Electroconductive glove leather and production method thereof

A technology of glove leather and conductive surface, which is applied in the field of synthetic leather, can solve the problems of poor three-dimensional effect and low surface brightness of finished products, and achieve the effects of soft hand feeling, time saving and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

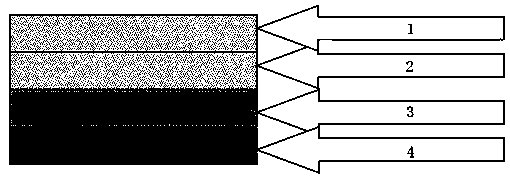

Image

Examples

Embodiment 1

[0033] Embodiment 1, a kind of production method of conductive glove leather, comprises the steps:

[0034] (1) Wet mixing ingredients:

[0035] a. Add 5 kg of dimethylformamide and 0.5 kg of color paste and stir at high speed for 60 minutes, filter for later use, and record it as material a;

[0036] b. Stir 40kg of dimethylformamide and 20kg of wood flour for 30 minutes, let it stand for 20 minutes, and stir it with material a until it is evenly used, and record it as material b;

[0037] c. Add 100kg of polyurethane wet-process resin to material a and material b, stir for 20 minutes, defoam, filter and seal for use, and record it as material c;

[0038] (2) Wet process bass production: apply scratching material on the prepared elastic base cloth, adjust the tension, solidify in 18-30% dimethylformamide aqueous solution, wash with water, and dry to obtain a wet For Fabes, the vehicle speed is controlled at 10m / min;

[0039] (3) Dry mixing ingredients:

[0040] 3.1): Mix ...

Embodiment 2

[0046] Embodiment 2, a kind of production method of conductive glove leather, comprises the steps:

[0047] (1) Wet mixing ingredients:

[0048] a. Stir 8 kg of dimethylformamide and 1 kg of color paste at high speed for 75 minutes, filter for later use, and record it as material a;

[0049] b. Add 80kg of dimethylformamide and 25kg of wood flour and stir for 30 minutes. After standing for 30 minutes, stir with material a evenly for later use, and record it as material b;

[0050] c. Add 100kg of polyurethane wet-process resin to material a and material b and stir for 30 minutes, then defoam and filter and seal for use, which is recorded as material c;

[0051] (2) Wet process bass production: apply scraping material on the prepared elastic base cloth, adjust the tension, solidify in 25% dimethylformamide aqueous solution, wash and dry to obtain a wet process bass , the vehicle speed is controlled at 15m / min;

[0052] (3) Dry mixing ingredients:

[0053] 3.1): Mix the poly...

Embodiment 3

[0059] Embodiment 3, a kind of production method of conductive glove leather, comprises the steps:

[0060] (1) Wet mixing ingredients:

[0061] a. Stir 10kg of dimethylformamide and 2kg of color paste at high speed for 90 minutes, filter for later use, and record it as material a;

[0062] b. Add 100kg of dimethylformamide and 30kg of wood flour and stir for 30 minutes, let it stand for 45 minutes and then mix it with material a evenly for later use, and record it as material b;

[0063] c. Add 100kg of polyurethane wet-process resin to material a and material b, stir for 40 minutes, then defoam, filter and seal for use, and record it as material c;

[0064] (2) Wet process bass production: apply scraping material on the prepared elastic base cloth, adjust the tension, solidify in 18-30% dimethylformamide aqueous solution, wash with water, and dry to obtain a wet For Fabes, the vehicle speed is controlled at 20m / min;

[0065] (3) Dry mixing ingredients:

[0066] 3.1): Mix t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com