Anti-erosion high-temperature high-pressure packer

A high-temperature, high-pressure, packer technology, which is applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc., can solve problems such as breakdown and rubber tube tearing, and achieve simple structure and large displacement Effect of construction and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

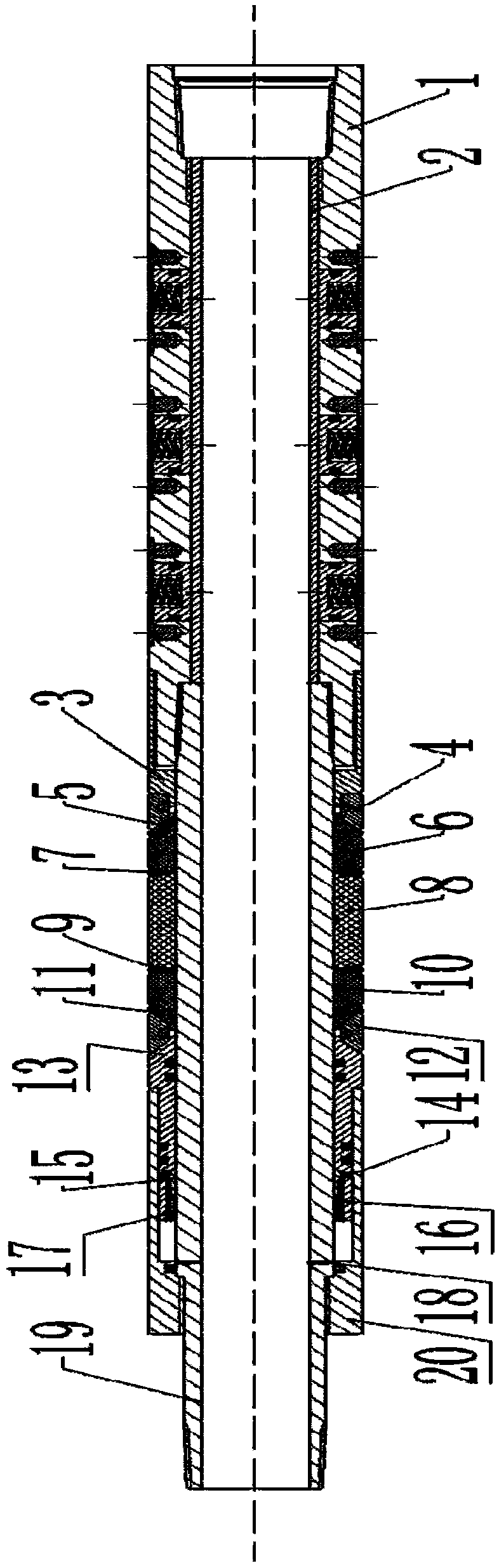

[0021] An erosion-resistant high-temperature and high-pressure packer, such as figure 1 As shown, it includes an anchoring mechanism arranged on the upper part of the central tube 19, a sealing mechanism sleeved on the central tube 19, and a seating / unsealing mechanism arranged at the bottom of the central tube 19;

[0022] The anchoring mechanism includes a hydraulic anchor 1 and an anti-scour tube 2 arranged inside the hydraulic anchor 1; the lower part of the anti-scour tube 2 presses against the top of the central tube 19;

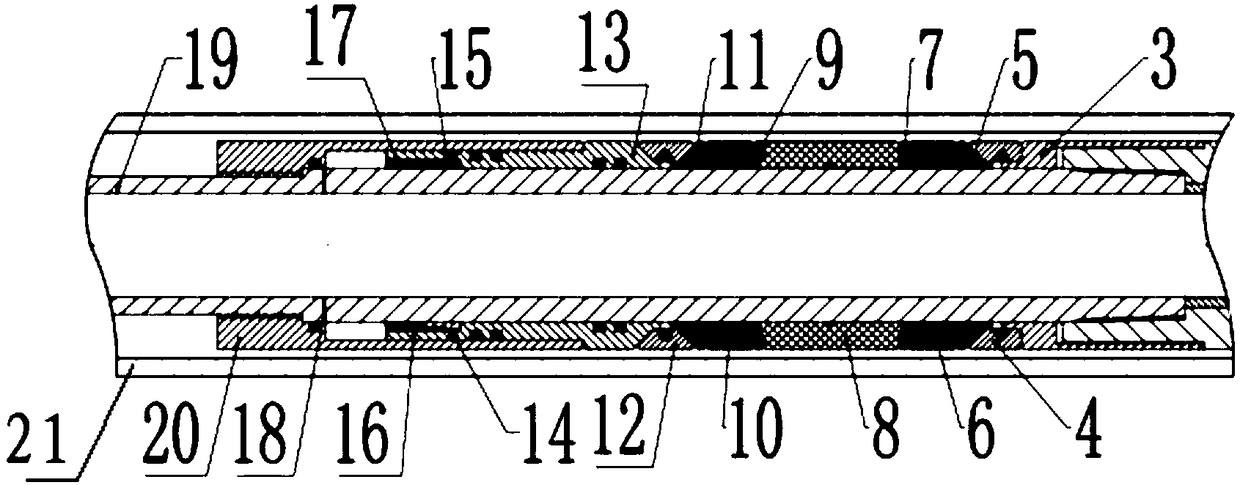

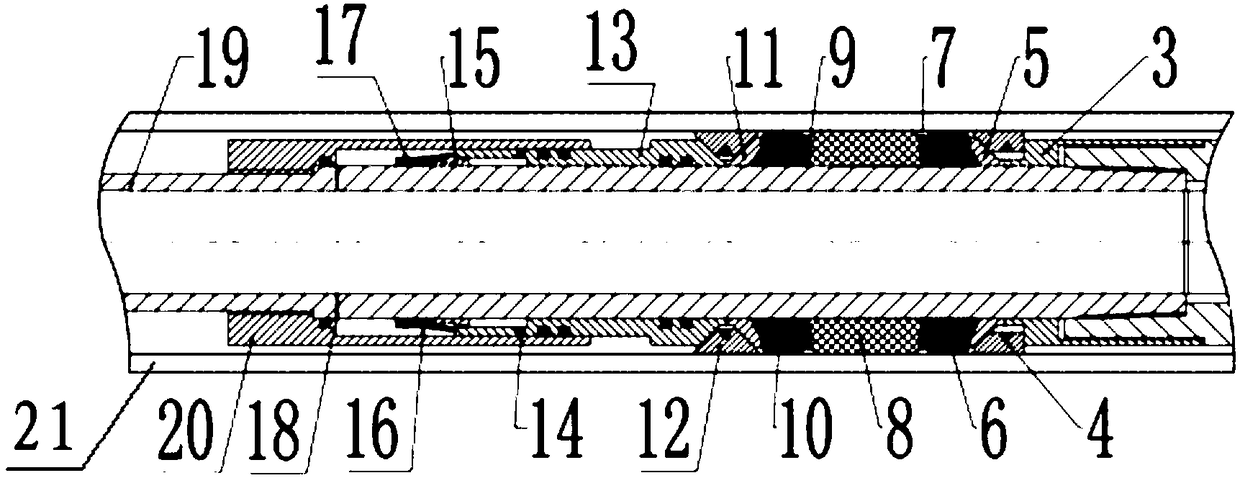

[0023] The sealing mechanism includes the rubber cartridge adjustment ring 3 and the alloy protection ring-upper 4 which is set on the center tube from top to bottom, the rubber cartridge positioning ring-upper 5, the supporting rubber cartridge-upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com