Design method of hull deck surface platform molded line

A design method and a platform-based technology, applied in ship design, ship parts, ship construction, etc., can solve problems such as substandard flatness requirements, brittle deck materials, failure to pass inspections, etc., to meet performance requirements and improve manufacturing Efficiency and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

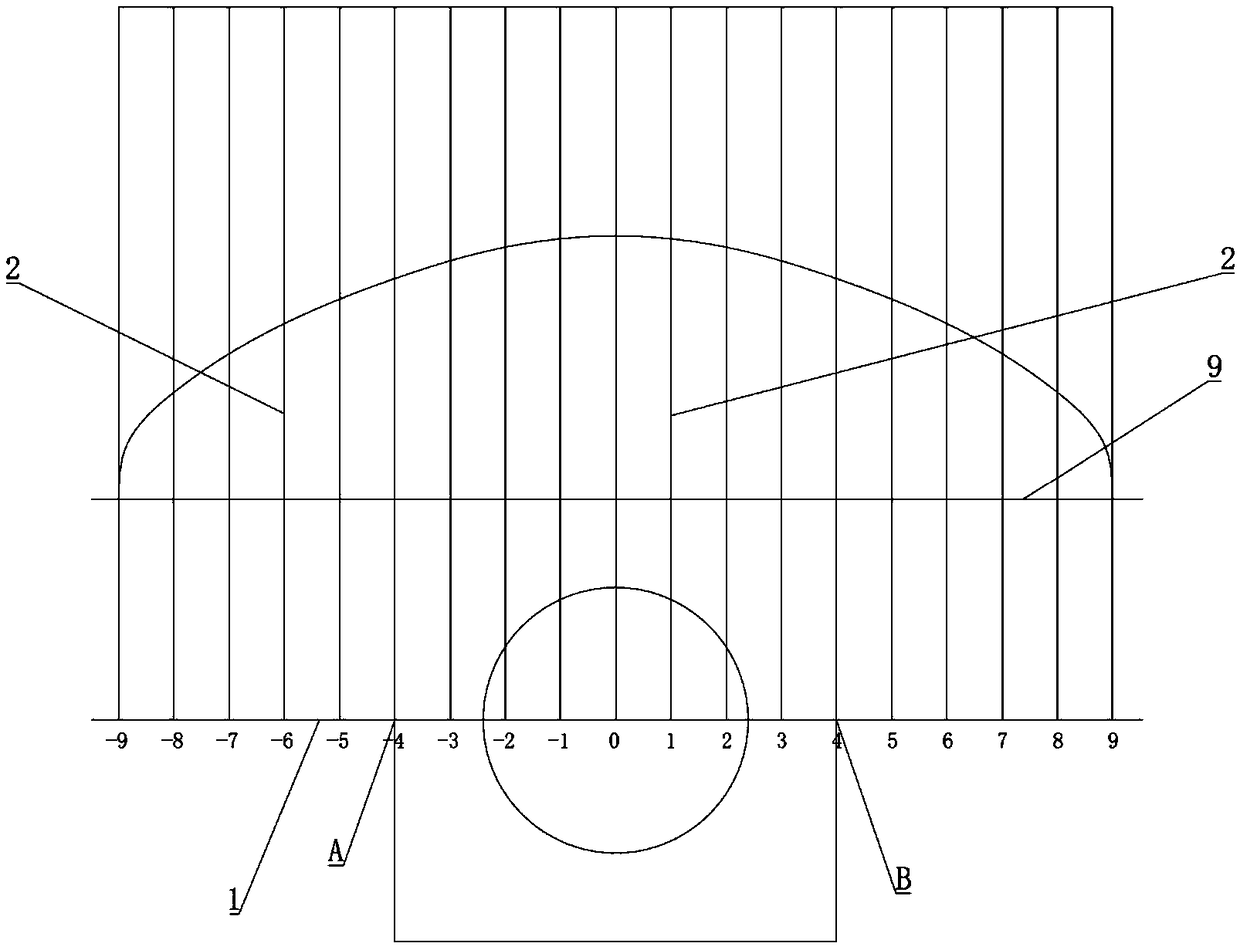

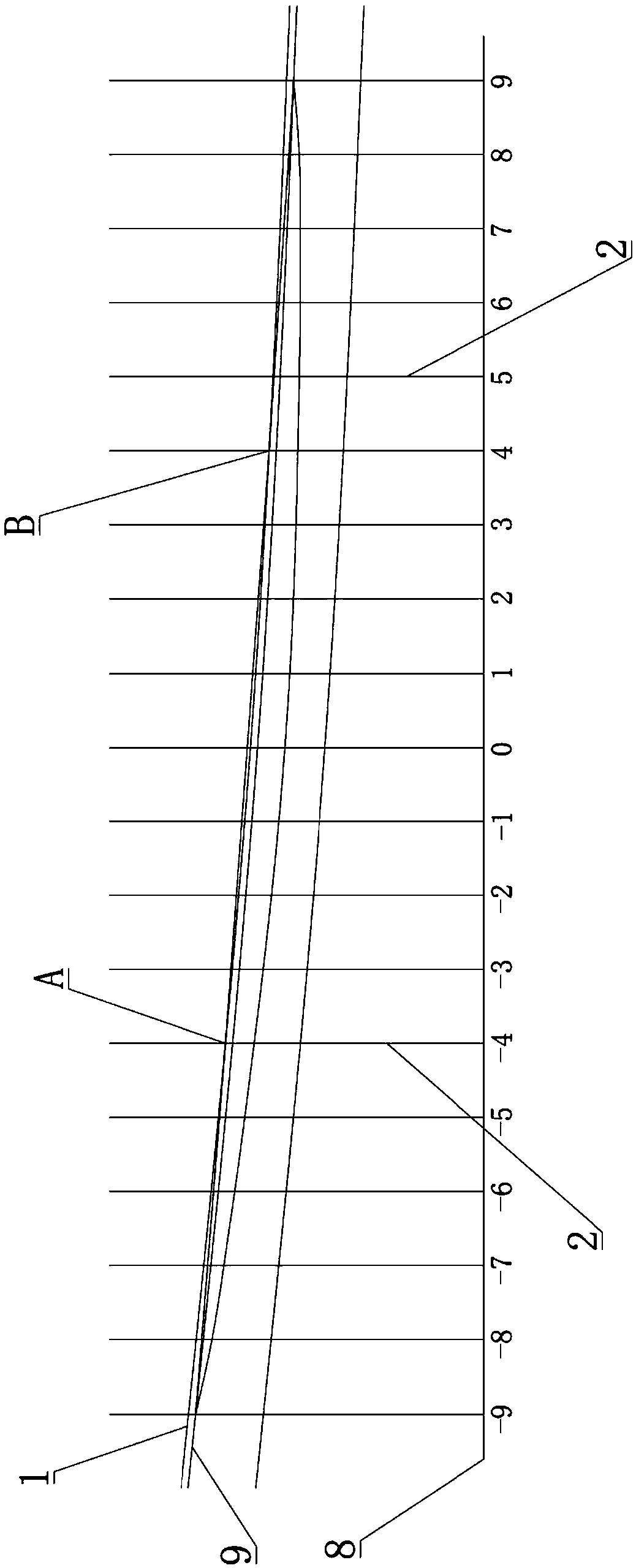

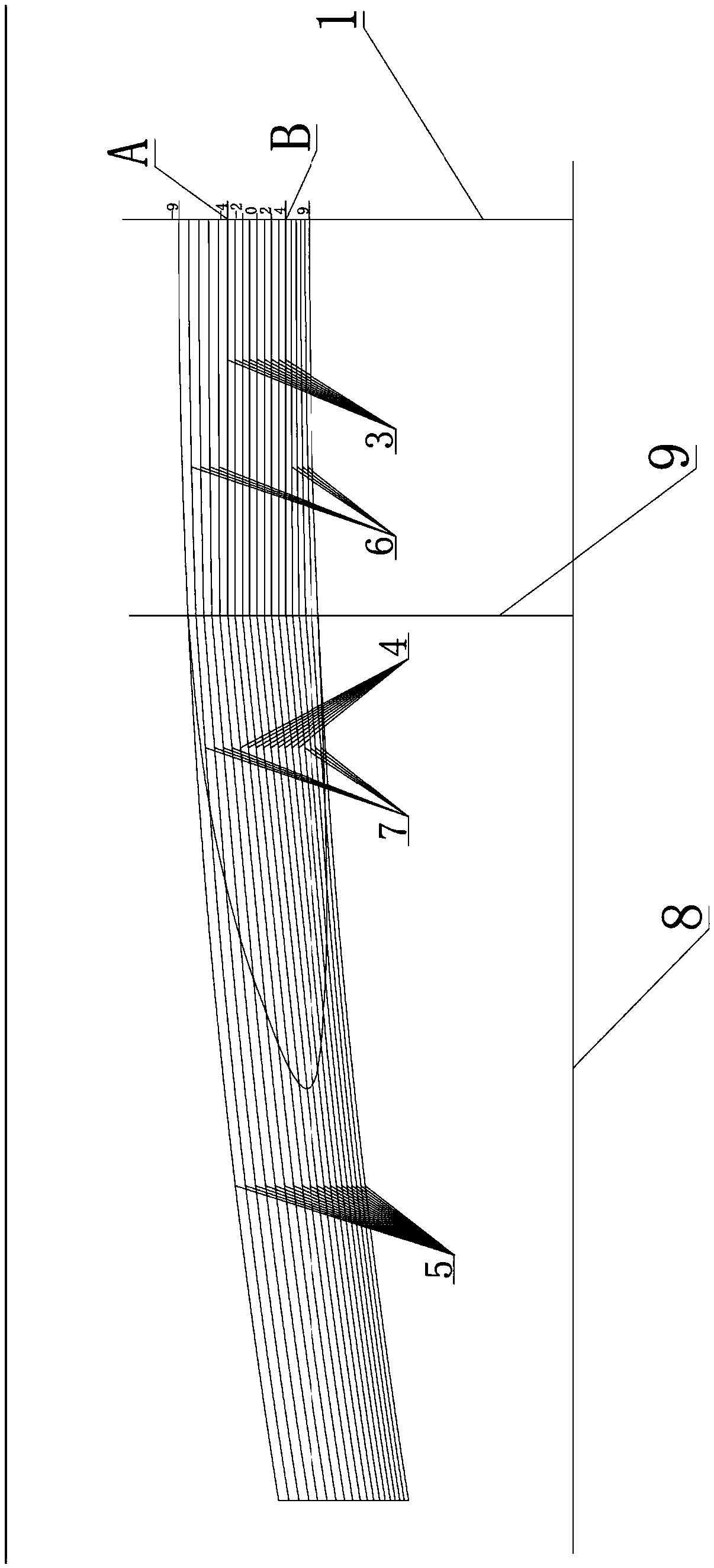

[0029] refer to Figure 1 ~ Figure 4 , the present embodiment provides a method for designing the profile of a hull deck surface platform, comprising the following steps:

[0030] Obtain the installation opening line of the landing grille on the deck type line plan, and take 1.5 to 2 times the diameter of the opening as the side length of the square plate, so that the center of the square plate coincides with the center of the opening circle and is located in the center of the deck centerline 1. , then the square plate intersects with the center line 1 of the deck at points A and B;

[0031] Draw the projections of points A and B on the side view of the deck mold line, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com