Electro-hydraulic composite braking ABS control system and method based on hub motor

A technology of ABS controller and wheel hub motor, which is applied in the direction of brakes, brake transmissions, transportation and packaging, etc. It can solve problems such as fast response speed, potential safety hazards, failure of ABS system, etc., and achieve accurate and reliable acquisition of wheel speed and safety And the effect of high reliability and convenient installation and arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

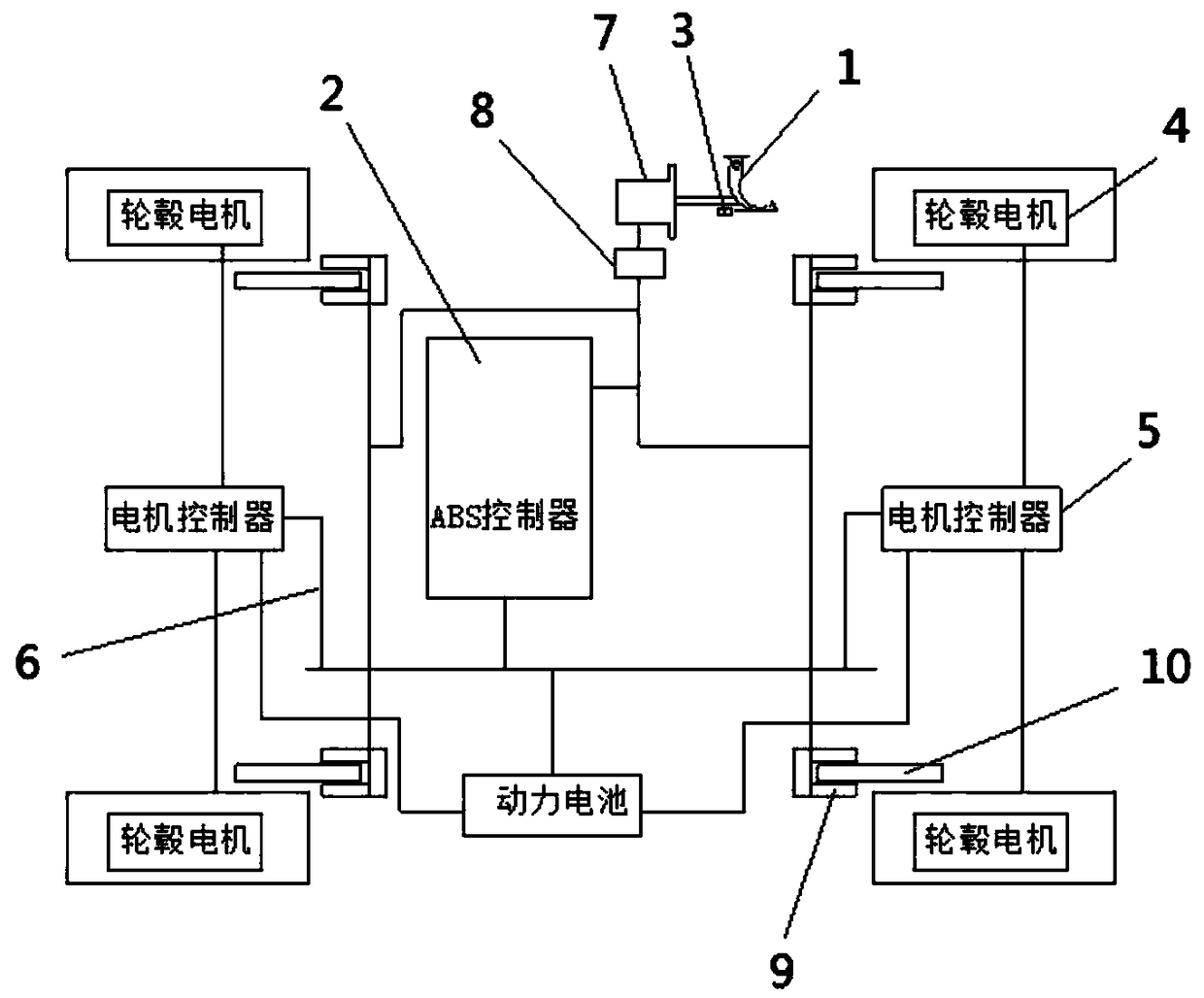

[0028]An ABS control system based on an electro-hydraulic composite brake of an in-wheel motor, including a brake pedal 1, an ABS controller 2, a hydraulic brake module electrically connected to the ABS controller 2, a motor brake module, and a brake pedal sensor 3. The motor braking module includes hub motors 4 arranged on each wheel, and a motor control module electrically connected to each hub motor 4, and the motor control module communicates with the ABS controller 2 through a CAN bus 6 for The wheel speed signals of each wheel are transmitted to the ABS controller 2; the motor control module includes two motor controllers 5, and the two motor controllers 5 are installed on the front and rear of the vehicle body respectively, and the The motor controller 5 is used to control the hub motor 4 of the left front wheel and the right front wheel, and the motor controller 5 located at the rear is used to control the hub motor 4 of the left rear wheel and the right rear wheel, and...

