Ocean engineering operating platform and operating method

A technology for operating platforms and marine engineering, which is applied in the direction of increasing the stability of ships, ships, floating buildings, etc. It can solve the problems of affecting the service life of the platform, the surface erosion of the platform body, and damaging the platform, so as to facilitate marine operations and prolong the life of the platform. The effect of service life and reduction of wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

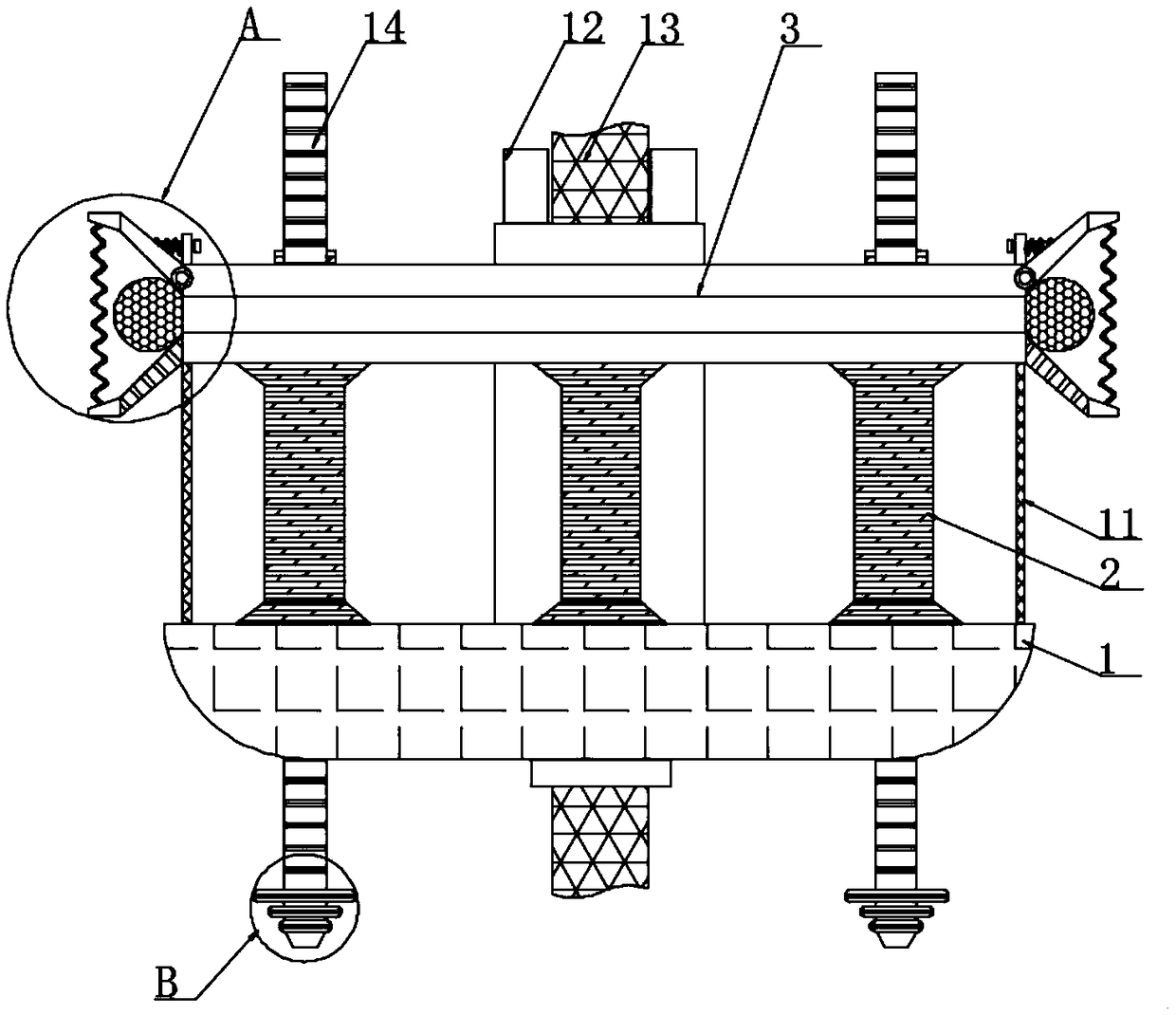

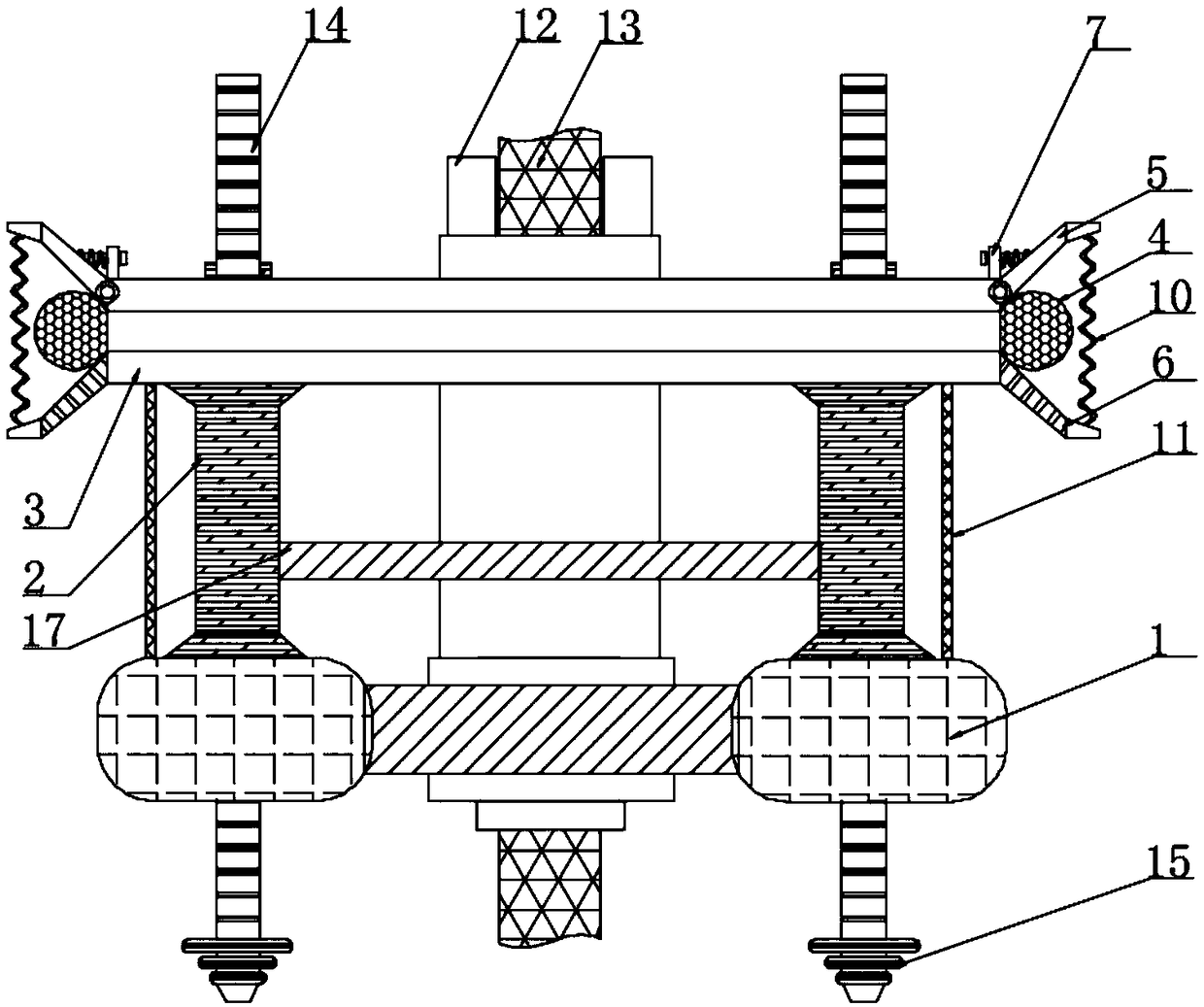

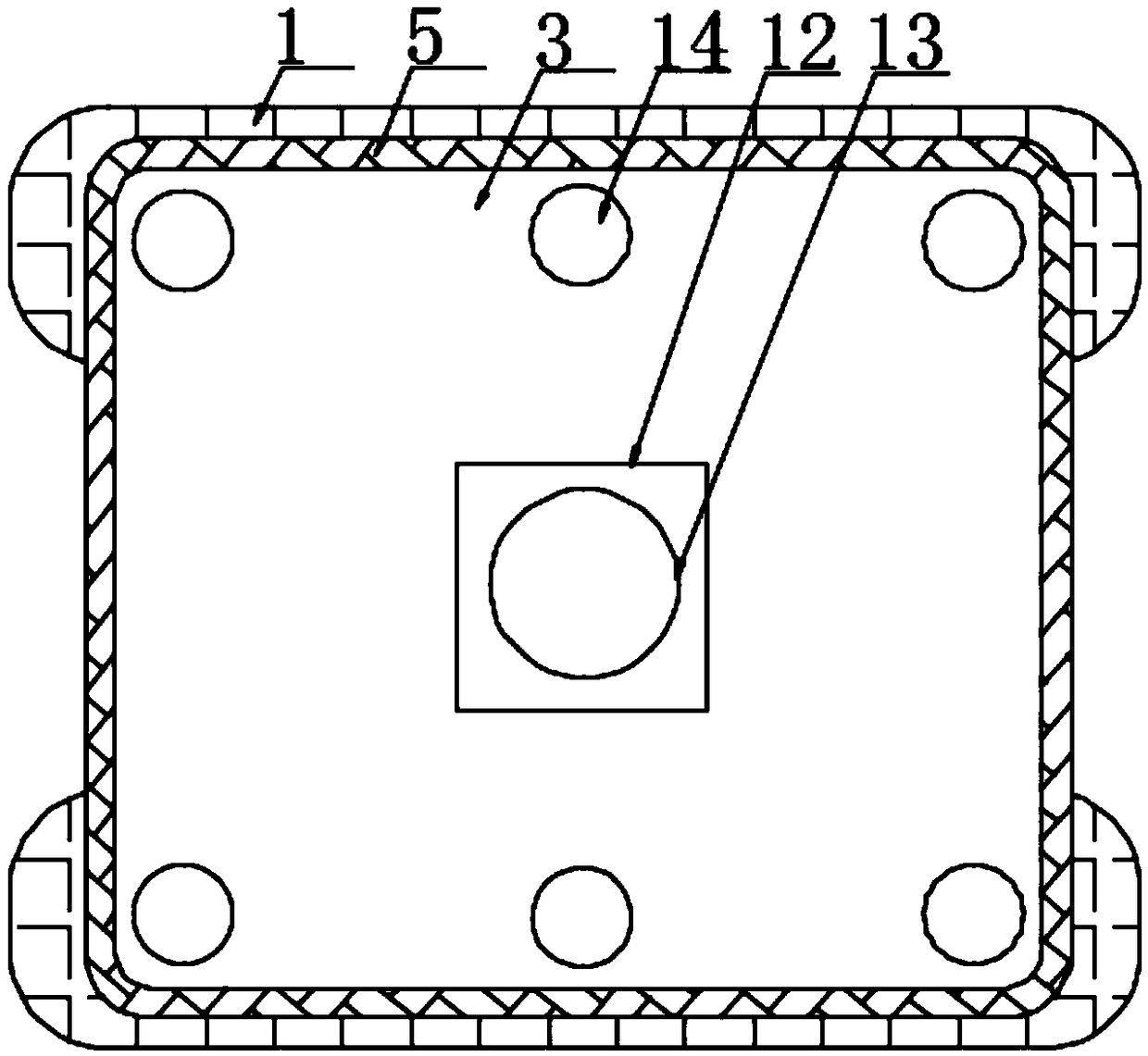

[0027] The present invention provides such Figure 1-5 A marine engineering operation platform shown includes a bottom floating body 1, a number of middle columns 2 are fixedly connected to the top of the bottom floating body 1, a platform