Graphene heating paint and preparation method thereof

A heating coating and graphene technology, applied in conductive coatings, epoxy resin coatings, coatings, etc., can solve the problems of unstable heating effect, weak substrate adhesion, poor bending performance, etc., and achieve low cost and high temperature rise The effect of short time and long working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

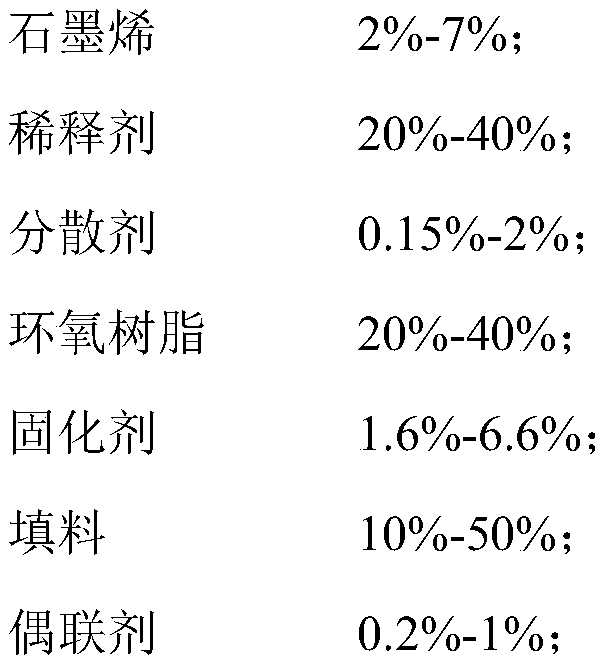

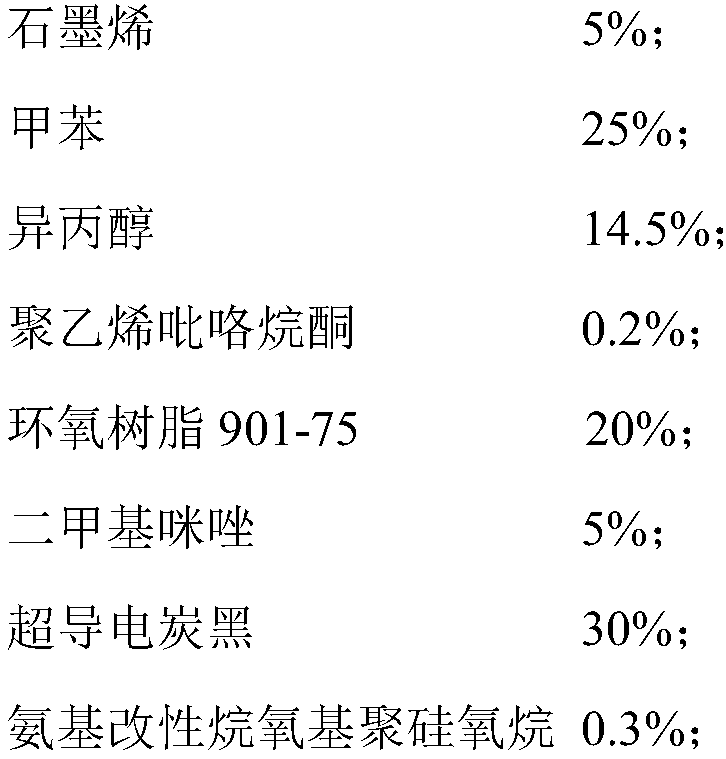

[0038] A kind of graphene heating coating, comprises the following components by weight percentage:

[0039]

[0040] The graphene heating coating has a fineness of 40 μm and a solid content of 55.8%.

[0041] The preparation method of above-mentioned graphene heating coating, comprises the following steps:

[0042] (1) carry out ultrasonic dispersion to graphene;

[0043] (2) Graphene, toluene, isopropanol, polyvinylpyrrolidone after step (1) process are joined in the stirrer and stirred 30min, and stirring speed is 1000r / min, forms graphene dispersion liquid;

[0044] (3) Epoxy resin 901-75, dimethylimidazole, superconducting carbon black, amino-modified alkoxypolysiloxane and graphene dispersion are mixed and stirred, and the stirring speed is 1000r / min to form a mixture;

[0045] (4) Grinding the mixture by a grinder, when the mixture reaches a fineness of 40 μm, the solid content is 55.8%. Promptly obtain graphene exothermic coating.

