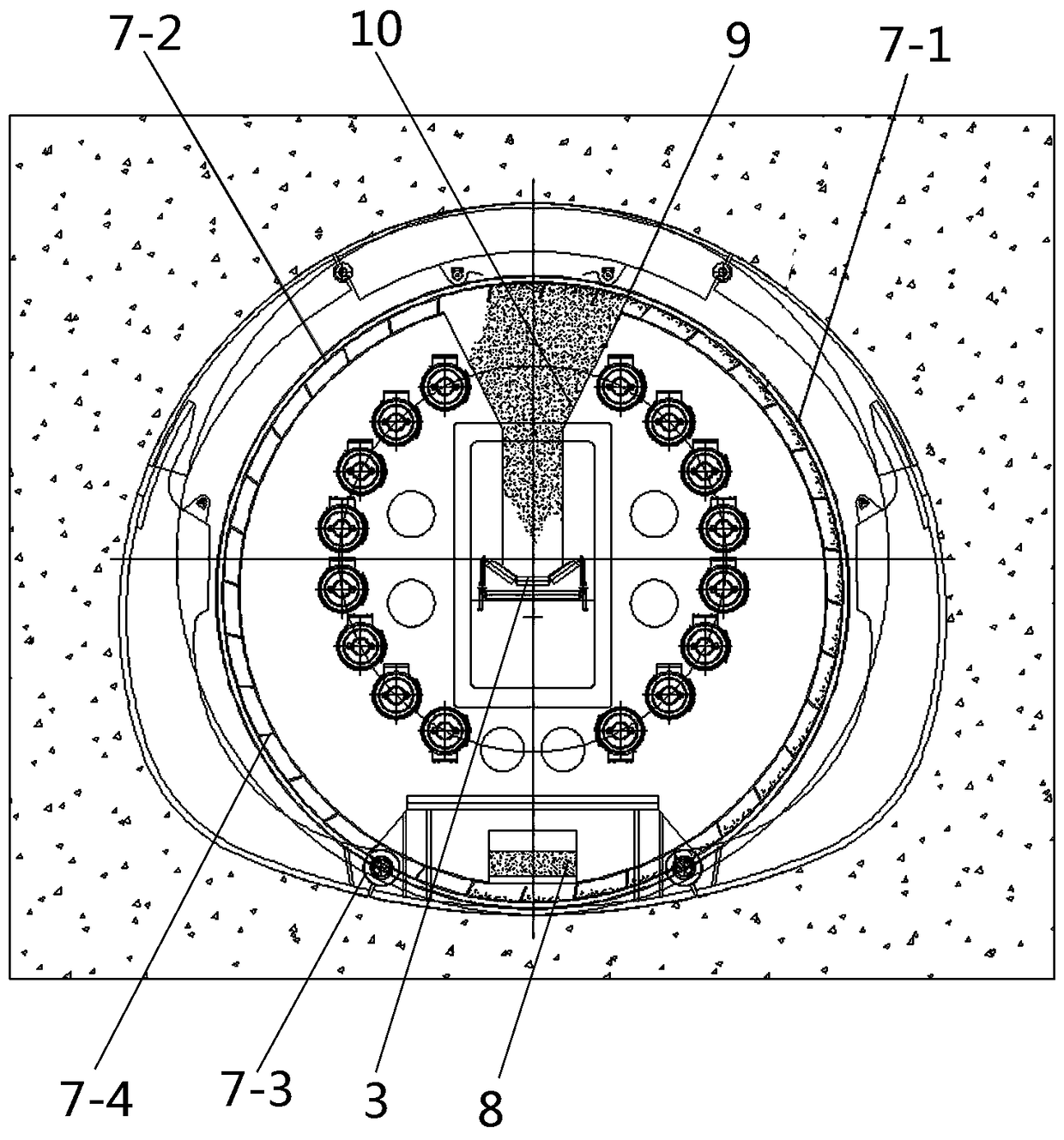

[0018] Such as image 3 As shown, the shield body 1 behind the cutter head 2 is provided with a contour shield 4, and the contour shield 4 is provided with an impactor 5. Setting the contour shield behind the cutterhead 2 can provide a rock-breaking support for the tunnel excavation of the corresponding section, and the impactor 5 arranged on the contour shield 4 cooperates with the hob on the cutterhead 2 to excavate the tunnel of the corresponding section. The impactor 5 trims the remaining under-excavated part after the excav...

