Dust collector

A technology for vacuum cleaners and suction pipes, which is applied in the direction of vacuum cleaners, suction nozzles, suction hoses, etc., which can solve the problems of poor filtration efficiency and filtration effect, and achieve simple and practical structure, increased dust suction wind power, and convenient assembly and disassembly quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

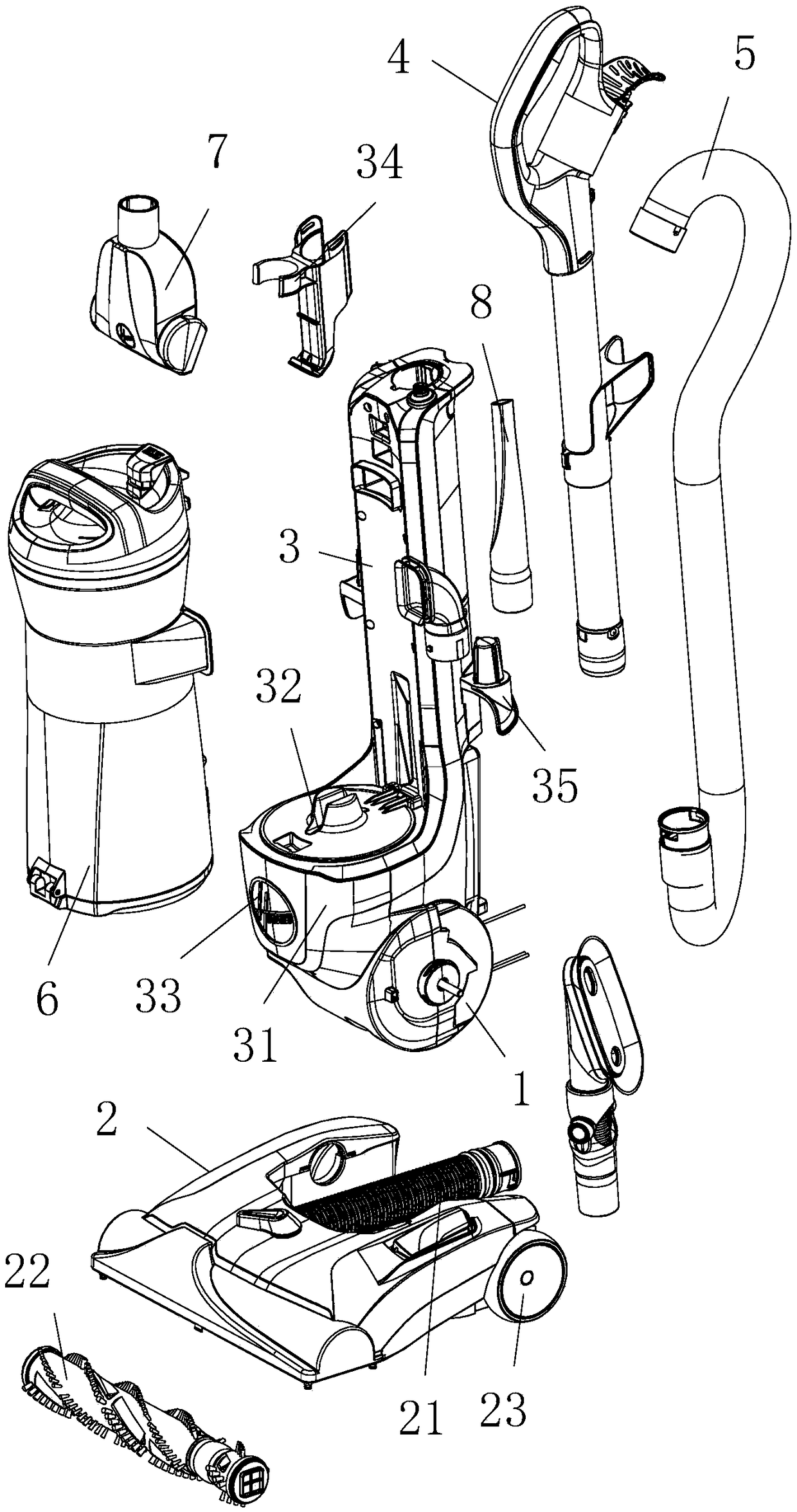

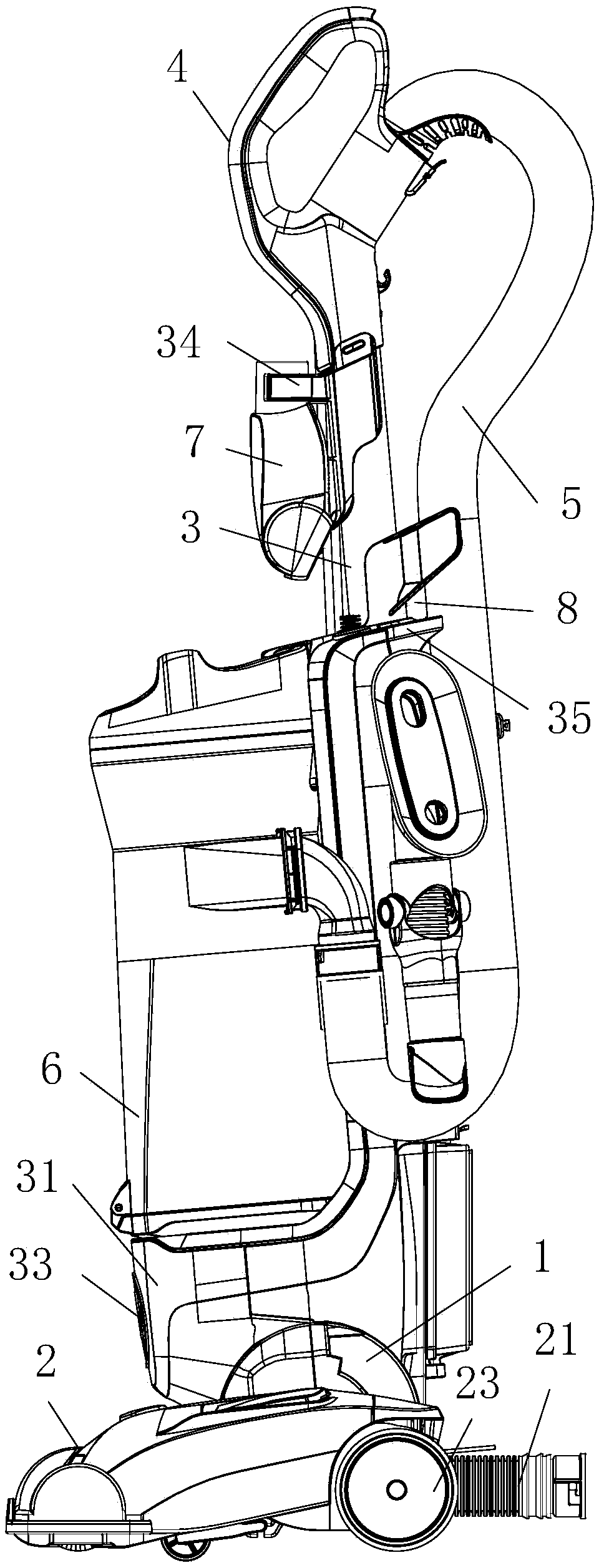

