A Method for Reducing Refractive Index of Ceramic Oxide Optical Thin Film

A technology of ceramic oxide and optical thin film, applied in optics, optical components, sputtering coating, etc., to achieve the effect of ensuring lateral uniformity, feasible operation, and reducing refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

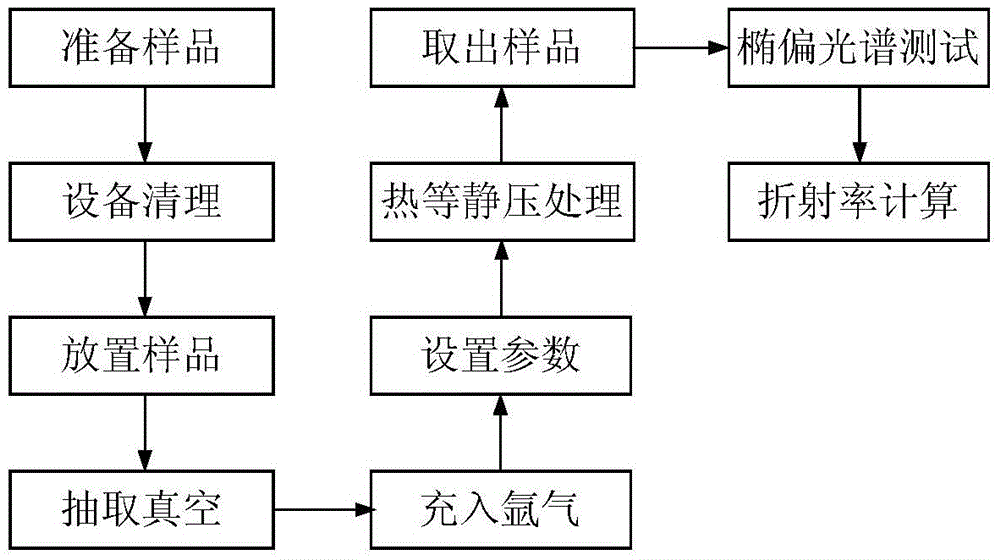

Method used

Image

Examples

Embodiment 1

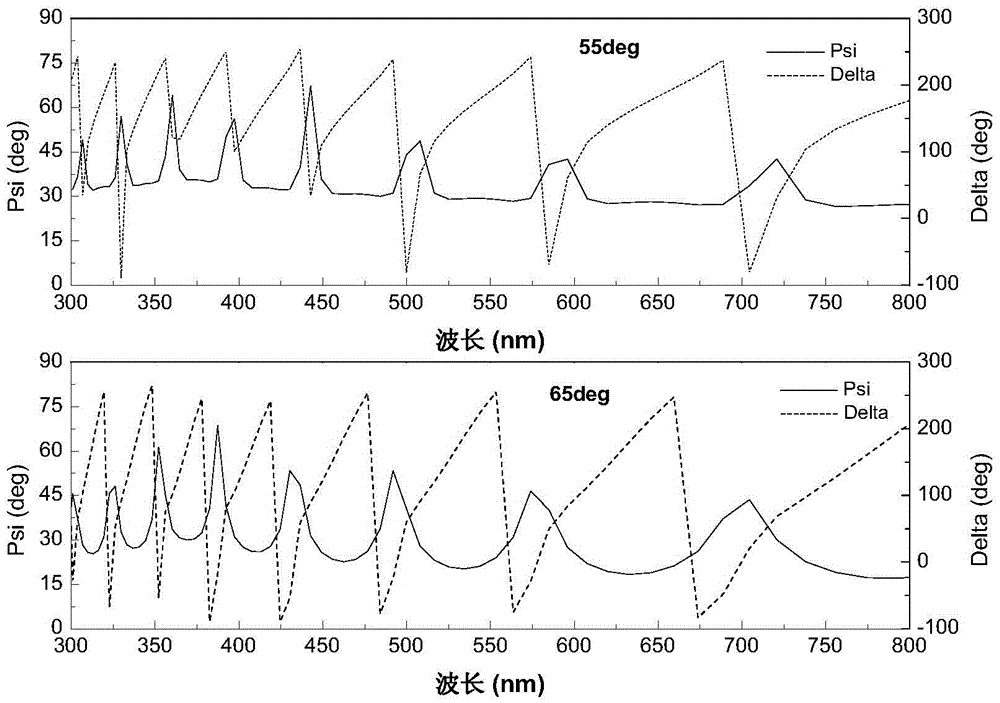

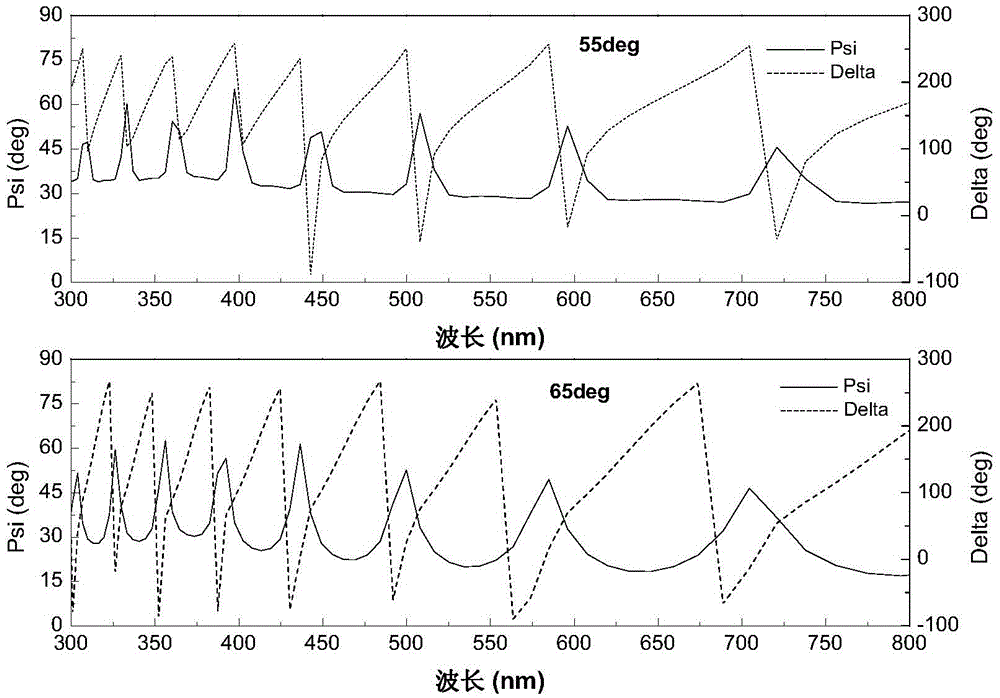

[0042] Preparation of HfO by Ion Beam Sputtering 2 Film Refractive Index Modification:

[0043] 1) Si substrate with ultra-smooth surface, surface roughness ~0.3nm, size Φ40×0.30mm, HfO prepared by ion beam sputtering deposition method 2 film;

[0044] 2) Ion beam sputtering deposition of HfO 2 The thin film adopts high-purity metal Hf target material, the purity is ≥99.95%, and the vacuum degree of the back is better than 1.0×10 -3 P, the ion beam voltage is 1250V, the ion beam current is 600mA, the oxygen flow rate is 25sccm, and the deposition time is 1h;

[0045] 3) Prepared HfO 2 The film is placed in a quartz petri dish, and processed in an Ar atmosphere of a hot isostatic pressing device, with a pressure of 50Mpa, a temperature of 300°C, and a processing time of 16 hours;

[0046] 4) Use an ellipsometer to measure the reflection ellipsometric parameters Ψ(λ) and Δ(λ) of the silica film, set the measurement wavelength range to 300nm-800nm, the measurement step size ...

Embodiment 2

[0049] Preparation of Ta by Ion Beam Sputtering 2 o 5 Film Refractive Index Modification:

[0050] 1) Si substrate with ultra-smooth surface, surface roughness ~0.3nm, size Φ40×0.30mm, prepared by ion beam sputtering deposition method 2 o 5 film;

