Ditch picker

A picker and furrow technology, applied in the agricultural field, can solve the problems of high labor intensity and low picking efficiency, and achieve the effect of improving picking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

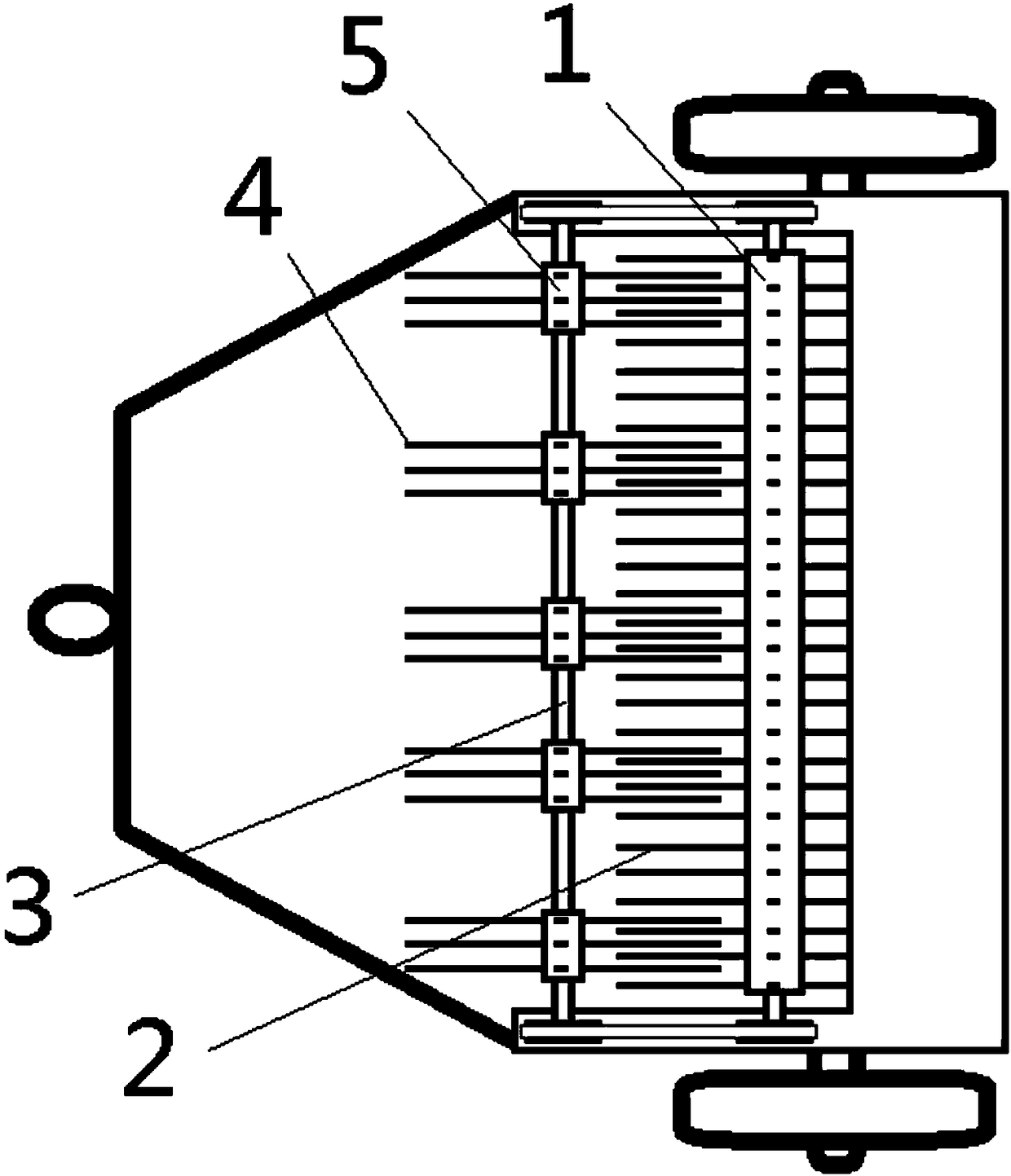

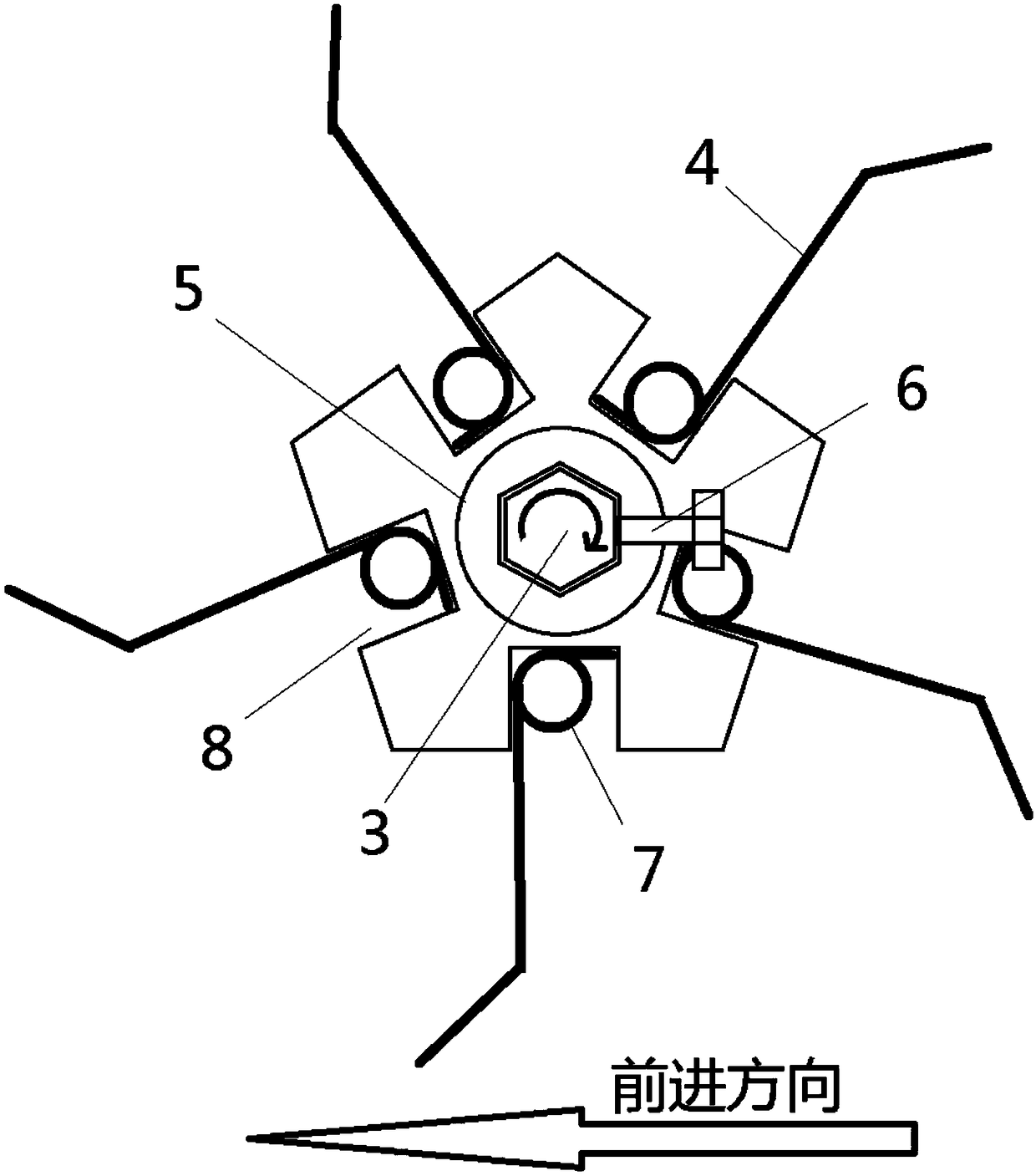

[0027] The following will be described in detail in conjunction with the accompanying drawings in the embodiments of the present invention. It should be noted that the front part of the feed port of the traction straw baler is provided with a claw picking mechanism. The outer surface is densely covered with claw hooks 2, and the roller claw pick-up mechanism rotates reversely in the pulling direction through the driving mechanism.

