Pickled pepper food bagging machine

A bagging machine and food technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of long exposure time of pickled pepper food, low bagging efficiency of pickled pepper food, shortening the shelf life of pickled pepper food, etc. Conducive to preservation and preservation, reducing bacterial infection and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below by means of specific embodiments:

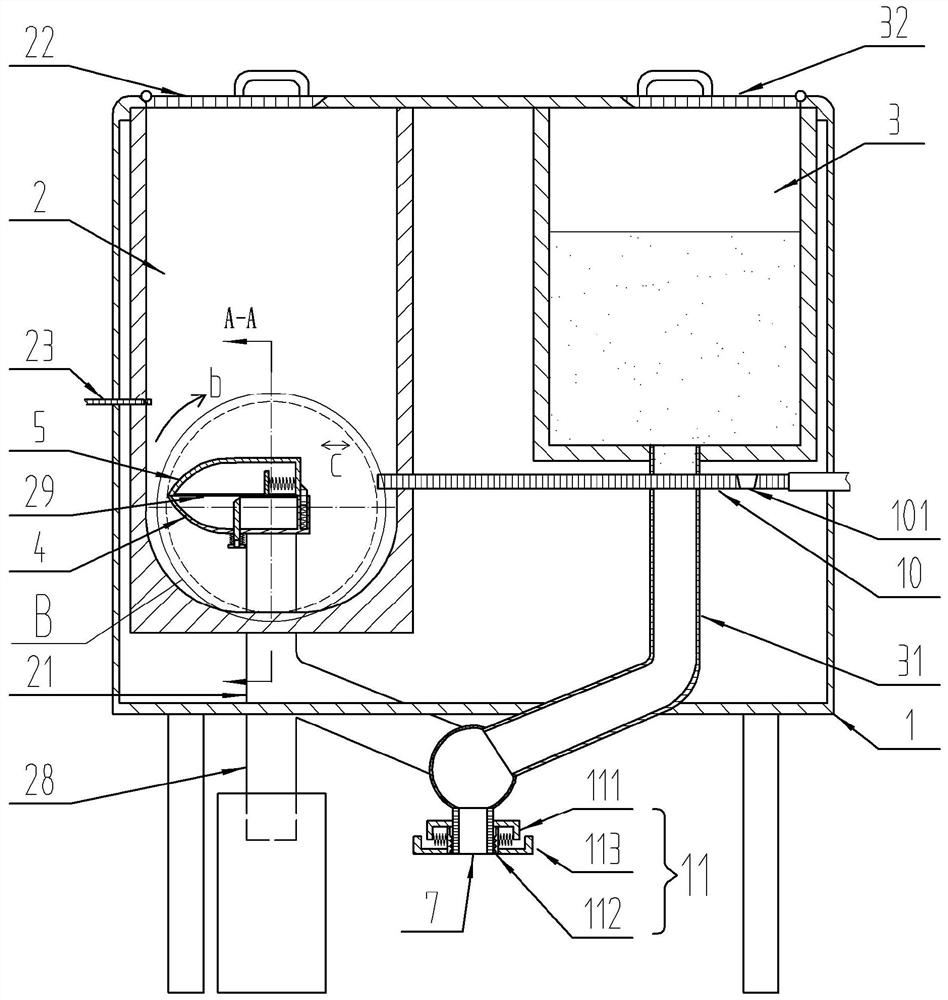

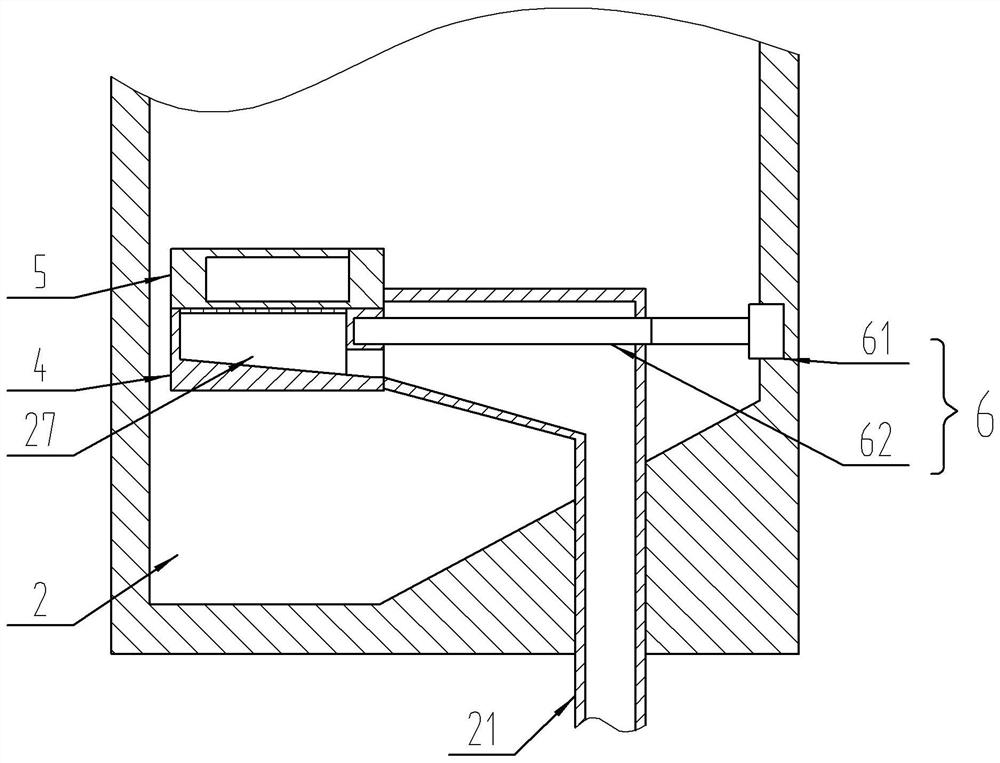

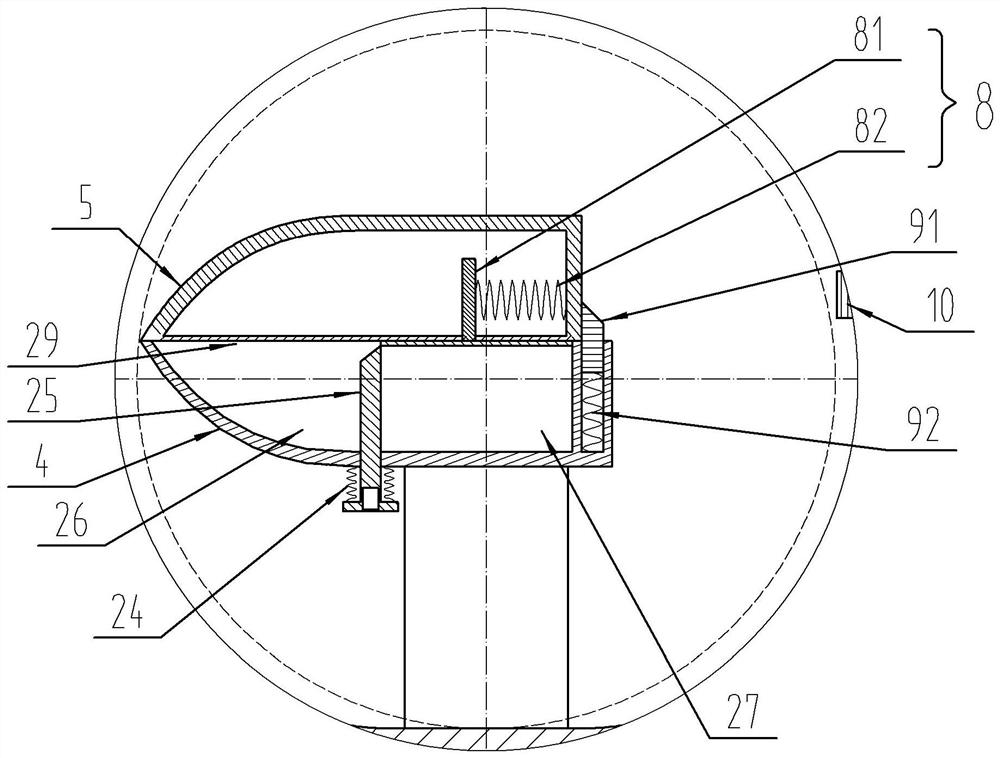

[0029] The reference signs in the accompanying drawings of the description include: box body 1, solid storage bin 2, solid feeding pipe 21, solid feeding cover 22, first driving rod 23, first extension spring 24, partition plate 25, container Cavity 26, material leakage cavity 27, drain pipe 28, feed port 29, liquid storage bin 3, liquid feed pipe 31, liquid feed cover 32, scoop 4, closure 5, power mechanism 6, motor 61, Drive shaft 62, discharge pipe 7, first limit member 8, first limit plate 81, second compression spring 82, second wedge block 91, third compression spring 92, second drive rod 10, leakage hole 101 , pocket clamping member 11 , support rod 111 , clamping rod 112 , handle 113 .

[0030] like figure 1 , figure 2 and image 3 As shown, the pickled pepper food bagging machine includes a casing 1, and the casing 1 is provided with a solid storage bin 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com