Air pressure feeding box thickness adjusting device

A technology of air pressure feeding and thickness adjustment, applied in the directions of fiber feeding, textile and papermaking, fiber processing, etc., can solve the problems of unguaranteed personnel and equipment safety, reduced fiber silo capacity, limited adjustment range, etc. Personal safety and equipment safety, air pressure stability, and the effect of ensuring lateral uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The features and principles of the present invention will be described in detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

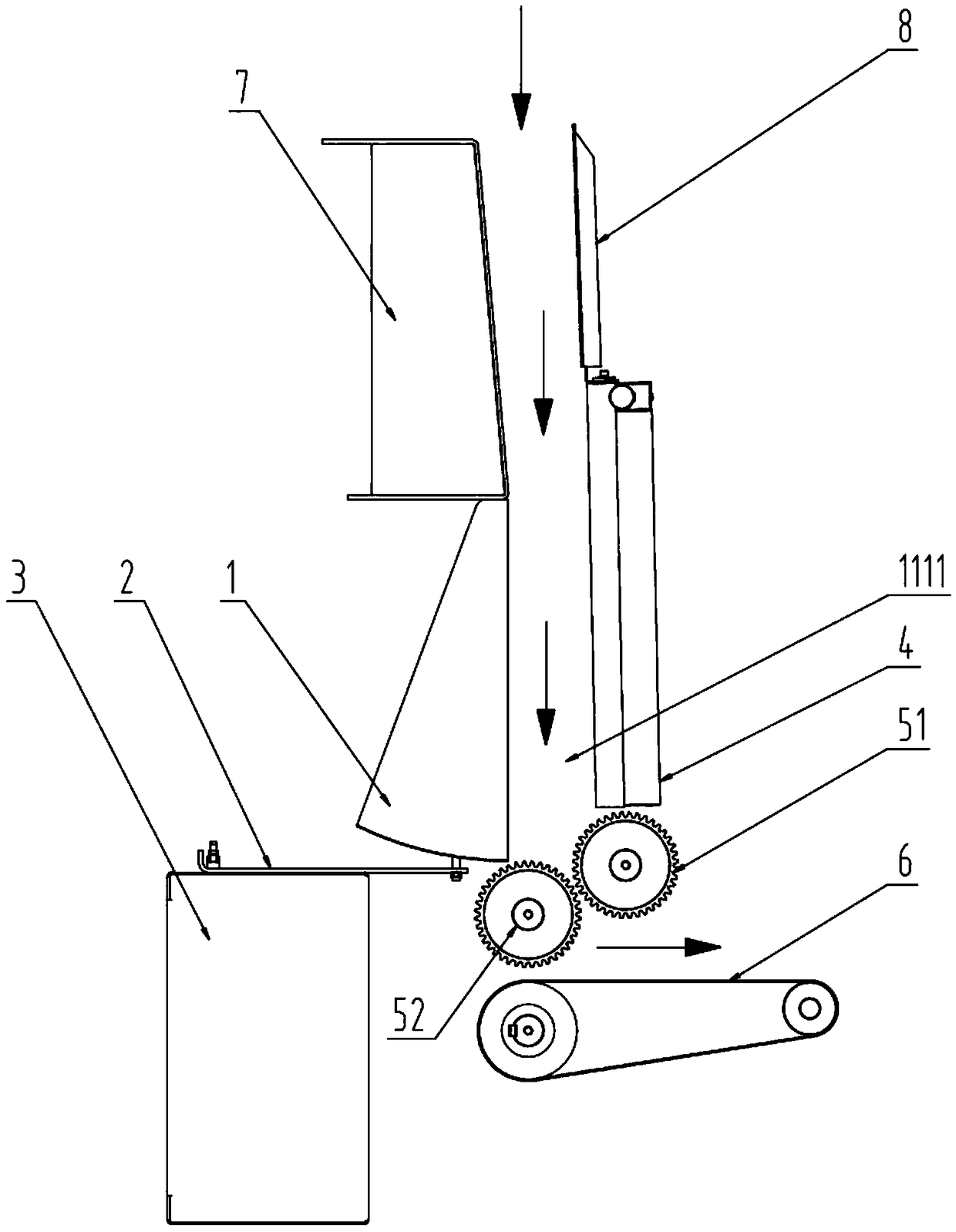

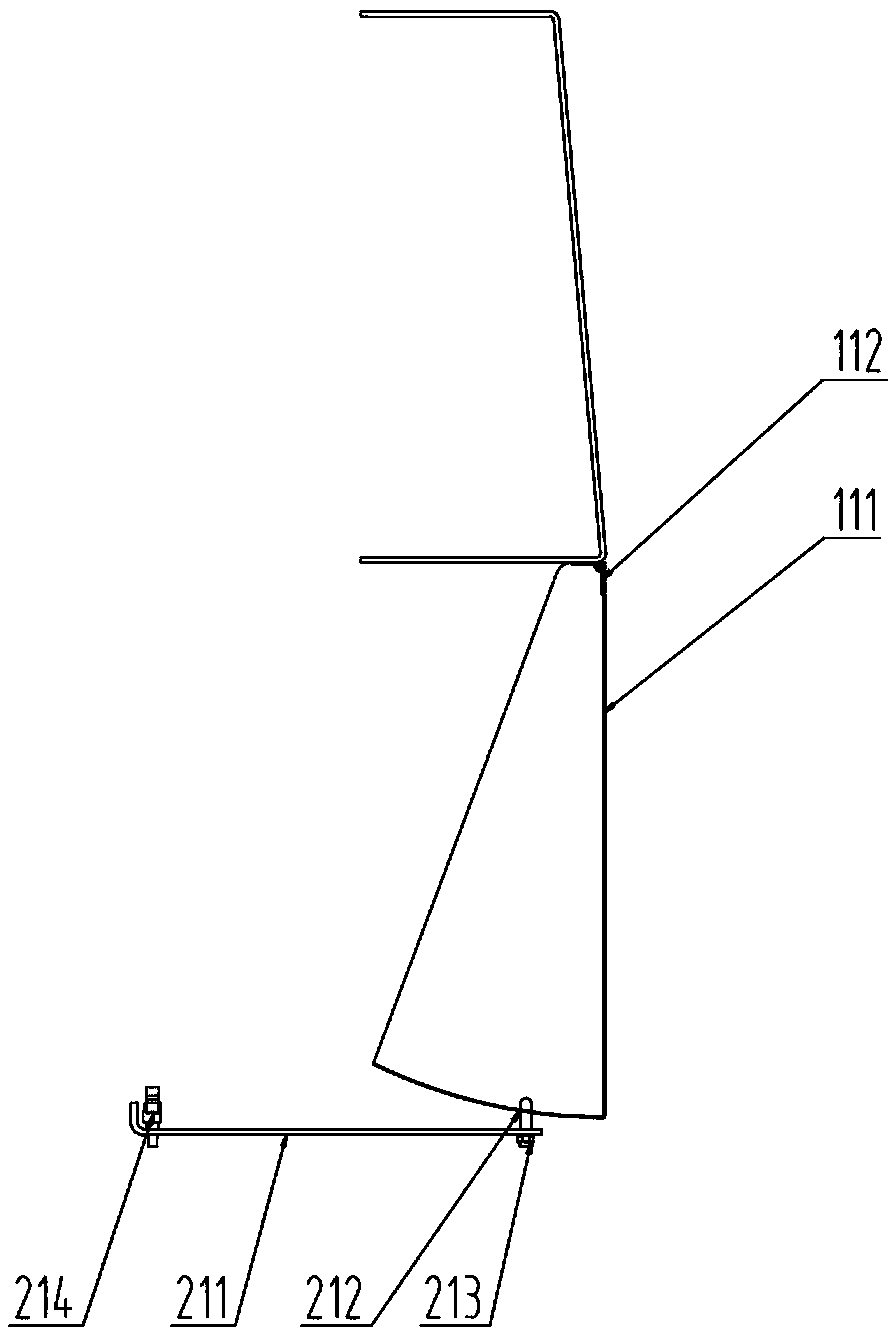

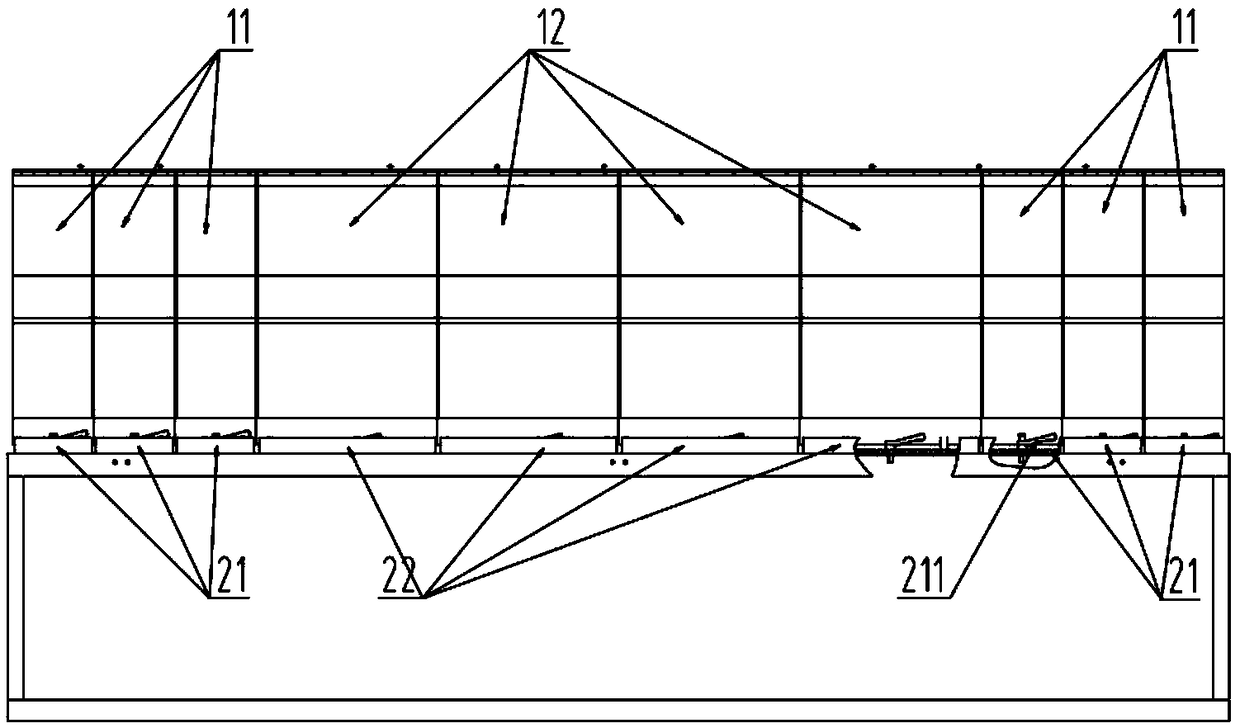

[0029] Such as Figure 1 to Figure 3 As shown, the present invention includes a baffle plate 1, a baffle plate 2, a cotton output roller assembly, a cotton shock board and an output curtain assembly, and also includes a fan-shaped plate assembly 1 and a push plate assembly 2. Among them, the fan-shaped plate assembly 1 is divided into a small fan-shaped plate assembly 11 and a large fan-shaped plate assembly 12, and the push plate assembly 2 is divided into a small push plate assembly 21 and a large push plate assembly 22; the fan-shaped plate assembly 1 and the vibration cotton plate 4 form a fiber warehouse 1111. Adjust the thickness of the fiber web layer by adjusting the volume of the fiber bin 1111.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com