Embodiment 2

[0021] Example 2, the roadheader for any section of the composite rock breaking by pressure, the size of the contour shield 4 matches the size of the tunnel section, such a design can avoid setting the impactor 5 obliquely, as long as it is arranged vertically on the contour shield 4 The impactor 5 can trim the remaining under-excavated part without adjusting the angle of the impactor 5, and can avoid the adverse effect of the oblique impact on the impactor 5.

[0022] Other structures of this embodiment are the same as those of Embodiment 1.

Embodiment 3

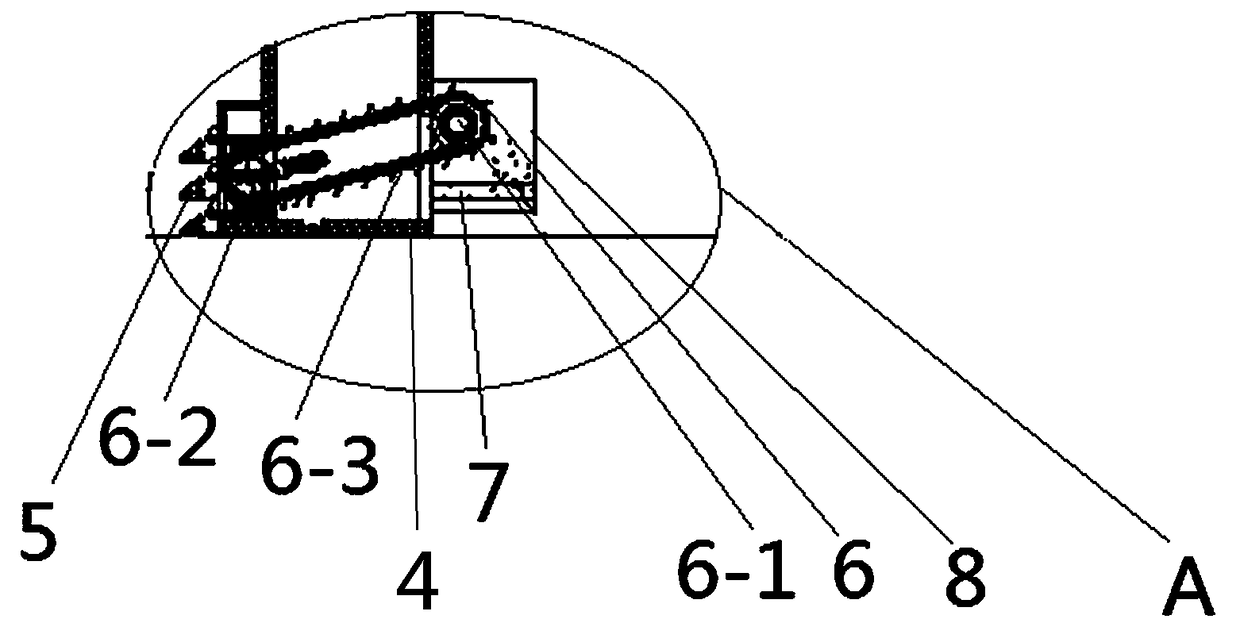

[0023] Embodiment 3, the roadheader with any cross-section of the composite rock breaking by pressure, the slag transfer device 6 includes a slag transfer motor 6-1 and a driven wheel 6-2, and the slag transfer motor 6-1 and the driven wheel 6-2 pass through scales Plate with 6-3 transmission connection. The scale belt is set as the transmission part of the slag converter, which can transport rock slag reliably and efficiently.

[0024] Other structures of this embodiment are the same as those of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com