Hydraulic protection device

A protective device and hydraulic technology, which is applied in the hydraulic field, can solve problems affecting the continuous production and operation of mechanical equipment, unreasonable protection design for operators, and poor heat dissipation effect of hydraulic presses, so as to ensure cooling and heat dissipation effects and improve the safety of malfunctions coefficient, the effect of improving the level of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

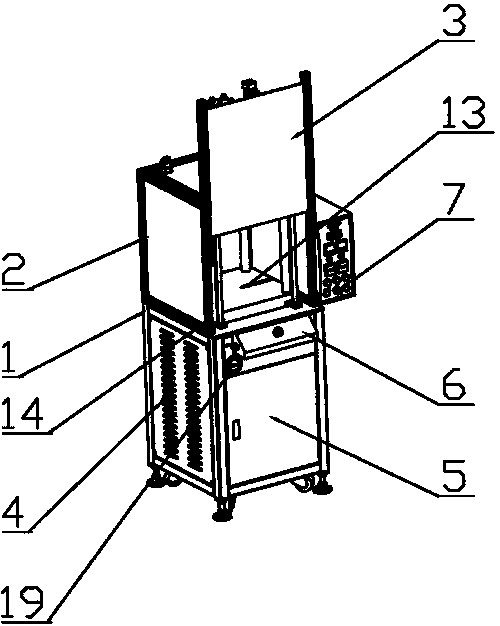

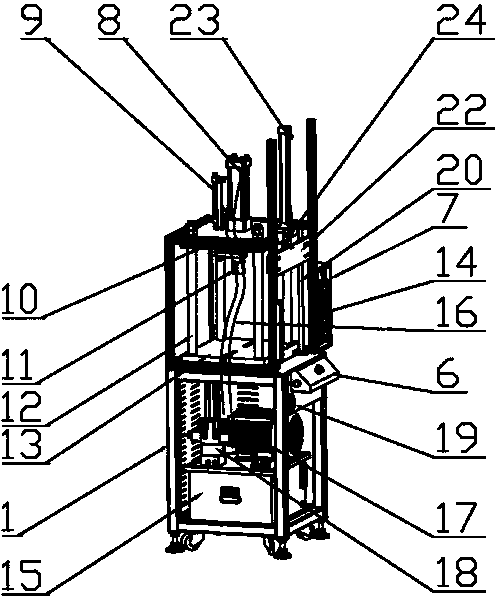

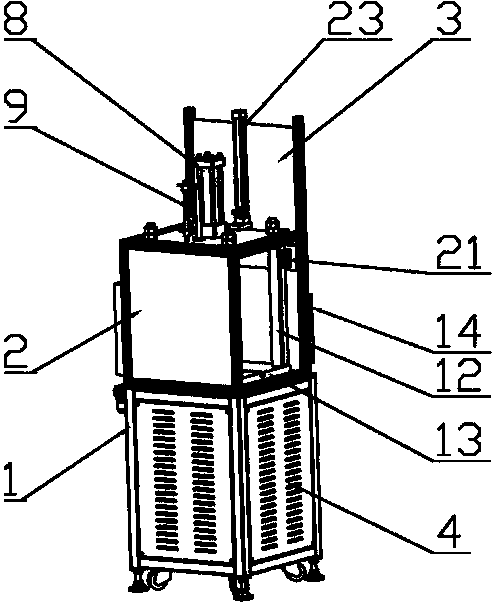

[0018] Such as Figure 1-Figure 3 As shown, the present invention schematically shows a hydraulic protection device.

[0019] The invention discloses a hydraulic protection device, such as figure 1 As shown, it includes frame 1, oil tank 15, oil pipeline 16, motor oil pump 17, hydraulic cylinder 8, solenoid valve group 18, pressure gauge 19 and protective device, and the protective device includes protective cover 2, lifting door 3, shutter door 4, Front door 5, start box 6, control box 7, proximity switch 9, mounting plate 1 10, die head 11, guide rod 12, mounting plate 2 13, detection grating 14, lifting guide column 20, lifting mounting plate 22, lifting cylinder 23 And floating joint 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com