Method for reducing refractive index of ceramic oxide optical thin film

A technology of ceramic oxide and optical thin film, which is applied in optics, optical components, sputtering coating, etc., to achieve the effect of ensuring lateral uniformity, feasible operation and novel method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

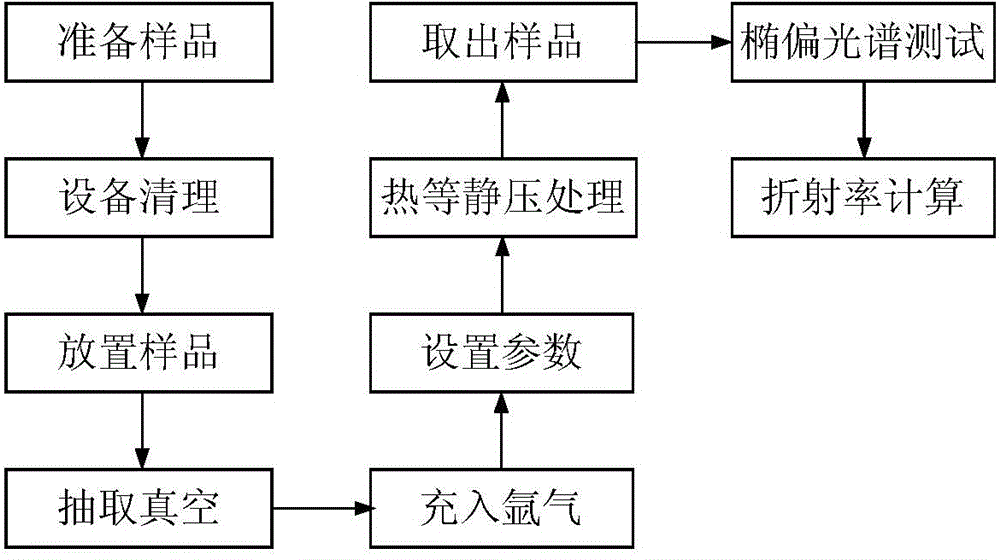

Method used

Image

Examples

Embodiment 1

[0042] Preparation of HfO by Ion Beam Sputtering 2 Film Refractive Index Modification:

[0043] 1) Si substrate with ultra-smooth surface, surface roughness ~0.3nm, size Φ40×0.30mm, HfO prepared by ion beam sputtering deposition method 2 film;

[0044] 2) Ion beam sputtering deposition of HfO 2 The thin film adopts high-purity metal Hf target material, the purity is ≥99.95%, and the vacuum degree of the back is better than 1.0×10 -3 P, the ion beam voltage is 1250V, the ion beam current is 600mA, the oxygen flow rate is 25sccm, and the deposition time is 1h;

[0045] 3) Prepared HfO 2 The film is placed in a quartz petri dish, and processed in an Ar atmosphere of a hot isostatic pressing device, with a pressure of 50Mpa, a temperature of 300°C, and a processing time of 16 hours;

