Camber beam installing and welding tool for equipment cabin and welding method thereof

A technology for assembling welding tooling and equipment cabin, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problem of idle resource waste of tooling, and achieve the effect of realizing all-position welding, saving adjustment time and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

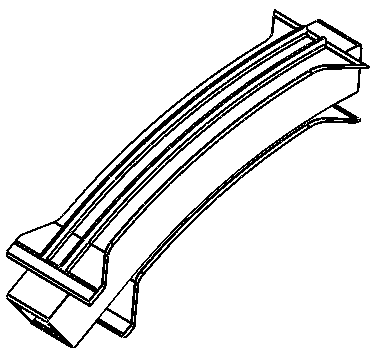

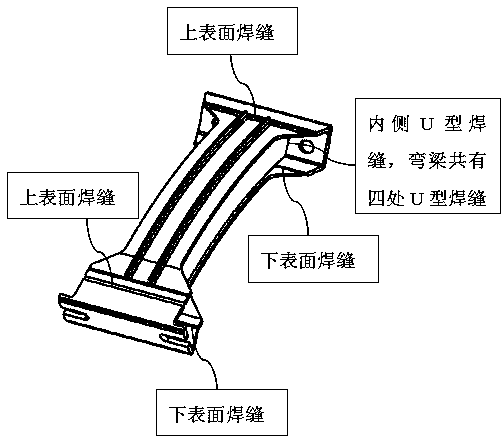

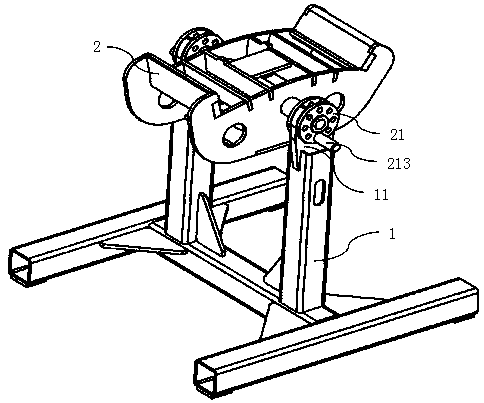

[0036] Provide a high-speed motor car box-type equipment compartment curved beam assembly welding tool, the curved beam structure is as follows figure 2 as shown, figure 1 is the middle structure of the curved beam, figure 2 In order to use this tooling to weld the middle part of the curved beam and the two ends of the curved beam, the overall structure of the curved beam is as follows: image 3 As shown, the tooling includes a bracket 1 with legs 11, a profiling module 2 arranged above the bracket 1 and capable of accommodating a curved beam. The curvature of the upper surface of the profiling module matches the curvature of the curved beam. The surface is provided with a support mechanism 21 that can be inserted into the support leg 11 of the bracket to make the profiling module be in different angle states.

[0037] Wherein, the support mechanism 21 includes the support rods 211 symmetrically arranged on both sides of the profiling module and the limit plate 212 fixedly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com