Cleaning equipment and semiconductor wafer cleaning equipment

A cleaning device and megasonic cleaning technology, which are applied in semiconductor/solid-state device manufacturing, cleaning methods and tools, cleaning methods using liquids, etc., can solve the problems of wafer center structure damage, incomplete cleaning, and low energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

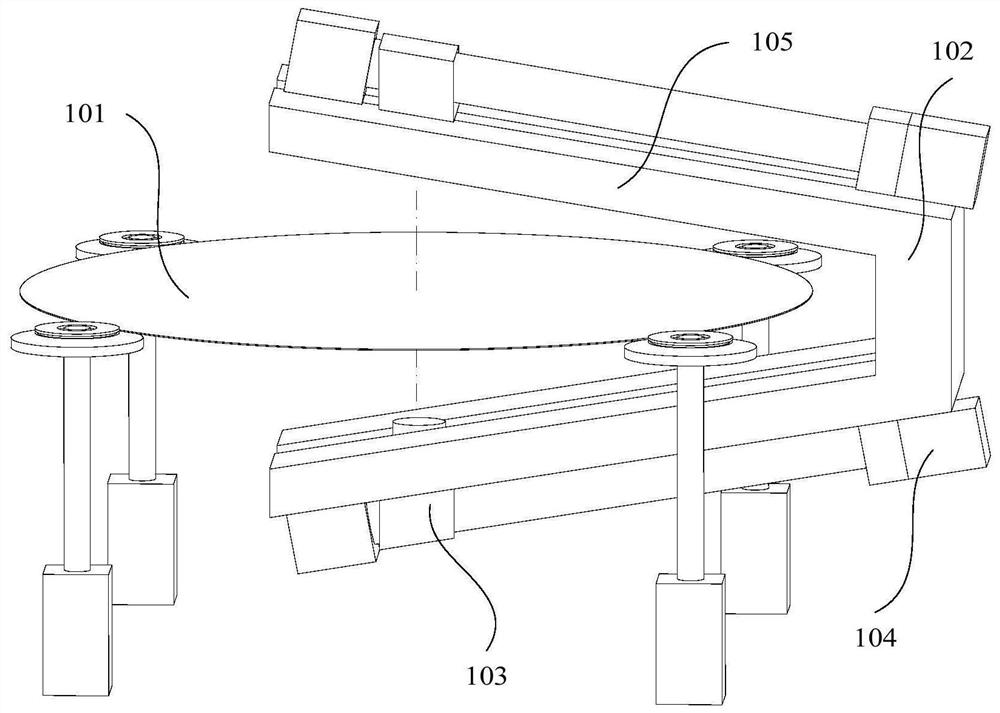

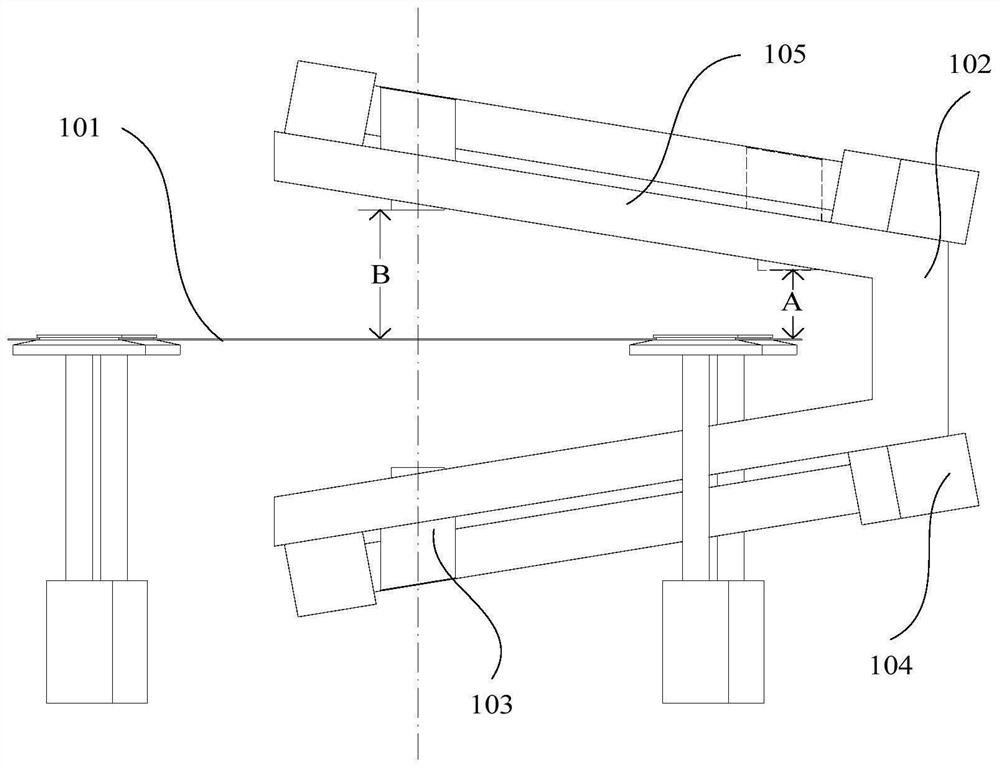

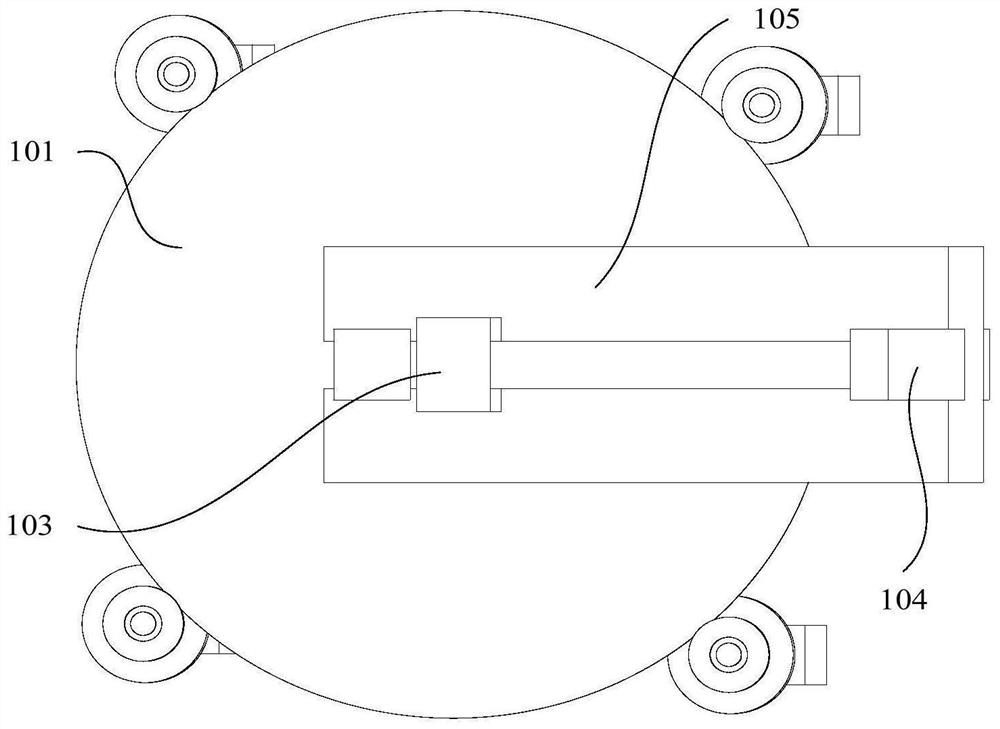

[0032] see Figure 1 to Figure 3 As shown, among them, figure 1 The cleaning device provided for Embodiment 1 of the present application is used to clean the rotating object 101 to be cleaned, including a support frame 102, a megasonic cleaning assembly 103 and a driving device 104; the support frame 102 is provided with a support arm 105, and the megasonic cleaning assembly 103 is located on the support arm 105, and the driving device 104 is used to drive the megasonic cleaning assembly 103 to reciprocate along the length direction of the support arm 105; the megasonic cleaning assembly 103 is used to clean the surface of the object to be cleaned 101; the length direction of the support arm 105 Set at an angle with the surface of the object to be cleaned 101, the vertical distance between the starting point of the movement of the megasonic cleaning assembly 103 and the surface of the object to be cleaned 101 is smaller than the distance between the end point of the movement o...

Embodiment 2

[0043] The cleaning device in the second embodiment is an improvement on the basis of the above embodiment. The technical content disclosed in the above embodiment will not be described repeatedly, and the content disclosed in the above embodiment also belongs to the content disclosed in the second embodiment.

[0044] see Figure 4 As shown, in the optional scheme of this embodiment, the megasonic cleaning assembly 103 includes a megasonic cleaning nozzle 107 and a liquid inlet pipe 108, and the liquid inlet pipe 108 is communicated with the megasonic cleaning nozzle 107, and the liquid inlet pipe 108 is used for cleaning The liquid is transported to the megasonic cleaning nozzle 107.

[0045] In this embodiment, the megasonic cleaning assembly 103 includes a megasonic cleaning nozzle 107 and a liquid inlet pipe 108, and the liquid inlet pipe 108 can transport the cleaning liquid to the megasonic cleaning nozzle 107, so that the sound waves can be combined with the chemical r...

Embodiment 3

[0054] Embodiment 3 of the present application provides a semiconductor wafer cleaning device, which includes the cleaning device described in any of the above embodiments, and thus has all the beneficial technical effects of the cleaning device described in any of the above embodiments. Here, no Let me repeat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com