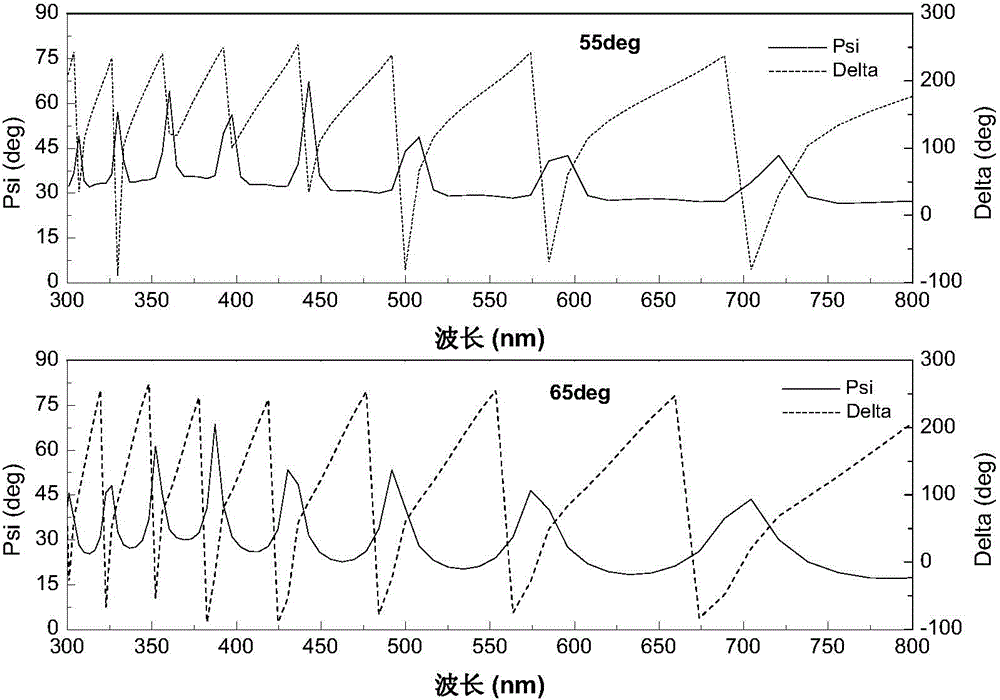

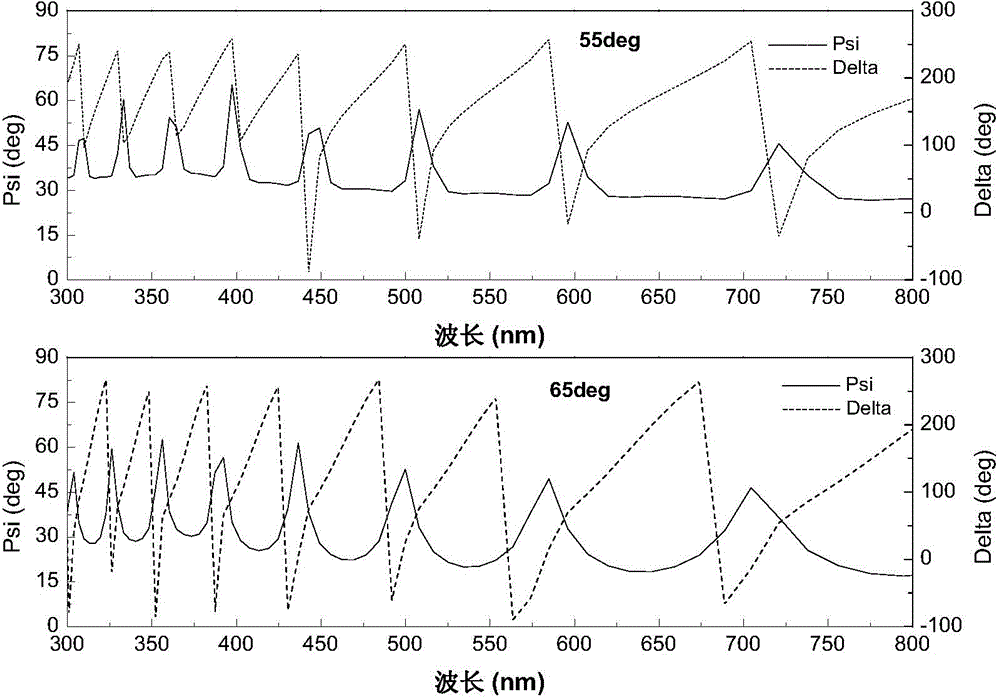

[0046] 4) Use an ellipsometer to measure the reflection ellipsometric parameters Ψ(λ) and Δ(λ) of the silica film, set the measurement wavelength range to 300nm-800nm, the measurement step size ...

Embodiment 2

[0049] Preparation of Ta by Ion Beam Sputtering 2 o 5 Film Refractive Index Modification:

[0050] 1) Si substrate with ultra-smooth surface, surface roughness ~0.3nm, size Φ40×0.30mm, prepared by ion beam sputtering deposition method 2 o 5 film;

[0051] 2) Ion beam sputtering deposition of Ta 2 o 5 The film adopts high-purity metal Ta target material, the purity is ≥99.95%, and the vacuum degree of the back is better than 1.0×10 -3 P, the ion beam voltage is 1250V, the ion beam current is 600mA, the oxygen flow rate is 25sccm, and the deposition time is 1h;

[0052] 3) Prepared Ta 2 o 5 The film is placed in a quartz petri dish, and processed in an Ar atmosphere of a hot isostatic pressing device, with a pressure of 50Mpa, a temperature of 300°C, and a processing time of 16 hours;

[0053] 4) Use an ellipsometer to measure the reflection ellipsometric parameters Ψ(λ) and Δ(λ) of the silica film, set the measurement wavelength range to 300nm-800nm, the measurement step...

Embodiment 3

[0056] Preparation of SiO by Ion Beam Sputtering 2 Film Refractive Index Modification:

[0057] 1) Si substrate with ultra-smooth surface, surface roughness ~0.3nm, size Φ40×0.30mm, SiO2 thin film prepared by ion beam sputtering deposition method;

[0058] 2) SiO deposited by ion beam sputtering 2 The film adopts high-purity ultraviolet fused silica target material, the purity is ≥99.995%, and the vacuum degree of the back and the bottom is better than 1.0×10 -3 P, the ion beam voltage is 1250V, the ion beam current is 600mA, the oxygen flow rate is 25sccm, and the deposition time is 1h;

[0059] 3) Prepared SiO 2 The film is placed in a quartz petri dish, and processed in an Ar atmosphere of a hot isostatic pressing device, with a pressure of 50Mpa, a temperature of 300°C, and a processing time of 16 hours;

[0060] 4) Use an ellipsometer to measure the reflection ellipsometric parameters Ψ(λ) and Δ(λ) of the silica film, set the measurement wavelength range to 400nm-800n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| angle of incidence | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com