Method for installing and constructing 56-inch oil and gas conveying pipelines

A technology for conveying pipelines and construction methods, which is applied in the directions of pipeline laying and maintenance, pipes/pipe joints/pipes, mechanical equipment, etc. The effect of increasing stability, strong construction standardization, and reducing the probability of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

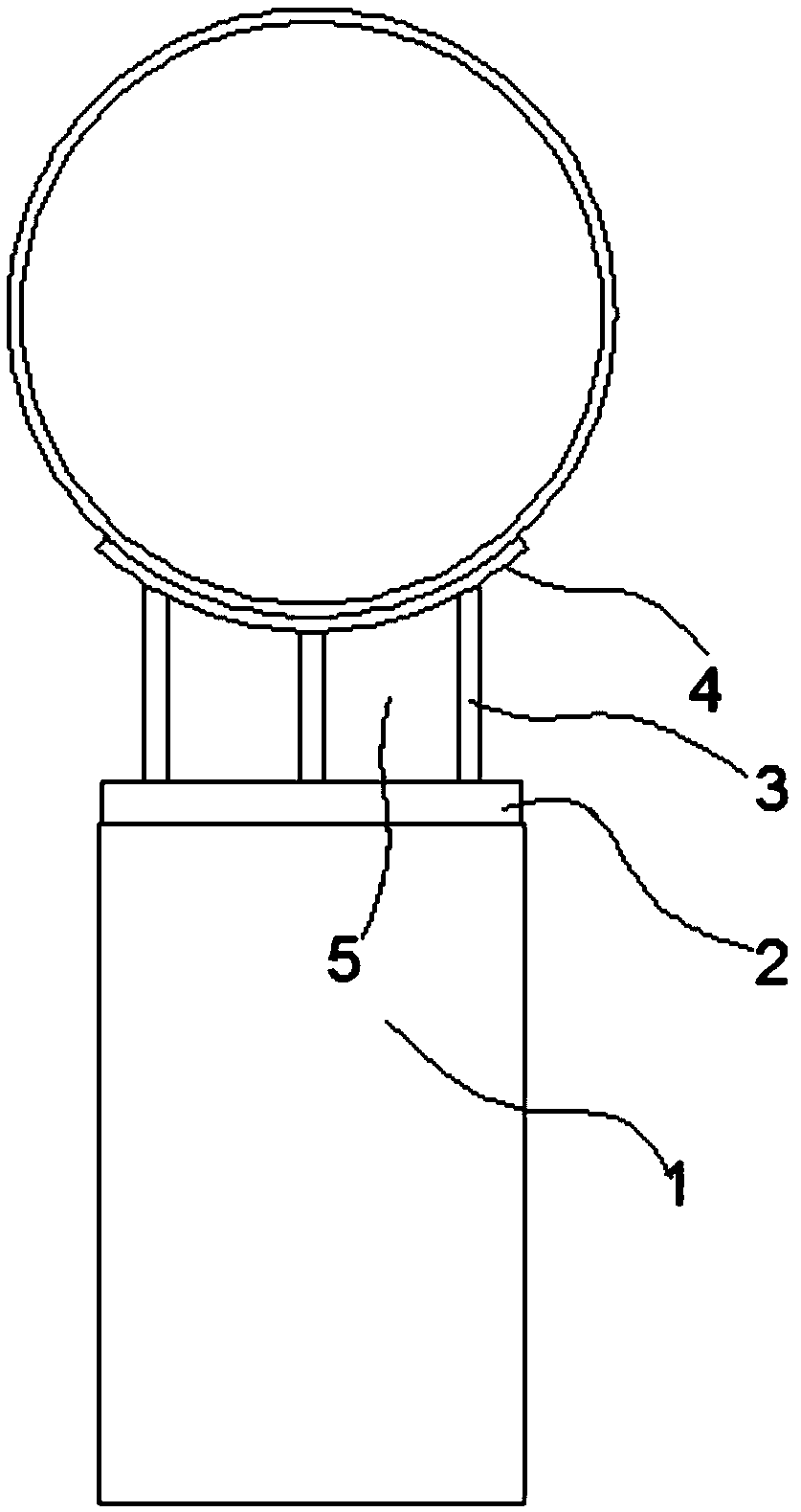

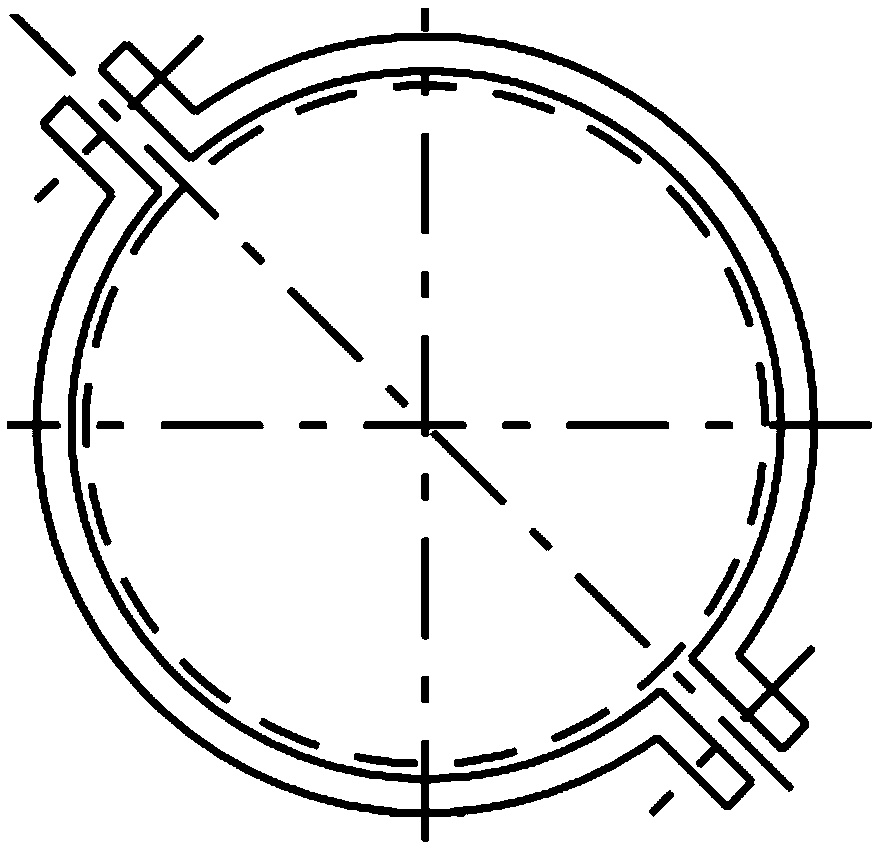

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] The installation and construction method of the 56-inch oil and gas pipeline of the present invention comprises the following steps:

[0026] A. Check the pipeline to be installed. Specifically, after the pipeline arrives at the site, QC inspection will be carried out first, and the technician will check the pipeline again before installation, and check the surface of the pipeline to ensure that there are no cracks, pores, slag inclusions, and sticky sand. , missing welding, heavy skin and other defects, the depth of the surface depression is less than 1.5mm, and the maximum length of the depression is less than 5% of the circumference of the pipe and less than 40mm.

[0027] B. The 56-inch pipe has two wall thickness specifications of 25.4mm and 28.58mm, and it is forbidden to mix and substitute. Many pipes in the pipeline have the same wall th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com