Z-shaped tempering box firewood and grass energy-saving furnace

An energy-saving furnace, glyph technology, applied in the direction of household furnace/stove, lighting and heating equipment, solid heating fuel, etc., can solve the problems of increasing pressure and no change of tempering box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

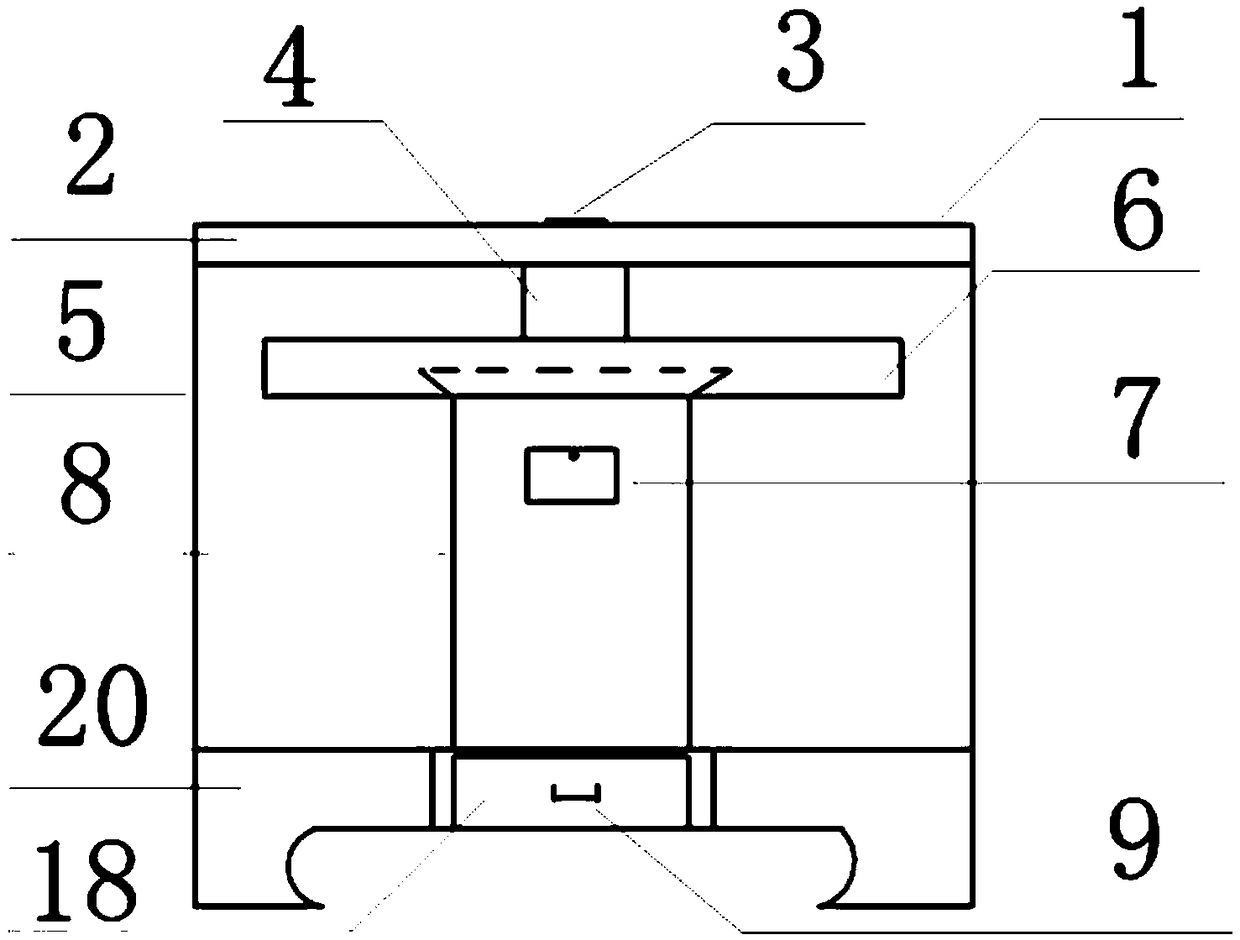

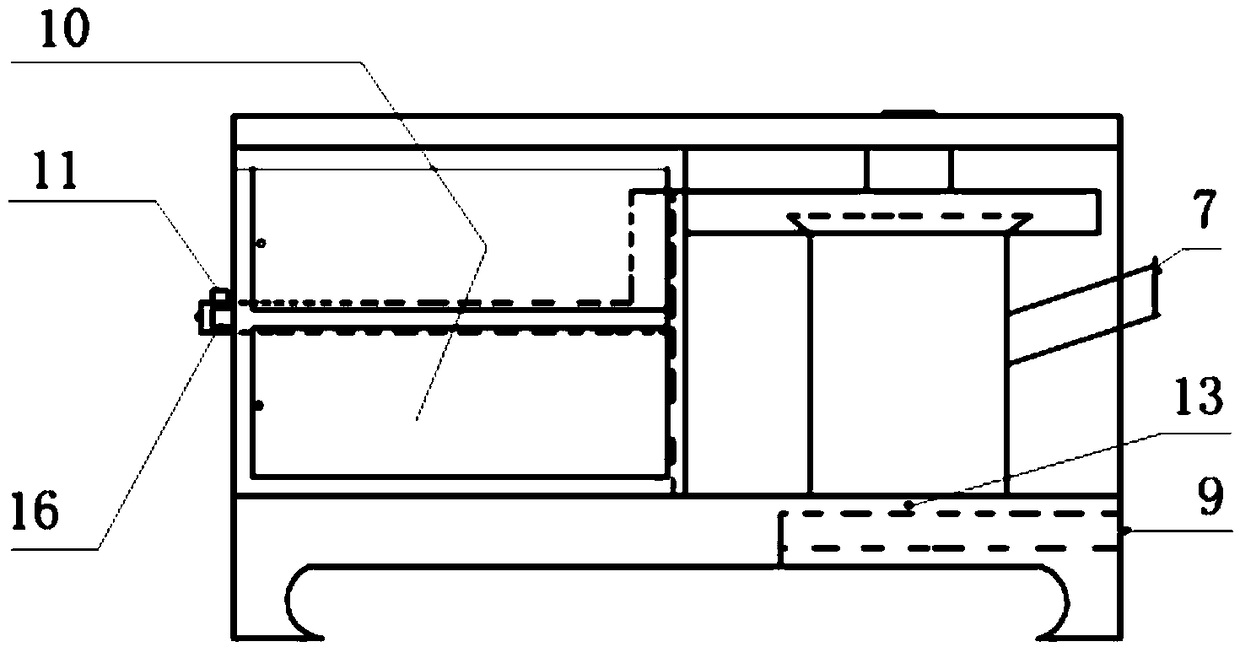

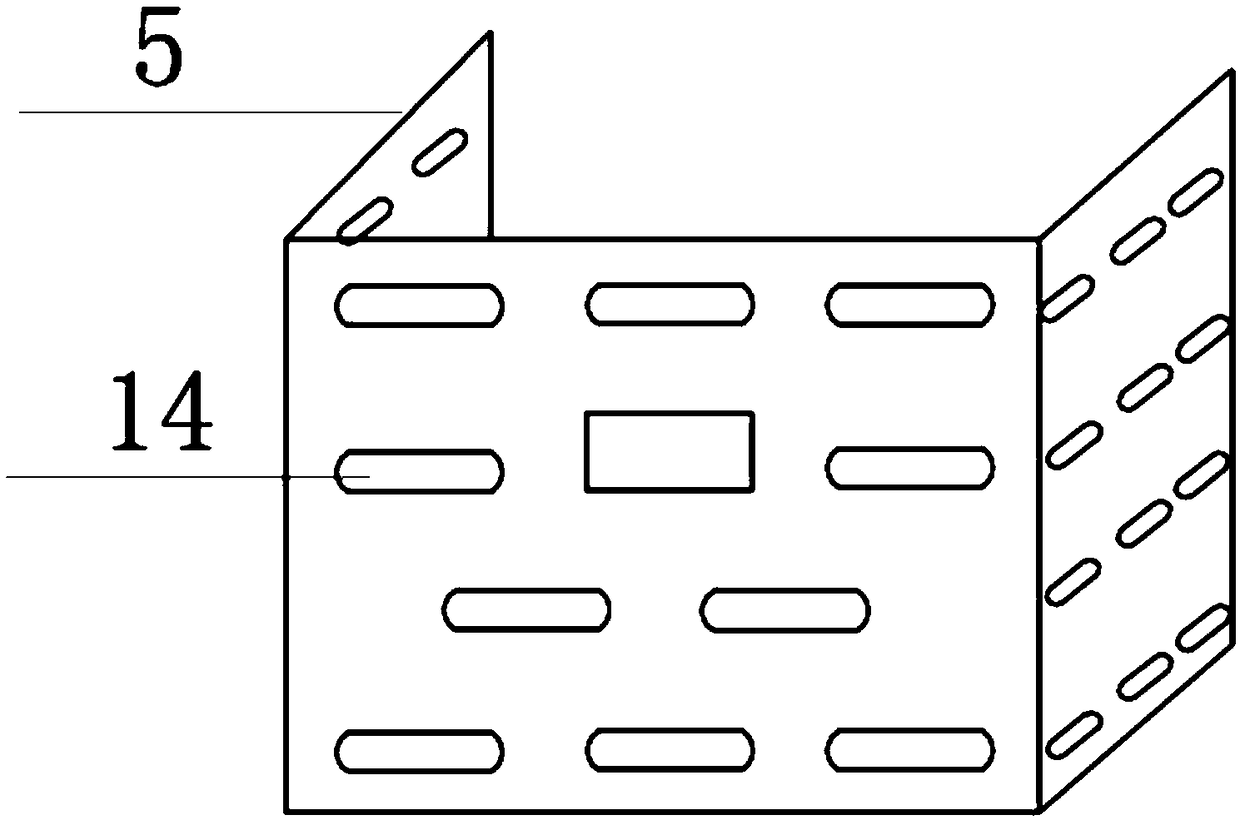

[0017] Example 1: A Z-shaped tempering box firewood energy-saving furnace, the energy-saving furnace body 1 is composed of a furnace panel 2, a furnace surface hole nesting cover 3, a furnace surface connecting seat 4, a furnace heat transfer sleeve 5, and a Z-shaped tempering box 6 , charging box 7, furnace 8, ash box handle 9, oven 10, smoke exhaust pipe seat 11, movable flue box 12, push-pull furnace bridge 13, furnace cover heat transfer hole 14, furnace furnace vent 15, tempering The flue connection 16, the flue ash storage box 17, the ash storage box 18, the connection seat connection port 19 and the furnace base 20 are composed. The energy-saving furnace body 1 is Z-shaped. There is a