Production technology of crepe jacquard low elasticity fabric

A production process, low-elasticity crepe technology, applied in the direction of digging fabrics, fabrics, textiles, etc., can solve the problem of low twist, improve elasticity and toughness, feel comfortable, and improve economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

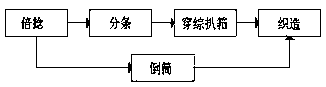

[0029] A production process of jacquard crepe low-elasticity fabric, comprising the following process steps: winding - two-for-one twisting - section warping - drafting - temperature and humidity control - weaving, wherein:

[0030] a. Winding: use the SGD168 type winding machine, set the winding weight to 1.24kg, the winding time to 245 minutes, and the curling force to be 33CN for winding;

[0031] b. Two-for-one twisting: use YB310G two-for-one twisting machine, set the spindle speed to 13000r / min, increase the expansion force beads to 0.9*3 grains, and perform two-for-one twisting with a wrap angle of 540°; The force is controlled at 7CN;

[0032] c. Segment warping: set the speed of the large drum at 250m / min, the inverted axis at 60m / min, and equip with No. 3 tension cap. The warping tension is controlled at 12g, and the inverted axis tension is controlled at 2kg. According to 770 grains*10 strips for warping;

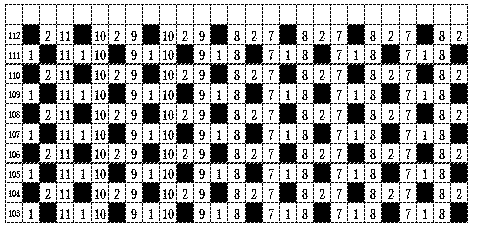

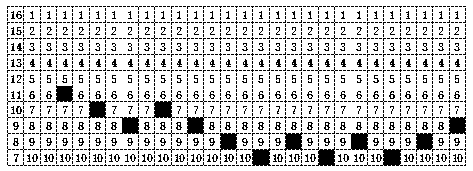

[0033] d. Heald threading: 16 pieces of healds are used, ...

Embodiment 2

[0037] A production process of jacquard crepe low-elasticity fabric, comprising the following process steps: winding - two-for-one twisting - section warping - drafting - temperature and humidity control - weaving, wherein:

[0038] a. Winding: Use the SGD168 type winding machine, set the winding weight to 1.25kg, the winding time to 245 minutes, and the curling force to be 35CN for winding;

[0039] b. Two-for-one twisting: use the YB310G two-for-one twister, set the spindle speed to 13000r / min, increase the expansion force beads to 0.9*3 grains, and perform two-for-one twisting with a wrap angle of 540°; The tension is controlled at 8CN;

[0040] c. Segment warping: set the speed of the large drum at 250m / min, the inverted axis at 60m / min, and equip with No. 3 tension cap. The warping tension is controlled at 12g, and the inverted axis tension is controlled at 2kg. According to 770 grains*10 strips for warping;

[0041] d. Heald threading: 16 pieces of healds are used, and...

Embodiment 3

[0045] A production process of jacquard crepe low-elasticity fabric, comprising the following process steps: winding - two-for-one twisting - section warping - drafting - temperature and humidity control - weaving, wherein:

[0046] a. Winding: Use the SGD168 type winding machine, set the winding weight to 1.26kg, the winding time to 245 minutes, and the curling force to be 37CN for winding;

[0047]b. Two-for-one twisting: use the YB310G two-for-one twister, set the spindle speed to 13000r / min, increase the expansion force beads to 0.9*3 grains, and perform two-for-one twisting with a wrap angle of 540°; The force is controlled at 9CN;

[0048] c. Segment warping: set the speed of the large drum at 250m / min, the inverted shaft at 60m / min, and equip with No. 3 tension cap. The warping tension is controlled at 12g, and the inverted shaft tension at 2kg. According to 770 grains*10 strips for warping;

[0049] d. Heald threading: 16 pieces of healds are used, and the healds are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com