body 3 is fixedly connected to the top of the middle column 2, and the outer side of the platform body 3 is fixedly connected to There is a buffer ball 4, the top of the buffer ball 4 is hinged with a wave avoidance plate 5, the bottom of the buffer ball 4 is fixedly connected with a splitter plate 6, and the outside of the platform body 3 is provided with a fixed block 7, and one side of the fixed block 7 runs through There is a sliding hole, and a sliding rod 8 is slidably connected in the sliding hole. One end of the sliding rod 8 is hinged with the wave avoiding plate 5. The outer side of the wave avoiding plate 5 is provided with a compression spring 9. A tension spring 10 is fixedly connected between them, and a protective net 11 is pr...

Embodiment 2

[0037] A method for operating an ocean engineering operation platform, including the ocean engineering operation platform, further comprising the following steps:

[0038] S1: set buffer ball 4 to weaken the force of ocean waves on platform body 3;

[0039] S2: Set up the wave avoiding board 5 to intercept the seawater and reduce the amount of water entering the platform body 3 by waves;

[0040] S3: The wave avoidance plate 5 is impacted to push the slide bar 8 to slide in the slide hole, compressing the compression spring 9, after the waves beat, the seawater falls on the splitter plate 6 and falls from the screen holes 18, reducing the force of the waves;

[0041] S4: Under the action of the elastic force of the compression spring 9 and the tension spring 10, the wave avoidance plate 5 returns to its original position and continues to work;

[0042] S5: The protective net 11 prevents foreign matter from hitting the middle column 2, and is used to ensure the stability of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com