Dewatering and drying device for textile cloth

A technology for dehydrating and drying cloth, applied in drying, drying machines, heating devices, etc., can solve the problems of simple structure, single function, low drying efficiency, laborious and laborious, etc., to achieve simple structure, improve efficiency, and eliminate wrinkles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

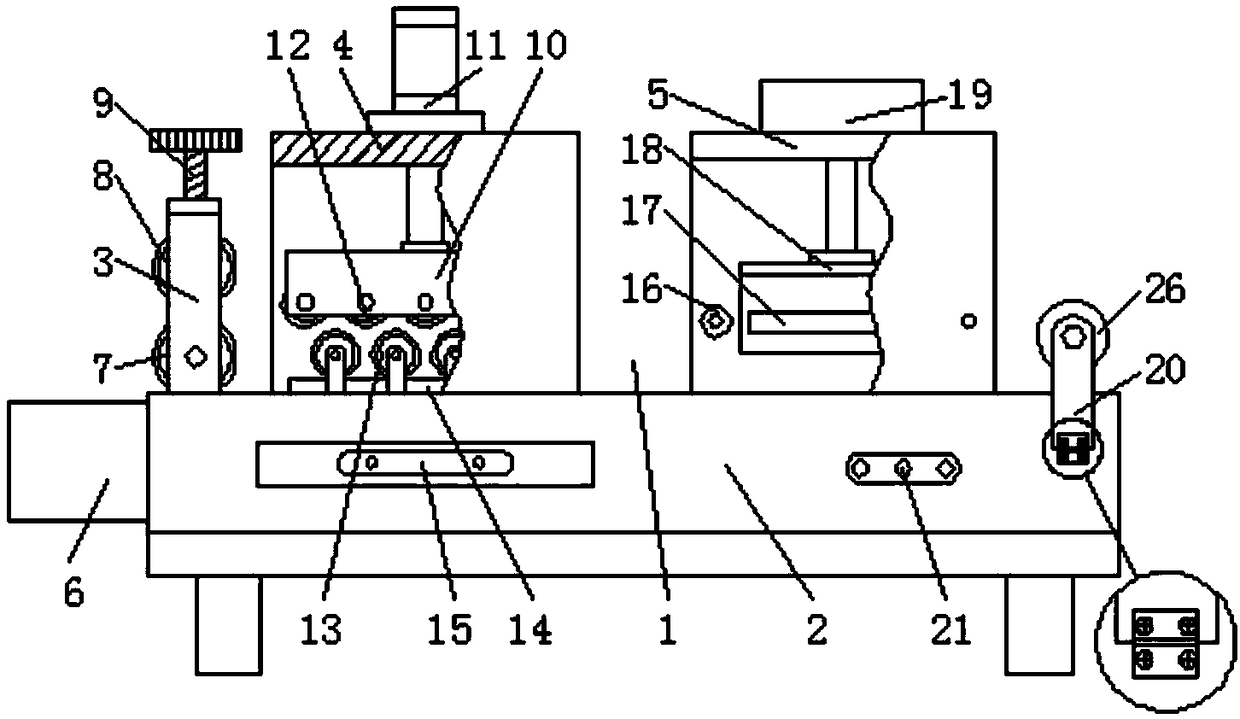

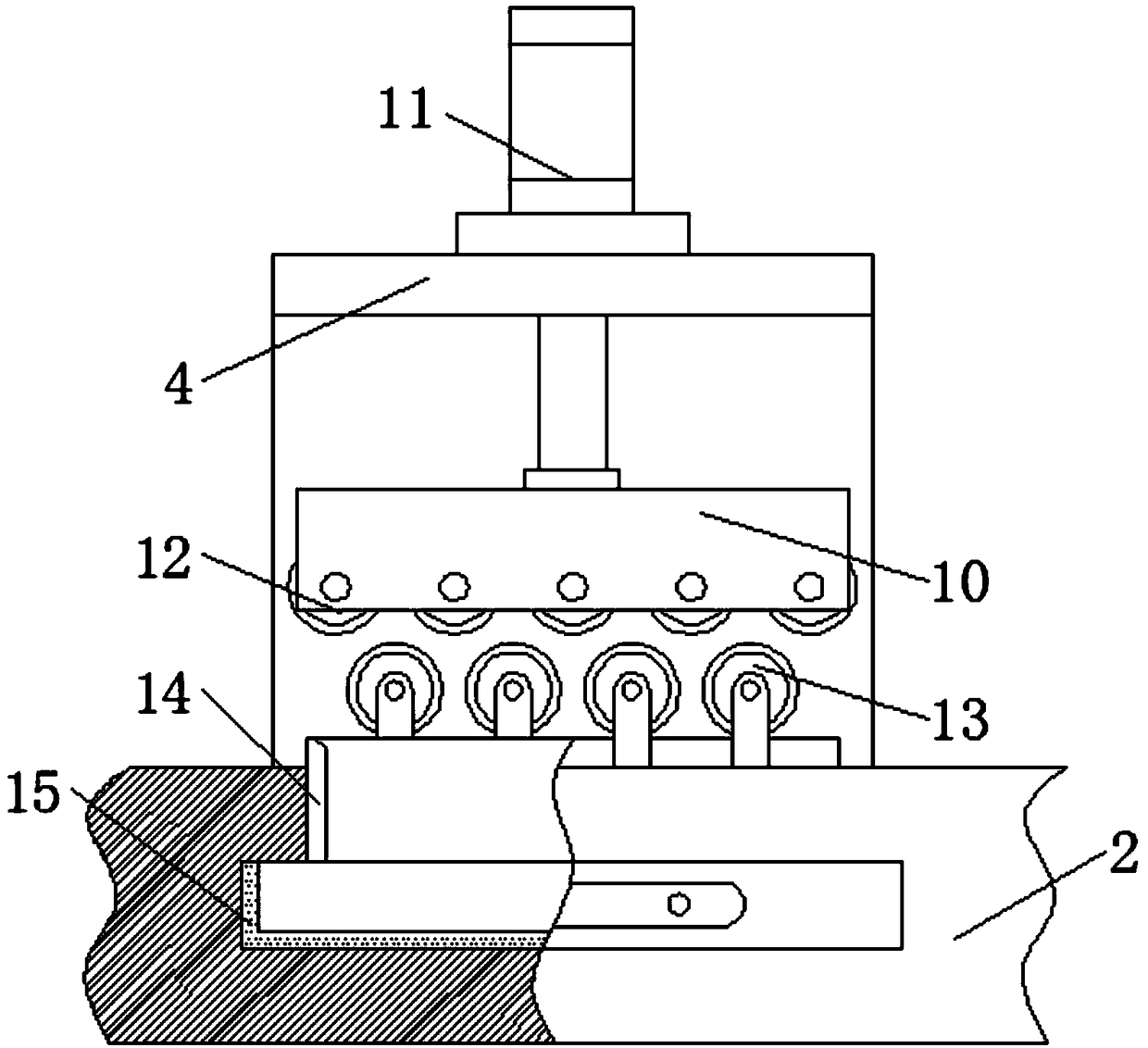

[0024] Embodiment one, with reference to Figure 1-5 , a dehydration and drying device for textile cloth, comprising a dehydration and drying device body 1 and a drying box 5, the bottom of the dehydration and drying device body 1 is provided with a workbench 2, and one side of the workbench 2 is bolted to place The box 6 and the top of the workbench 2 are symmetrically welded with a dehydration box 4 and a drying box 5. The interior of the dehydration box 4 is provided with a lifting plate 10, and the top of the dehydration box 4 is fixedly connected with a cylinder 11 used in conjunction with the lifting plate 10. The lifting plate The bottom of 10 is uniformly rotated and connected with a plurality of first dewatering rollers 12, and the bottom of dewatering box 4 is evenly rotated and connected with a plurality of second dewatering rollers 13. The inside of workbench 2 is slidingly embedded with a drain pan 15 used in conjunction with dewatering box 4. 4. The water guide p...

