Tea baking stove with fuel gas replacing charcoal

A gas stove and gas technology, applied in drying, drying machines, burners, etc., can solve the problems that it takes a long time for the fire temperature to reach the baking temperature, uneven color of Lu'an melon slices, and poor baking effect. Achieve the effect of reducing the amount of felling, rich taste and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

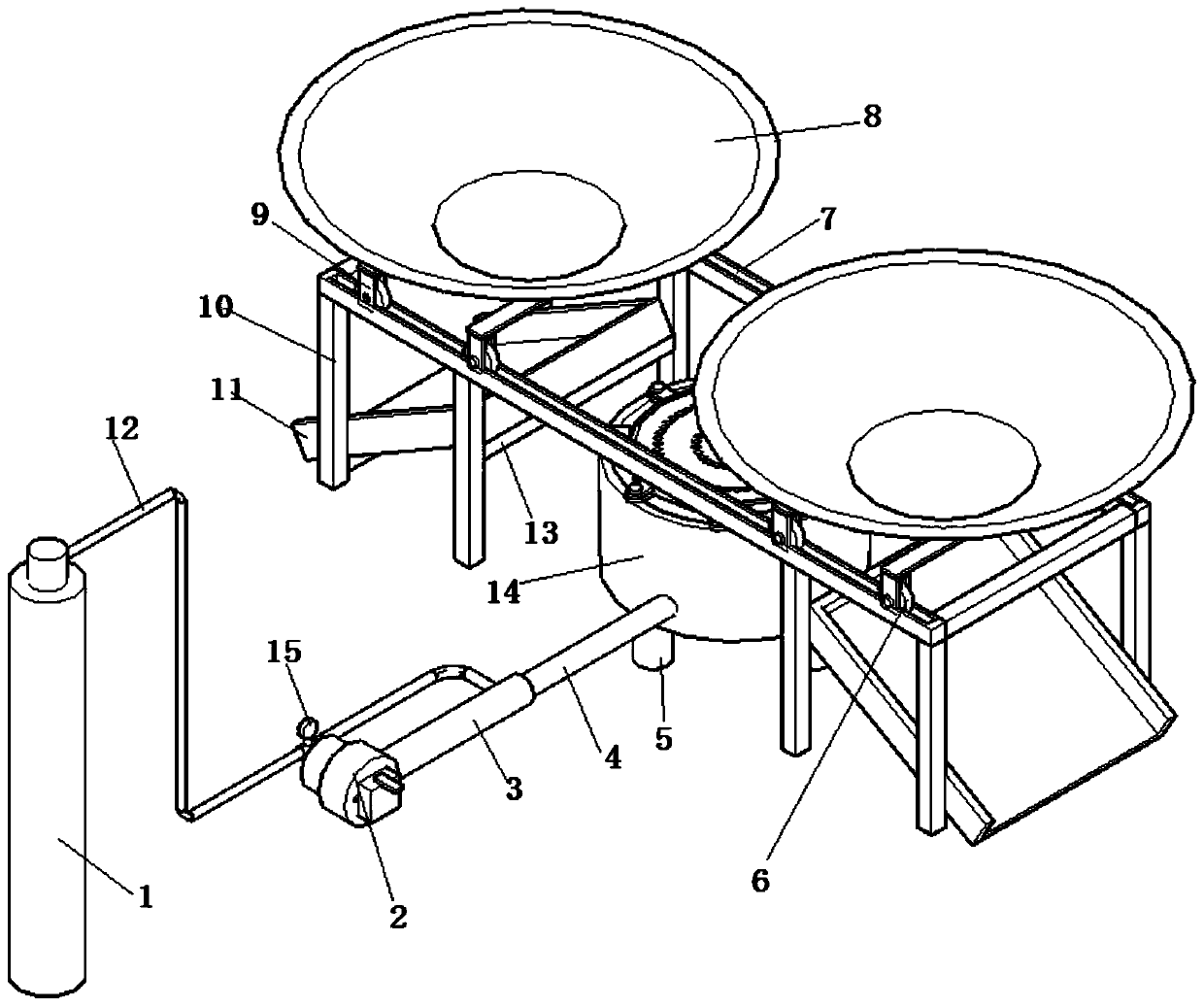

