An automotive direct current electronic water pump

A technology for electronic water pumps and automobiles, applied to pumps, parts of pumping devices for elastic fluids, pump components, etc., can solve the problems of slow flow rate of cooling water and large instantaneous noise, and achieve the goal of avoiding instantaneous noise, fast flow rate, The effect of the fast delivery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

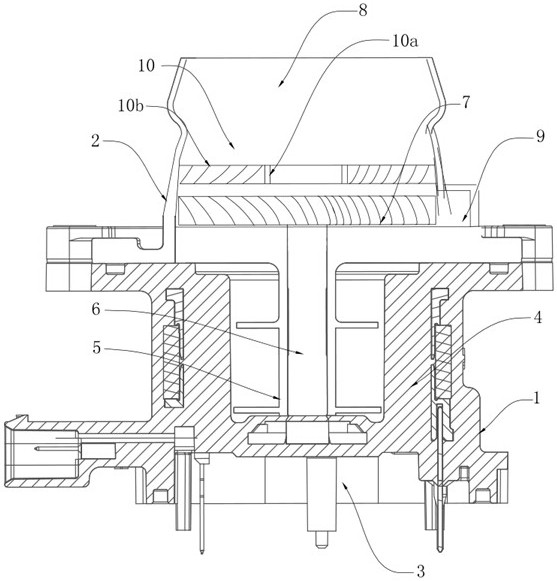

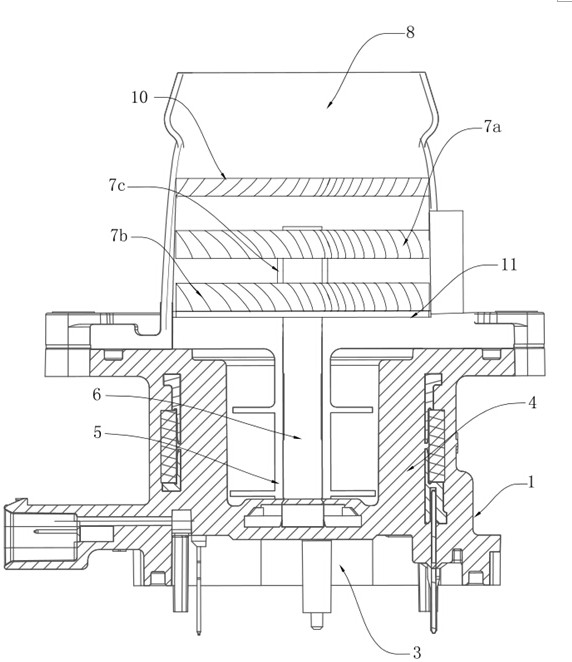

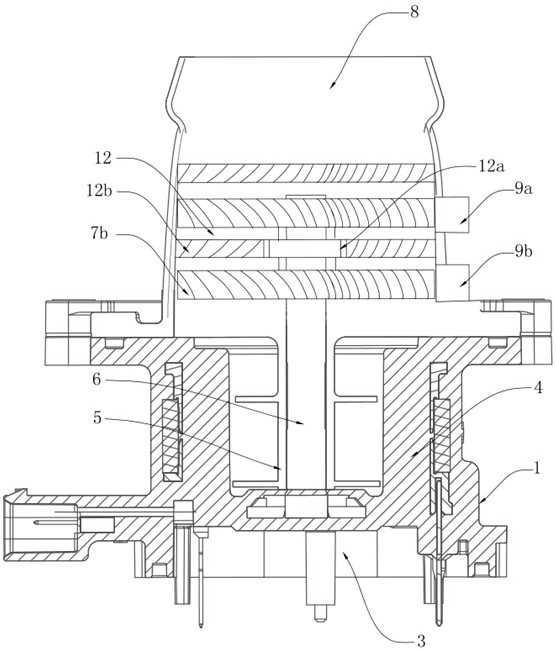

[0025] like figure 1 As shown, the present embodiment provides an automotive direct current electronic water pump, including a pump body 1, a cover body 2, an electric control board 3, a stator 4, a rotor 5, a rotating shaft 6 and an impeller 7; the cover body 2 is fixedly mounted on the pump Body 1, wherein the cover body 2 is provided with a water inlet pipeline 8 along the axial direction, and a water outlet pipeline 9 is provided along the tangential direction, and the water inlet pipeline 8 and the water outlet pipeline 9 are both communicated with the inner cavity of the cover body 2 , the electric control board 3 and the stator 4 are encapsulated in the inner cavity of the pump body 1 through epoxy resin glue, and the two are electrically connected, and the rotating shaft 6 is fixed to the pump body 1 along the axis of the stator 4 with one end , the other end extends to the inner cavity of the cover body 2, the rotor 5 is set in the inner cavity of the pump body 1 and ...

Embodiment 2

[0030] like figure 1 As shown, in order to get closer to the impeller structure of the turboshaft engine and further improve the cooling water transfer efficiency and flow rate, the inner diameter of the water inlet pipeline 8 and the connection with the cover body 2 in this embodiment is equal to the outer diameter of the impeller 7; The structure is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0032] preferred, such as figure 1 As shown, in order to further reduce the noise level of the automotive DC electronic water pump provided in this embodiment, considering that the high-speed cooling water will also generate some noise when it first contacts the first guide impeller 10, the first set of guide vanes in this embodiment It is made of vulcanized rubber material. On the one hand, the vulcanized rubber can work stably for a long time. On the other hand, it has certain elasticity and can effectively absorb impact force, thereby further reducing the level of instantaneous noise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com