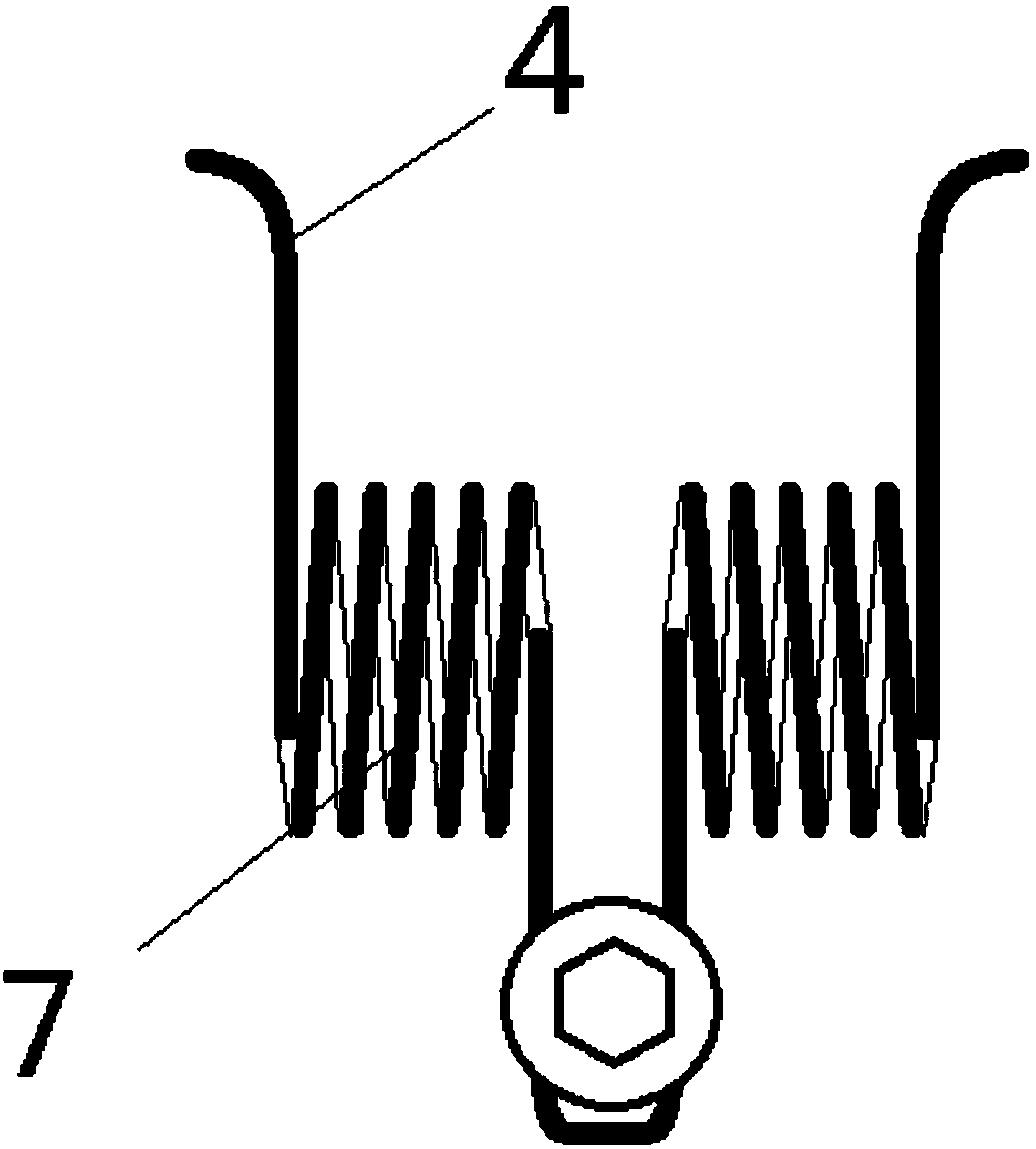

[0028] see figure 1 , figure 2 , image 3 , the ditch picker mainly includes: the horizontal shaft 3 arranged horizontally in front of the main shaft 1 of the above-mentioned traction straw baler, the horizontal shaft 3 rotates synchronously and reversely with the main shaft 1 through the transmission mechanism; The claws 4 and the claw hooks 2 on the main shaft 1 are alternately arranged.

[0029] In the above structure, the length and lateral spacing of the elastic claws 4 are adapted according to the width and depth of the furrow, so the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com