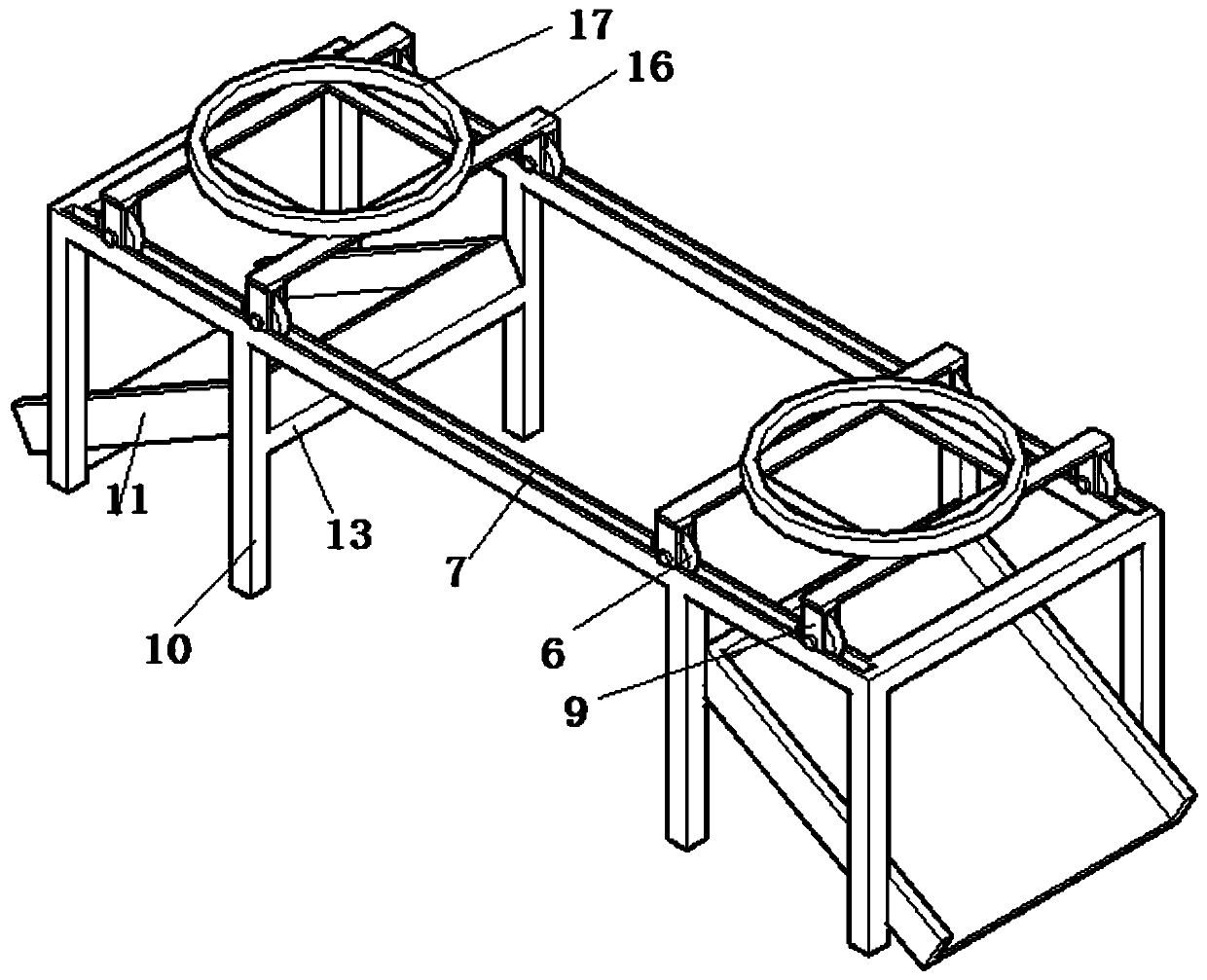

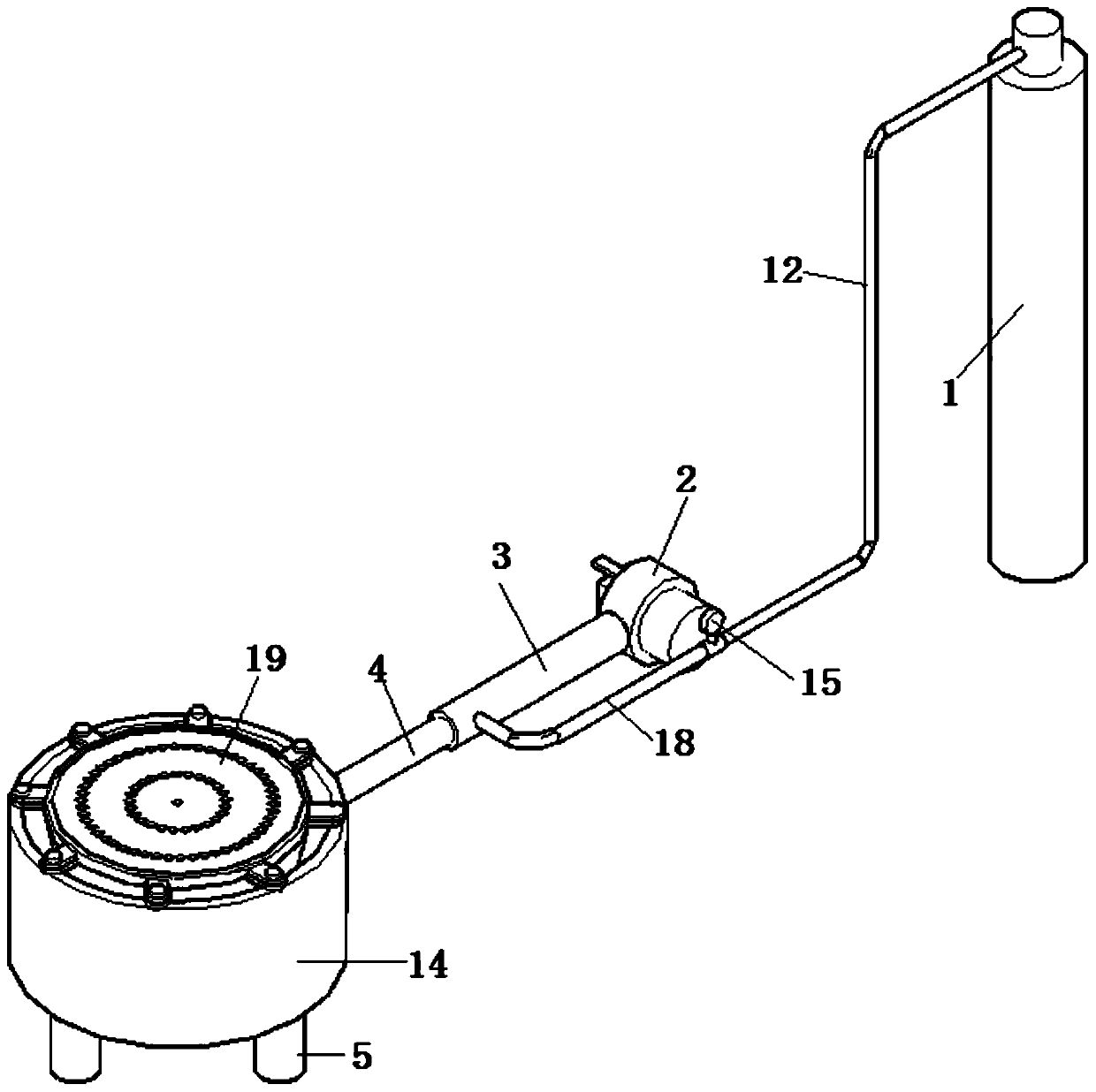

[0020] Such as Figures 1 to 5 As shown, this embodiment provides a tea baking stove with gas instead of charcoal. For the material guide assembly below, a tea basket is placed on the top of the sliding frame. A gas stove on the ground is arranged between the two guide assemblies. The gas stove is connected to a gas stove with a valve through a gas supply pipeline. The supply bottle, the gas supply pipeline includes a main pipeline connected with the gas stove, the main pipeline is connected with a blower through a ventilation pipeline, and the ventilation pipeline is connected with a soft air pipe through a bypass pipe with a pressure gauge. The flexible air tube is connected to the gas supply bottle.

[0021] Further, the sliding frame include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com