furnace surface nesting cover 3 on the top, a furnace surface connection seat 4 is provided under the furnace surface hole nesting cover 3, a Z-shaped tempering box 6 is provided below the furnace surface connection seat 4, and a furnace surface is provided below the Z-shaped tempering box ...

Embodiment 2

[0018] Example 2: A Z-shaped tempering box firewood energy-saving furnace, the energy-saving furnace body 1 is composed of a furnace panel 2, a furnace surface hole nesting cover 3, a furnace surface connecting seat 4, a furnace heat transfer sleeve 5, and a Z-shaped tempering box 6 , charging box 7, furnace 8, ash box handle 9, oven 10, smoke exhaust pipe seat 11, movable flue box 12, push-pull furnace bridge 13, furnace cover heat transfer hole 14, furnace furnace vent 15, tempering The flue connection 16, the flue ash storage box 17, the ash storage box 18, the connection seat connection port 19 and the furnace base 20 are composed. The energy-saving furnace body 1 is Z-shaped. There is a furnace surface nesting cover 3 on the top, a furnace surface connection seat 4 is provided under the furnace surface hole nesting cover 3, a Z-shaped tempering box 6 is provided below the furnace surface connection seat 4, and a furnace surface is provided below the Z-shaped tempering box ...

Embodiment 3

[0019] Example 3: A zigzag tempering box firewood energy-saving furnace, the energy-saving furnace body 1 consists of a furnace panel 2, a furnace surface nesting cover 3, a furnace surface connecting seat 4, a furnace heat transfer sleeve 5, and a zigzag tempering box 6 , charging box 7, furnace 8, ash box handle 9, oven 10, smoke exhaust pipe seat 11, movable flue box 12, push-pull furnace bridge 13, furnace cover heat transfer hole 14, furnace furnace vent 15, tempering The flue connection 16, the flue ash storage box 17, the ash storage box 18, the connection seat connection port 19 and the furnace base 20 are composed. The energy-saving furnace body 1 is Z-shaped. There is a furnace surface nesting cover 3 on the top, a furnace surface connection seat 4 is provided under the furnace surface hole nesting cover 3, a Z-shaped tempering box 6 is provided below the furnace surface connection seat 4, and a furnace surface is provided below the Z-shaped tempering box 6. Gall 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com