Embodiment 2

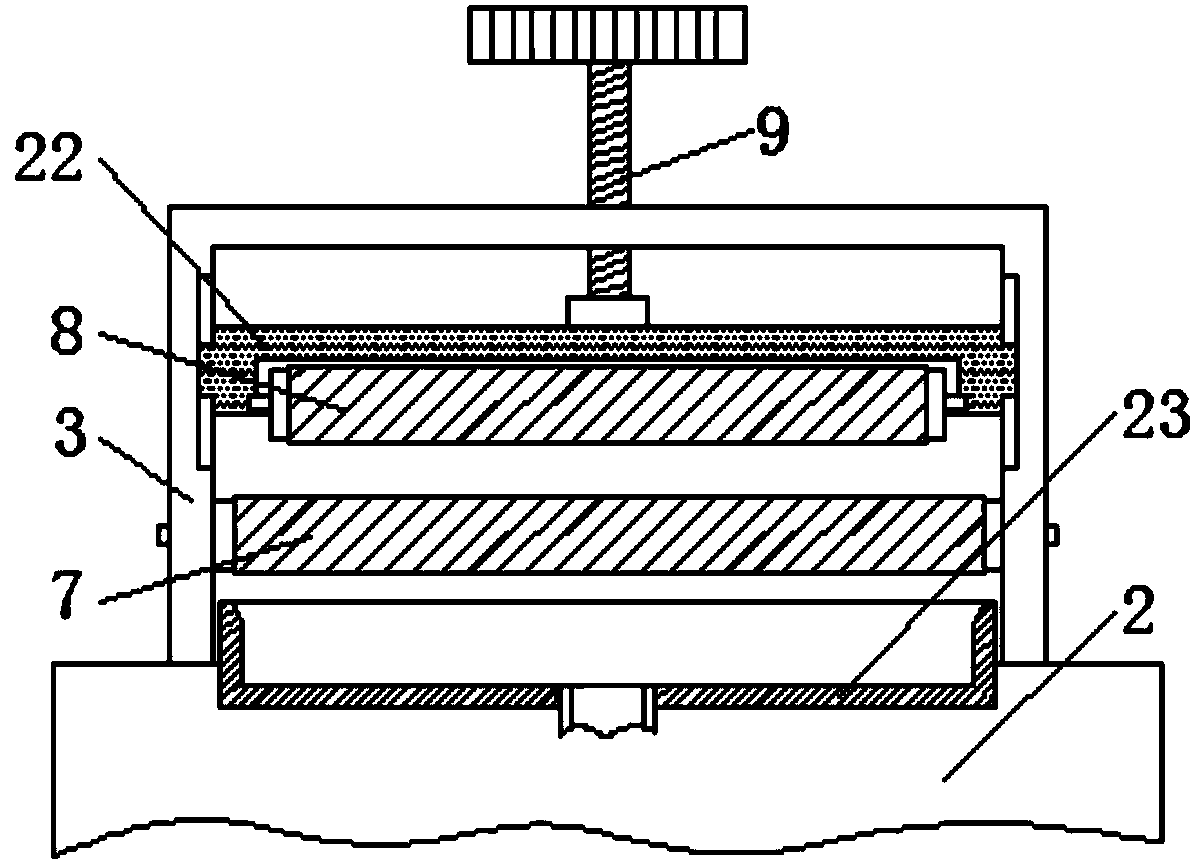

[0025] Embodiment two, refer to figure 1 and figure 2 , the top of the workbench 2 is located on one side of the dehydration box 4 and is welded with a fixed bracket 3, the inside of the fixed bracket 3 is connected with the first squeeze roller 7 through the rotation of the rotating shaft, and the top of the workbench 2 is located under the fixed bracket 3. The water receiving box 23, the water receiving box 23 communicates with the drain pan 15 through a conduit, the inside of the fixed bracket 3 is located above the first squeeze roller 7 and is slidably connected with a slide plate 22, and the bottom of the slide plate 22 is connected with a second squeeze through a rotating shaft. The top of the roller 8 and the slide plate 22 is connected with a screw 9 that runs through the fixed bracket 3. The screw 9 can be rotated to adjust the height of the slide plate 22 in the fixed support 3, so that the height of the slide plate 22 can be adjusted according to the thickness of ...

Embodiment 3

[0026] Embodiment three, refer to figure 1 and Figure 4 , the inside of the drying box 5 is fixedly connected with an air supply pan 18 above the drying plate 17, and the top bolt of the drying box 5 is fixedly connected with a fan body 19 used in conjunction with the air supply pan 18, and the fan body 19 passes through the air supply pipe. 24 communicates with the air supply disc 18, the cross section of the air supply disc 18 is an inverted C-shaped structure, the wind that can be sent into the fan body 19 is circular and evenly sent to the textile cloth in the drying box 5, and the upper drying plate 17 is matched. The textile cloth entering the inside of the drying box 5 can be dried rapidly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com