Tensile fireproof waterproof flame-retardant cable

A flame-retardant cable and tensile-type technology, which is applied in the direction of fire-resistant coatings, insulated cables, cables, etc., can solve the problems of unfavorable safe and stable work of wires and cables, poor tensile performance, and ineffective fire-resistant and flame-retardant cables, etc., to achieve Good fire prevention and flame retardant effect, not easy to stretch and break, good fire prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further described in conjunction with the following examples.

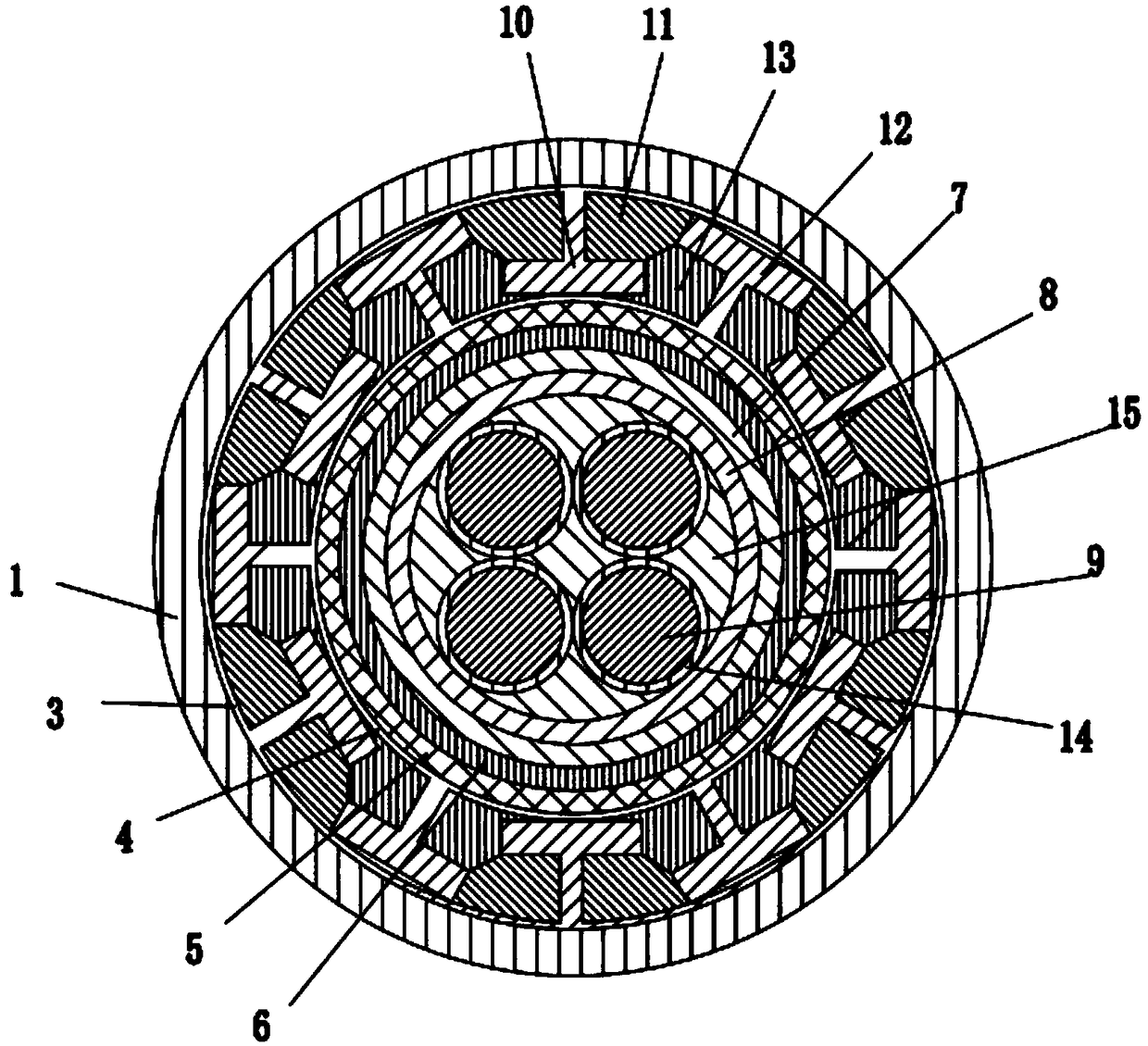

[0014] A specific embodiment of a tensile type fireproof, waterproof and flame-retardant cable of the present invention is as follows: figure 1 As shown, it includes an outer sheath 1, a first reinforcement layer 3, a second reinforcement layer 4, a waterproof layer 5, a first fireproof layer 6, a second fireproof layer 7, and a steel tape armor protective layer 8 arranged in sequence from outside to inside. And the core 9, the filler 15 is filled between the core 9 and the steel tape armor protection layer 8, the filler 15 is made of aramid fiber braided material, and the use of aramid fiber braided material can increase the flexibility of the cable , so that the cable is not easy to be stretched and broken, and the tensile strength of the wire and cable is strongly enhanced, and the tensile strength of the wire and cable can be continuously maintained after the steel tape armor pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com