Embodiment 2

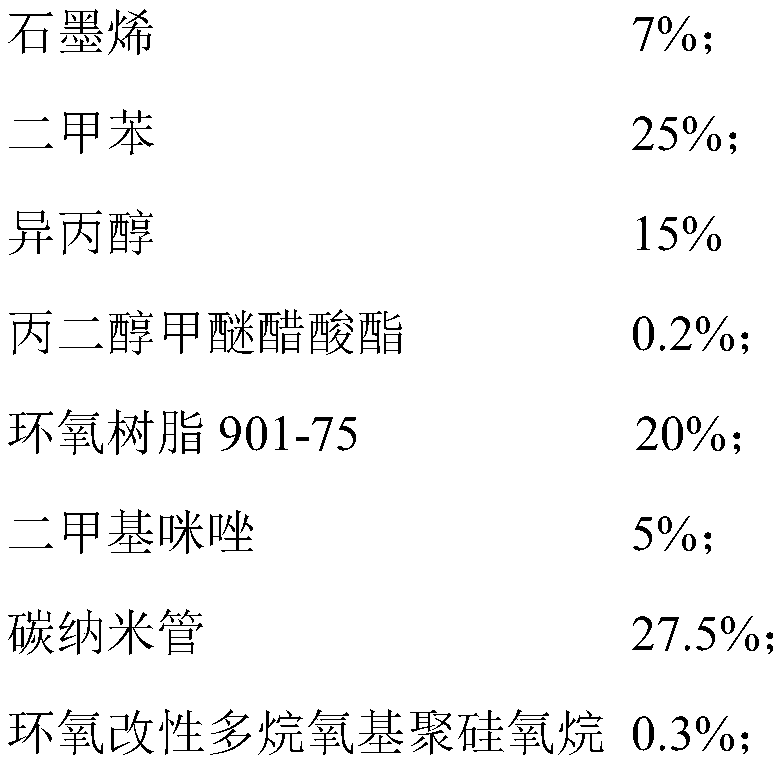

[0047] A kind of graphene heating coating, comprises the following components by weight percentage:

[0048]

[0049] The graphene heating coating has a fineness of 40 μm and a solid content of 55.5%.

[0050] The preparation method of above-mentioned graphene heating coating, comprises the following steps:

[0051] (1) carry out ultrasonic dispersion to graphene;

[0052] (2) Graphene, dimethylbenzene, isopropanol, propylene glycol methyl ether acetate after step (1) process are joined in agitator and stirred 30min, and stirring speed is 1000r / min, forms graphene dispersion liquid;

[0053] (3) Mix and stir epoxy resin 901-75, dimethylimidazole, carbon nanotubes, epoxy-modified polyalkoxypolysiloxane and graphene dispersion at a stirring speed of 1000r / min to form a mixture ;

[0054] (4) Grinding the mixture by a grinder, when the mixture reaches a fineness of 40 μm, the solid content is 55.5%. Promptly obtain graphene exothermic coating.

Embodiment 3

[0056] A kind of graphene heating coating, comprises the following components by weight percentage:

[0057]

[0058]

[0059] The graphene heating coating has a fineness of 40 μm and a solid content of 54.9%.

[0060] The preparation method of above-mentioned graphene heating coating, comprises the following steps:

[0061] (1) carry out ultrasonic dispersion to graphene;

[0062](2) Graphene, xylene, isopropanol, polyethercarbonate after step (1) process are joined in the stirrer and stirred 30min, and stirring speed is 1000r / min, forms graphene dispersion liquid;

[0063] (3) Epoxy resin 128, diaminodiphenyl sulfone, tourmaline powder, epoxy-modified polyalkoxy polysiloxane and graphene dispersion are mixed and stirred, and the stirring speed is 1000r / min to form a mixture;

[0064] (4) Grinding the mixture by a grinder, when the mixture reaches a fineness of 40 μm, the solid content is 54.9%. Promptly obtain graphene exothermic coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com