[0051] 2) Ion beam sputtering deposition of Ta 2 o 5 The film adopts high-purity metal Ta target material, the purity is ≥99.95%, and the vacuum degree of the back is better than 1.0×10 -3 P, the ion beam voltage is 1250V, the ion beam current is 600mA, the oxygen flow rate is 25sccm, and the deposition time is 1h;

[0052] 3) Prepared Ta 2 o 5 The film is placed in a quartz petri dish, and processed in an Ar atmosphere of a hot isostatic pressing device, with a pressure of 50Mpa, a temperature of 300°C, and a processing time of 16 hours;

[0053] 4) Use an ellipsometer to measure the reflection ellipsometric parameters Ψ(λ) and Δ(λ) of the silica film, set the measurement wavelength range to 300nm-800nm, the measurement step...

Embodiment 3

[0056] Preparation of SiO by Ion Beam Sputtering 2 Film Refractive Index Modification:

[0057] 1) Si substrate with ultra-smooth surface, surface roughness ~0.3nm, size Φ40×0.30mm, SiO2 thin film prepared by ion beam sputtering deposition method;

[0058] 2) SiO deposited by ion beam sputtering 2 The film adopts high-purity ultraviolet fused silica target material, the purity is ≥99.995%, and the vacuum degree of the back and the bottom is better than 1.0×10 -3 P, the ion beam voltage is 1250V, the ion beam current is 600mA, the oxygen flow rate is 25sccm, and the deposition time is 1h;

[0059] 3) Prepared SiO 2 The film is placed in a quartz petri dish, and processed in an Ar atmosphere of a hot isostatic pressing device, with a pressure of 50Mpa, a temperature of 300°C, and a processing time of 16 hours;

[0060] 4) Use an ellipsometer to measure the reflection ellipsometric parameters Ψ(λ) and Δ(λ) of the silica film, set the measurement wavelength range to 400nm-800n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| angle of incidence | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com