Concrete pump pipe supporting device and using method thereof

A technology for concrete pump pipes and support devices, which is applied in the direction of pipe supports, hoses, pipes, etc., which can solve the problems of poor deformation performance, poor deformation resistance, and poor deformation resistance of concrete pump pipes, and achieve improved buffering Shock absorption effect, good deformation resistance, and improved anti-slip performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

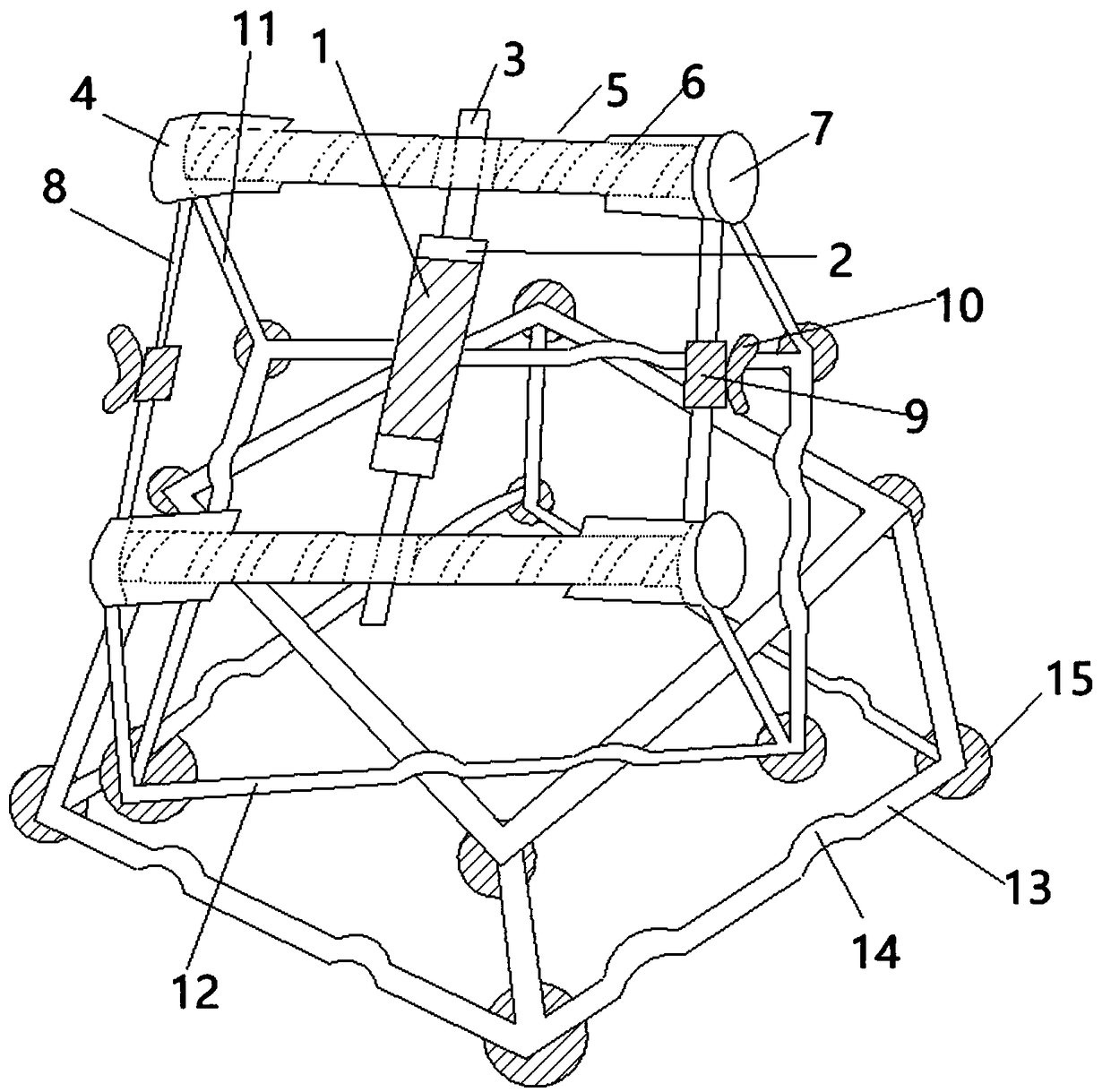

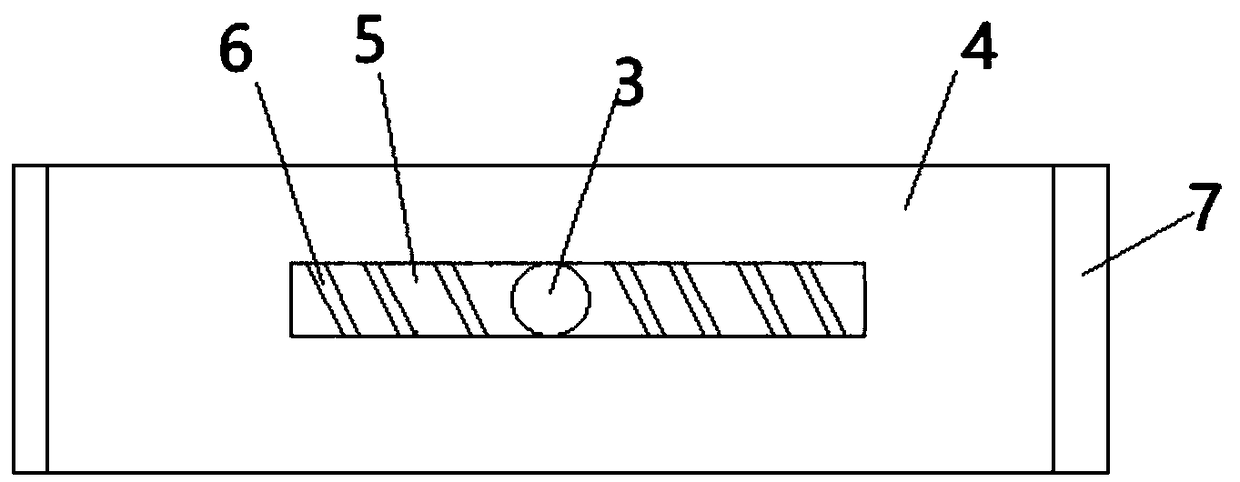

[0023] A concrete pump pipe support device, see figure 1 , the concrete pump pipe supporting device includes a circular tubular bearing tube 1, the bearing tube 1 is sleeved on a cylindrical supporting shaft 2, and both ends of the supporting shaft 2 are concentrically connected with the inner end of the cylindrical rotating shaft 3 , the outer diameter of the supporting shaft 2 is greater than the outer diameter of the rotating shaft 3; the outer end of the rotating shaft 3 is provided with a tubular buffer tube 4, the central axis of the buffer tube 4 is perpendicular to the central axis of the rotating shaft 3, see figure 2 The side walls of the buffer tube 4 are provided with through-hole openings 5, and the outer ends of the rotating shaft 3 respectively pass through the openings 5; the left and right sides of the rotating shaft 3 are respectively provided with buffer springs 6 located in the buffer tube 4, Both the left end and the right end of the buffer tube 4 are pro...

Embodiment 2

[0032] A concrete pump pipe support device is similar to Embodiment 1, the difference is that the outer end of the rotating shaft 3 is provided with a baffle. In this way, the rotating shaft 3 can be prevented from slipping out of the opening 5 due to its movement. The baffle can be a metal plate, and the baffle and the rotating shaft 3 can be connected by welding or screws. The baffle can be a circular plate or a rectangular plate. The outer diameter of the baffle should be larger than the outer diameter of the opening 5 .

Embodiment 3

[0034] A concrete pump pipe support device, similar to Embodiment 2, the difference is that the inner end of the buffer spring 6 is connected to the spring end plate, and the spring end plate is in contact with the side wall of the rotating shaft 3 . Like this, can improve the stability of buffering action structure between buffer spring 6 and rotating shaft 3, avoid the instability that buffer spring 6 directly contacts with rotating shaft 3 or connect and produce, spring end plate can be metal plate, spring end plate and buffer spring 6 can be connected by soldering.

[0035] Preferably, the number of side support plates 10 is more than two, and more than two side support plates 10 extend outward and are sequentially connected. The side support plates 10 can be connected by welding or screws.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com