Composite concave-convex panel based on high frequency

A high-frequency, board technology, applied in wood treatment, wood heating, wood heat treatment, etc., can solve the problems of high cost, inability to reflect the wood texture, and inability to reflect the concave-convex texture characteristics of each board, so as to reduce the deformation recovery rate and prepare The method is simple and improves the effect of depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

[0046] Embodiment 1-7 provides 7 kinds of composite concave-convex plates, all prepared by the following steps:

[0047] a. Pretreatment: choose a density not exceeding 0.5kg / m 3 Wooden boards, the moisture content of the boards should be controlled at 8%-18%, and the thickness should not exceed 2cm;

[0048] b. Heating treatment: select N wood boards after pretreatment to be stacked and placed in contact, N≥2, heat the pretreated wood boards with high frequency until the temperature of the boards is 80°C-100°C, and keep warm for 2-3min;

[0049] c. Pressure treatment: Compress the heat-treated wood boards according to the preset compression rate S, the preset compression rate is preferably 10%-70%, the thickness of N wood boards after contact is U1, and the thickness after pressure is U2 , then S=U2 / U1;

[0050] d. Curing treatment: heat the wood board after pressure treatment to 200-240°C with high frequency and keep it warm for 4-6 minutes under the condition that the pre...

Embodiment 8

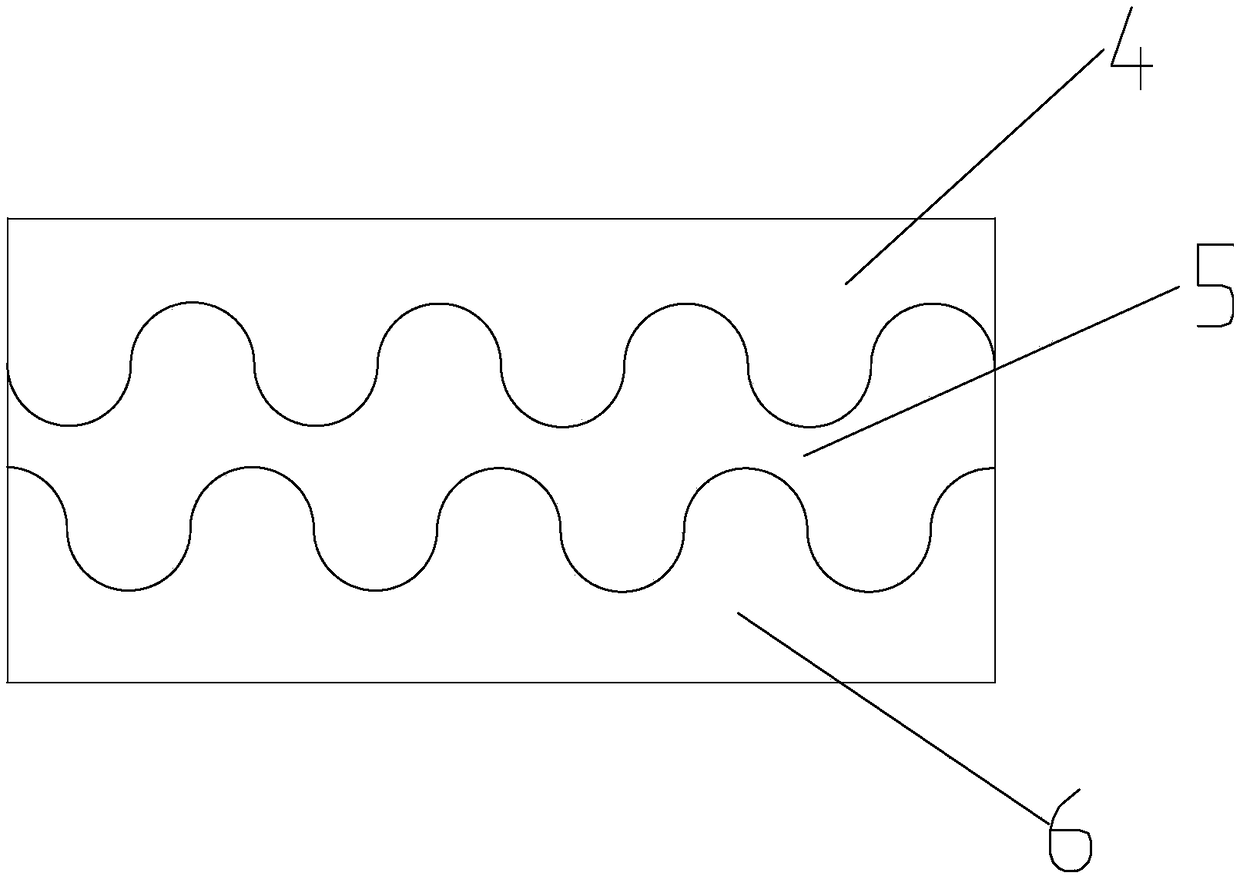

[0066] Embodiment 8 Composite concave-convex sheet based on high frequency

[0067] Embodiment 8 provides a composite concave-convex sheet; the composite concave-convex sheet is prepared by the following steps:

[0068] a. Pretreatment: choose a density not exceeding 0.5kg / m 3 Wooden boards, the moisture content of the boards should be controlled at 8%-18%, and the thickness should not exceed 2cm;

[0069] b. Heat treatment: select 3 wood boards after pretreatment and place them in contact, and the density of the 3 wood boards is 0.46kg / m3 respectively 3 、0.39kg / m 3 、0.43kg / m 3 , control the moisture content of the plank to be 9%, 11%, 13%, respectively, and the thickness to be 0.6cm, 0.8cm and 0.4cm respectively, heat the pretreated plank to the temperature of the plank with high frequency to 100°C, and the heating time is 3min ;

[0070] c. Pressure treatment: compress the wood boards after heat treatment according to the preset compression rate S, the preset compressio...

Embodiment 5

[0101] Cooling treatment step is general embodiment 5;

[0102] Wherein, the total thickness of the three wood boards after the pressure treatment in step c is 0.9dm, and the upper surface and the lower surface of the pretreated wood boards are not covered with electrical insulating cloth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com