Factory condition monitoring method, device, system and apparatus and storage medium

A state monitoring and storage medium technology, applied in the field of devices, equipment and storage media, factory state monitoring methods, and systems, can solve the problems of increasing the workload of personnel, inability to monitor various changes, and inability to timely feedback the operation of the factory, etc. Real-time monitoring of production conditions and the effect of efficient factory operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

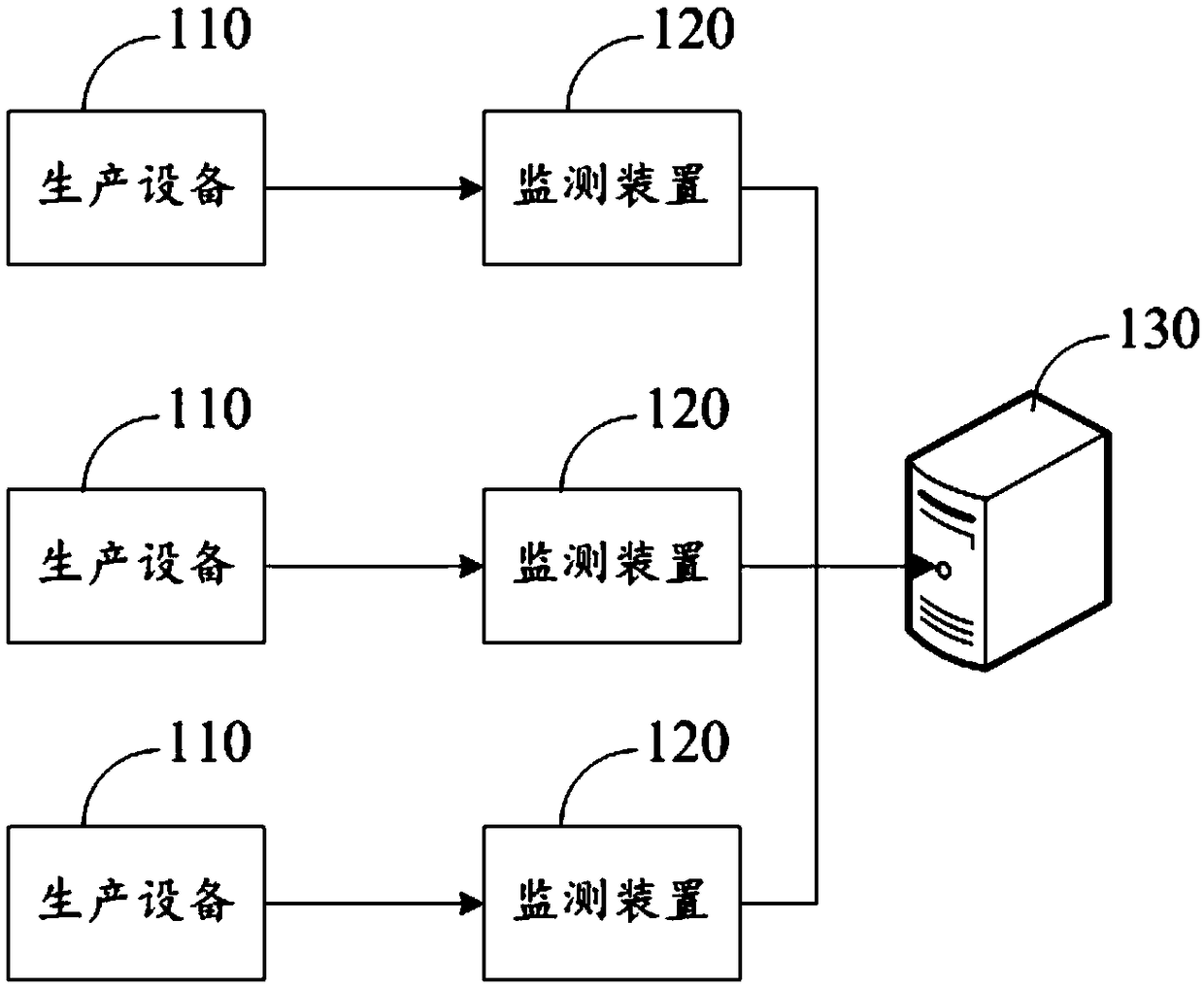

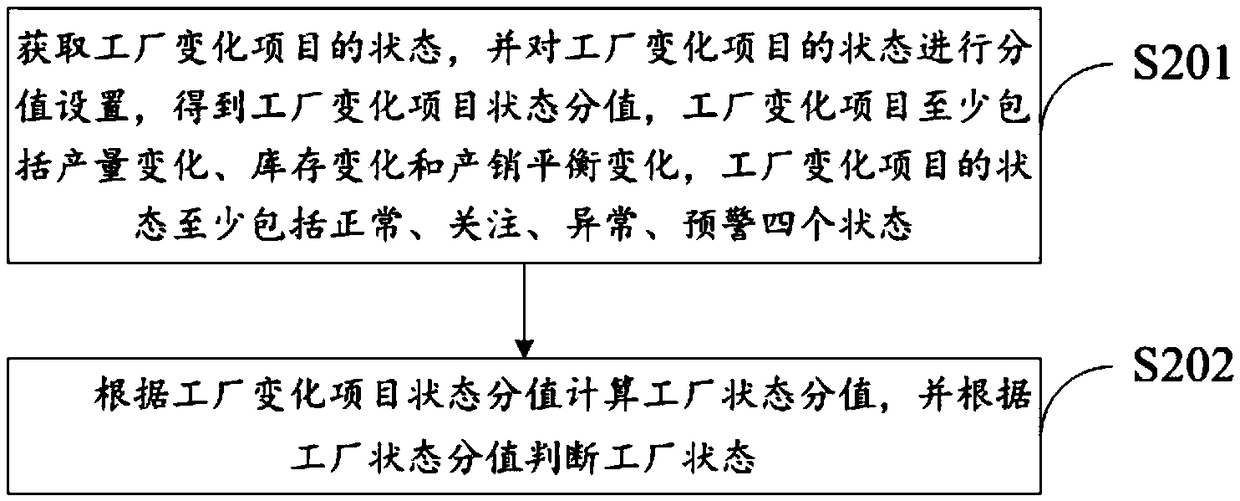

[0033] Such as figure 2 As shown, in one embodiment, a factory state monitoring method is proposed, and this embodiment is mainly applied to the above-mentioned figure 1 The computer device 130 in the computer is used as an example, which may specifically include the following steps:

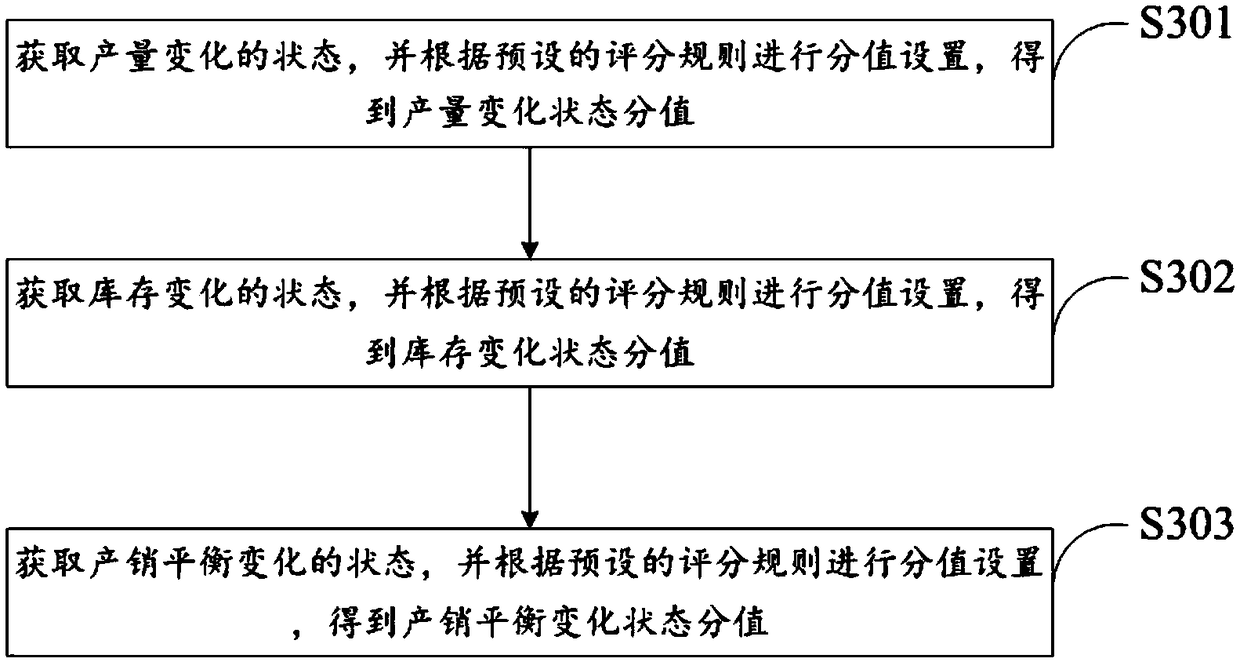

[0034] Step S201, obtain the state of the factory change item, and set the score of the state of the factory change item to obtain the state score of the factory change item. The factory change item includes at least output change, inventory change and production-sales balance change, and the state of the factory change item Including at least four states of normal, concerned, abnormal, and early warning;

[0035] Step S202, calculating the factory status score according to the status score of the factory change item, and judging the status of the factory according to the factory status score.

[0036] In the embodiment of the present invention, the factory change item refers to various main ...

Embodiment 2

[0051] Such as Figure 4 As shown, it is a flow chart of the factory status monitoring device provided in the embodiment of the present invention. In one embodiment, a factory status monitoring device is provided. The factory status monitoring device can be integrated into the above-mentioned computer equipment 130, specifically Can include:

[0052] The factory change state acquisition unit 401 is used to obtain the state of the factory change project, and set the score of the state of the factory change project to obtain the state score of the factory change project. The factory change project includes at least output change, inventory change and production-sales balance change , the state of the factory change item includes at least four states: normal, concerned, abnormal, and early warning;

[0053] The factory state judging unit 402 is configured to calculate the factory state score according to the state score of the factory change item, and judge the factory state acc...

Embodiment 3

[0069] Such as Image 6 As shown, it is a factory status monitoring system provided by an embodiment of the present invention, and a factory status monitoring system provided by an embodiment of the present invention includes:

[0070] A factory change monitoring device 601, configured to monitor the factory change state;

[0071] In the embodiment of the invention, the factory change monitoring device 601 may be a device with data collection and processing functions including but not limited to sensors, sensors, cameras, etc., used to monitor the status of change items such as production equipment or warehouses, and Store and share status information in the form of data after processing.

[0072] The factory status monitoring center 602 includes the factory status monitoring device in the above embodiment, which is used to obtain the status of the factory change items collected by the monitoring device, and process the status of the factory change items to judge the factory ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com