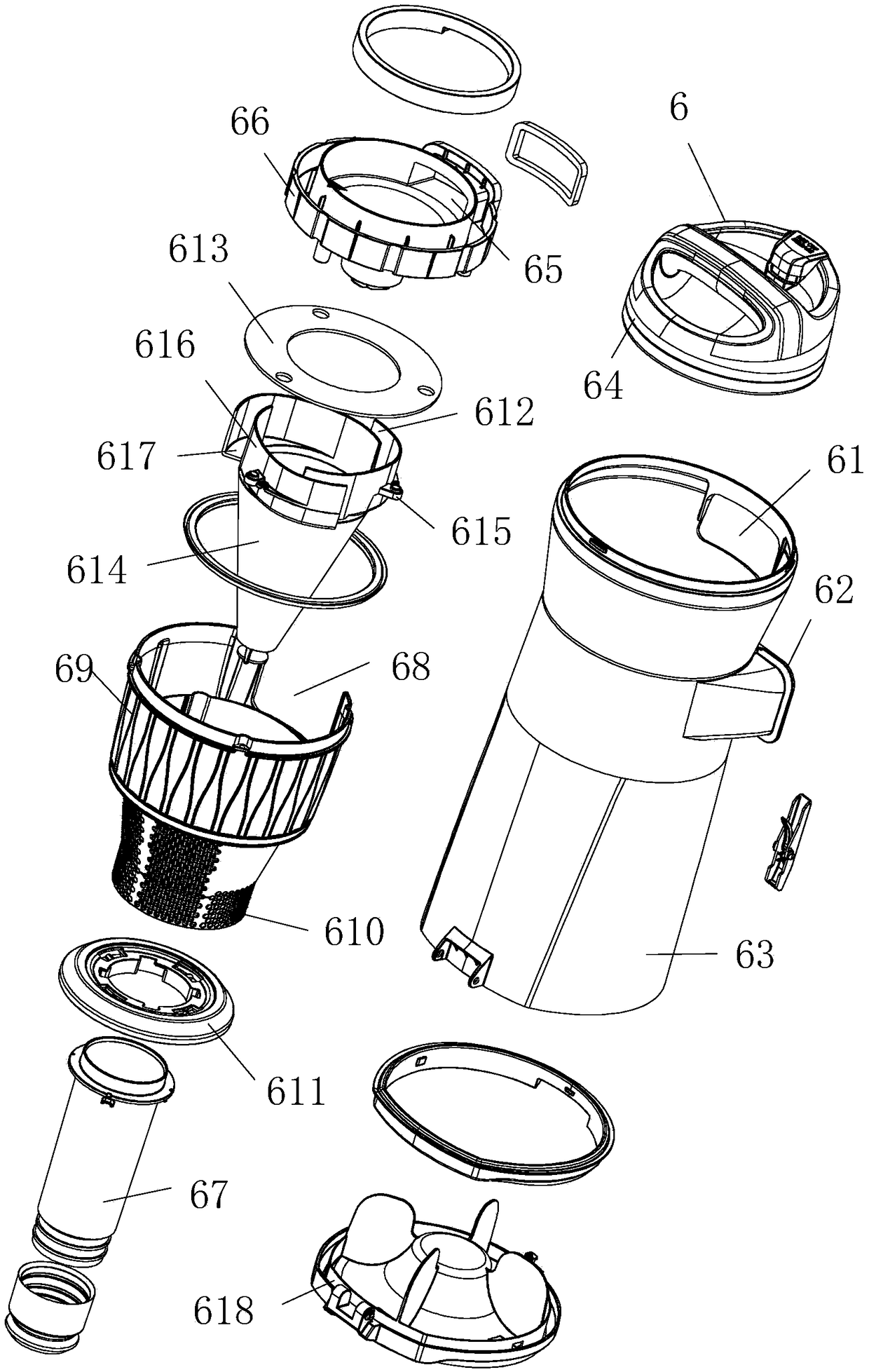

[0023] as attached figure 1 to attach Figure 6Shown: a vacuum cleaner, comprising: a ground mopping device 2 provided with an air extraction pipe 21, a rolling brush 22 and a roller 23, an air extraction fan 1 connected to the upper end of the floor mopping device 2, and a suction fan 1 connected to the lower end of the mop device 2; The fuselage 3 of the dust collector 31 is located on one side of the fuselage 3 and is provided with a dust suction pipe 5 with a handle 4, several dust suction heads, and a dust cup filter device 6 located at the upper end of the dust collector 31; The filtering device 6 comprises: a casing 63 with a suction port 61 communicated with the suction end of the suction fan 1 and a suction port 62 located at the lower side of the suction port 61 and connected with the other end of the suction pipe 5 around the side, and the housing 63 The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com