Embodiment 2

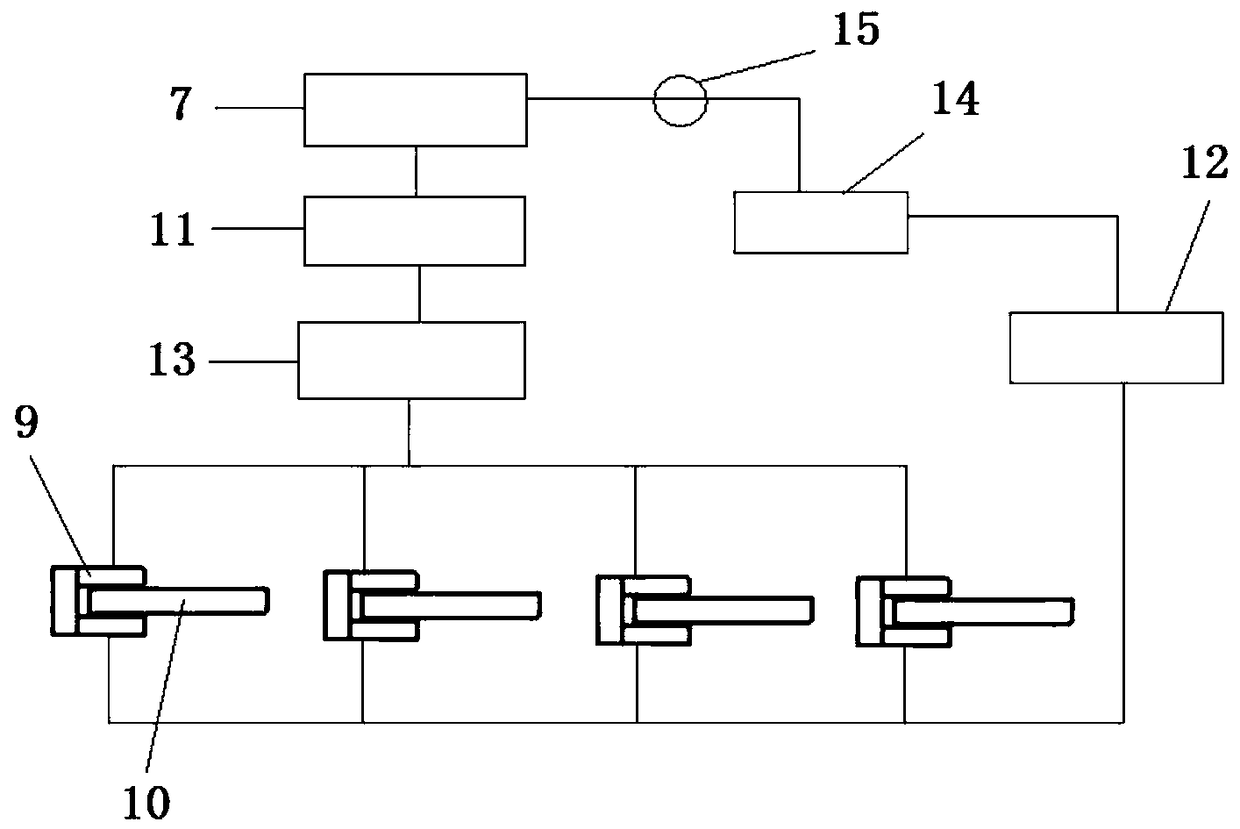

[0030] An ABS control method based on the electro-hydraulic compound braking of the hub motor, the method is based on the ABS control system of the electro-hydraulic compound braking based on the hub motor in embodiment 1, and it comprises the following steps:

[0031] (1) The ABS controller 2 detects in real time whether the brake pedal 1 is depressed through the brake pedal sensor 3?

[0032] If so, it is judged that the automobile starts to brake and enters step (2);

[0033] If not, return to step (1) to continue judging;

[0034] (2) The ABS controller 2 obtains the wheel speed signals of each wheel detected by the motor control module in real time through the CAN bus 6, and the motor controller 5 positioned at the front of the vehicle body is used to detect the wheel hub motors 4 of the left front wheel and the right front wheel. Wheel speed signal, the motor controller 5 located at the rear of the vehicle body is used to detect the wheel speed signals of the hub motors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com