Efficient wall plate cooler

A cooler and wall plate technology, applied in the field of heat exchange equipment and high-efficiency wall plate coolers, can solve the problems of high frequency of maintenance and overhaul of heat exchange equipment, difficulty in cooling or heating process, and affecting normal production, etc., to meet normal production requirements The effect of reducing the frequency and time of maintenance and preventing material accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

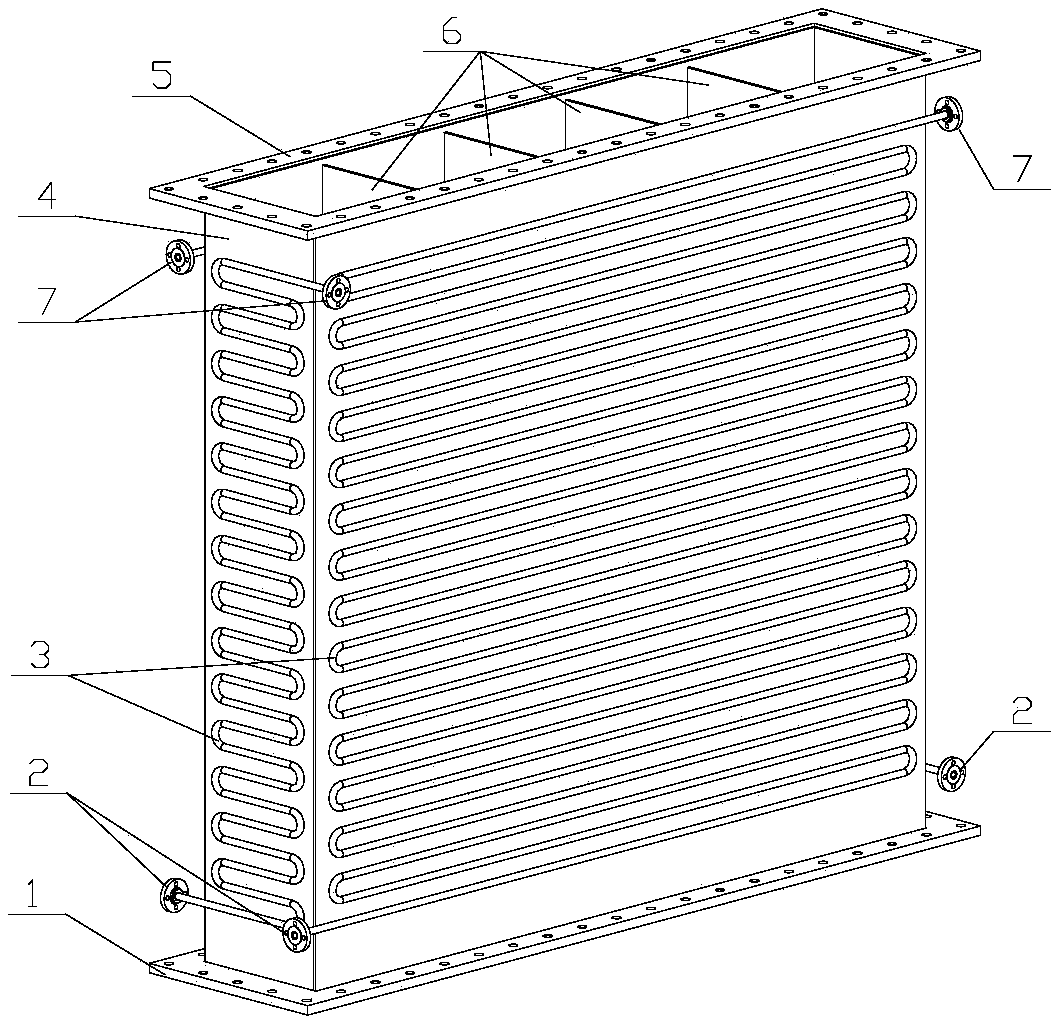

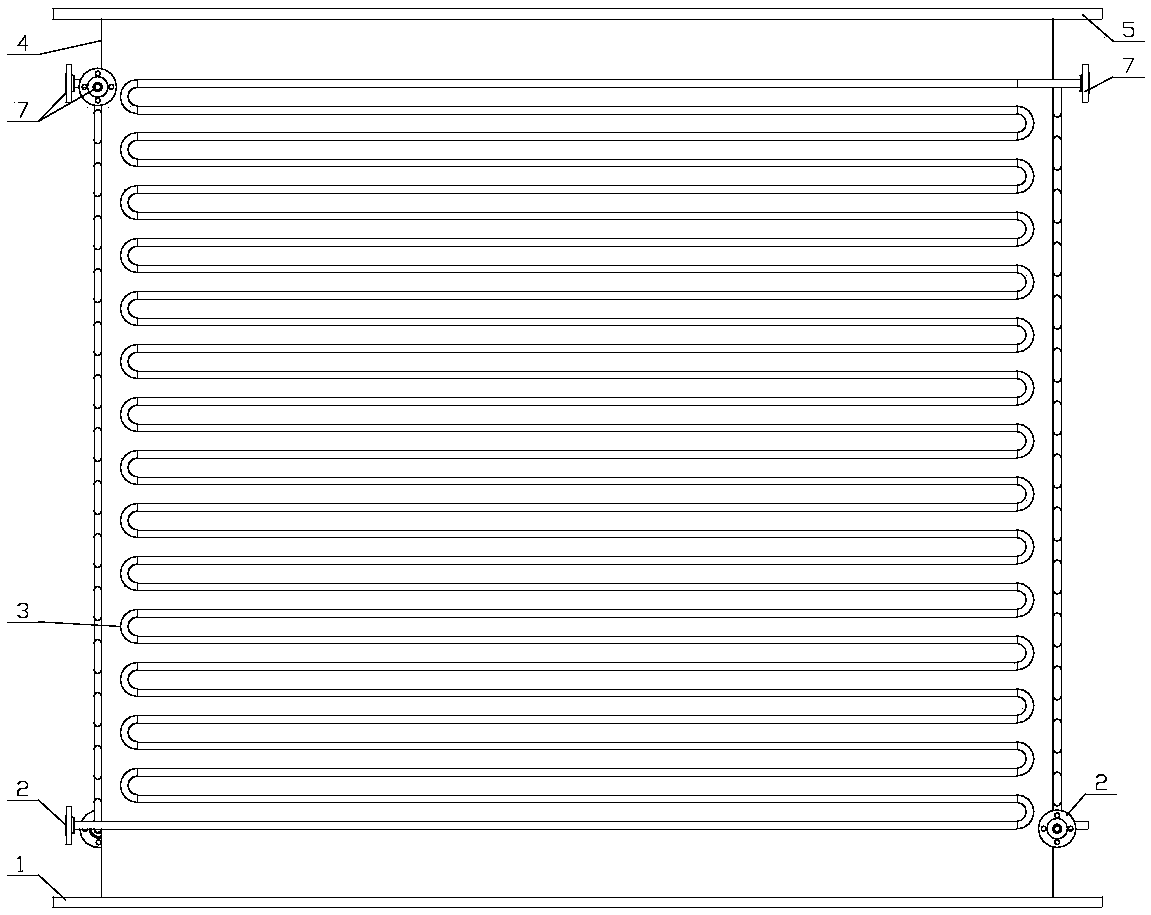

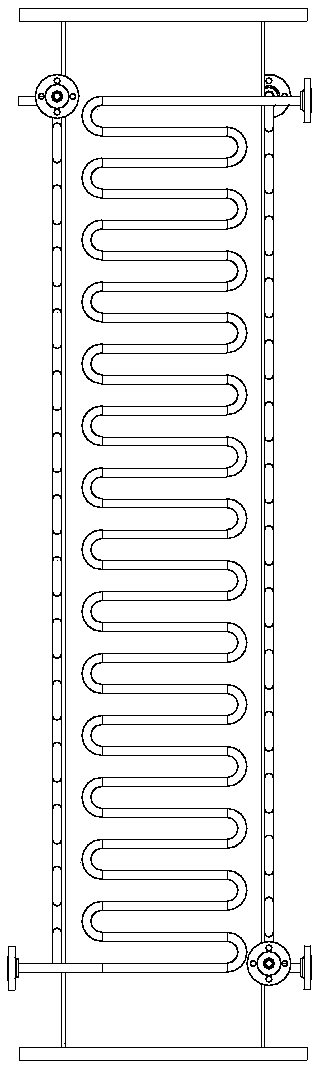

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0023] Such as Figure 1-Figure 4 As shown, a high-efficiency wall panel cooler according to the present invention includes a lower flange 1, a coil pipe 3, a square cylinder 4, an upper flange 5, an intermediate support plate 6, a heat-conducting cement 8 and a U-shaped hook 9, The square cylinder 4 is connected with the upper flange 5 and the lower flange 1 to form the main structure, and the middle support plate 6 is several pieces, which are evenly arranged along the long sides of the square cylinder 4 to support, distribute materials and cool Function: The outer four wall panels of the square cylinder 4 are respectively provided with tightly fitted coils 3, and the coil 3 and the wall panels of the square cylinder 4 are fixed by U-shaped hooks 9 and sealed with 8 heat-conducting glue. die.

[0024] The coil 3 is arranged uniformly in a U-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com