A Downhole Self-operated Forced Vortex Drainage and Gas Production Device

A technology for forced eddy current and drainage gas production. It is used in the production of fluids, earth-moving drilling, wellbore/well components, etc. It can solve the problems of limited fluid swirl intensity and swirl continuous distance, and achieve easy gas-liquid separation and fluid separation. The effect of conveying, high swirl strength, easy working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

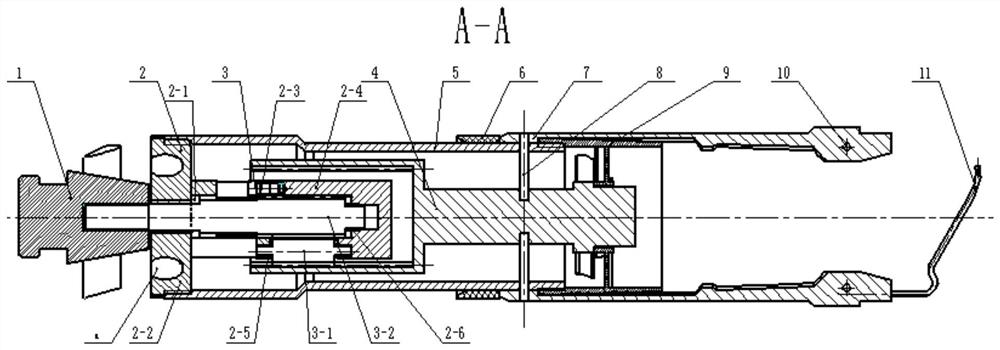

[0025] The present invention will be described in detail below with reference to the accompanying drawings.

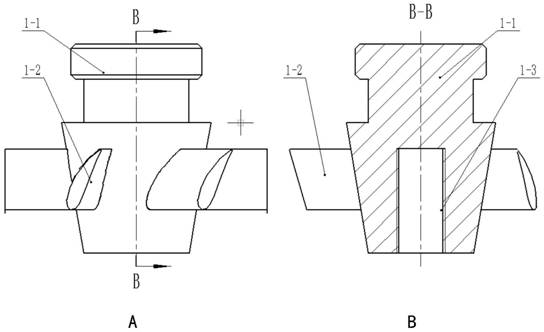

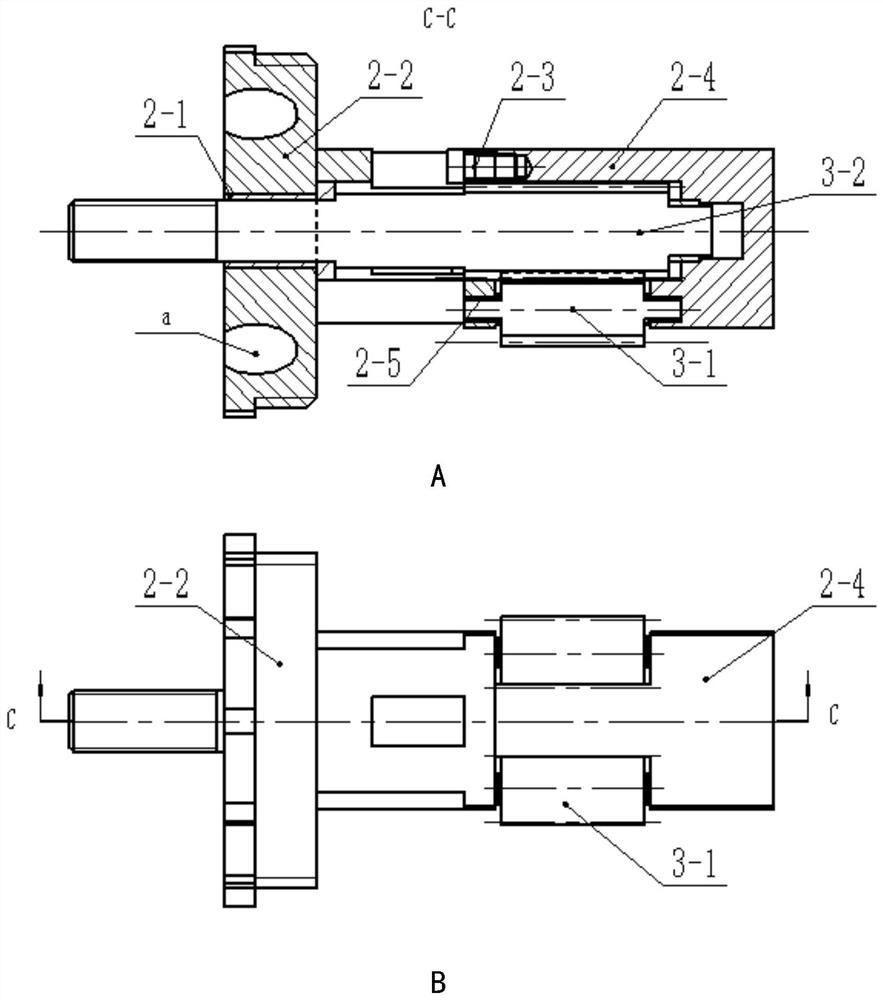

[0026] refer to figure 1 , an underground self-operated forced eddy current drainage gas production device, comprising a spinner 1, the spinner 1 and the output gear of the fixed-axis gear train 3 are connected by threads, and the fixed-axis gear train 3 is located inside the frame 2; The gear train 3 is meshed with the pneumatic actuator end 4 through the internal gear. Both the pneumatic actuator end 4 and the central pipe 5 are inserted with elastic shear pins 8. The elastic shear pins 8 connect the pneumatic actuator end 4 and the central pipe 5. To limit the rotation of the pneumatic actuator end 4 around the axis and the axial movement of the elastic body 7; the pneumatic actuator end 4 is inserted in the turbine stator 9, the central pipe 5 is threadedly connected to the turbine stator 9; the upper part of the central pipe 5 is connected to the frame 2 Through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com