Cleaning device for textile cloth

A cleaning device and a technology for textile fabrics, which are applied in the direction of textile material processing equipment configuration, textile material processing, and textile material drum processing, can solve the problems of textile cloth cleaning, textile cloth cleaning is not clean, low efficiency, etc., to achieve overall Simple structure, strong practicability, avoid the effect of folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

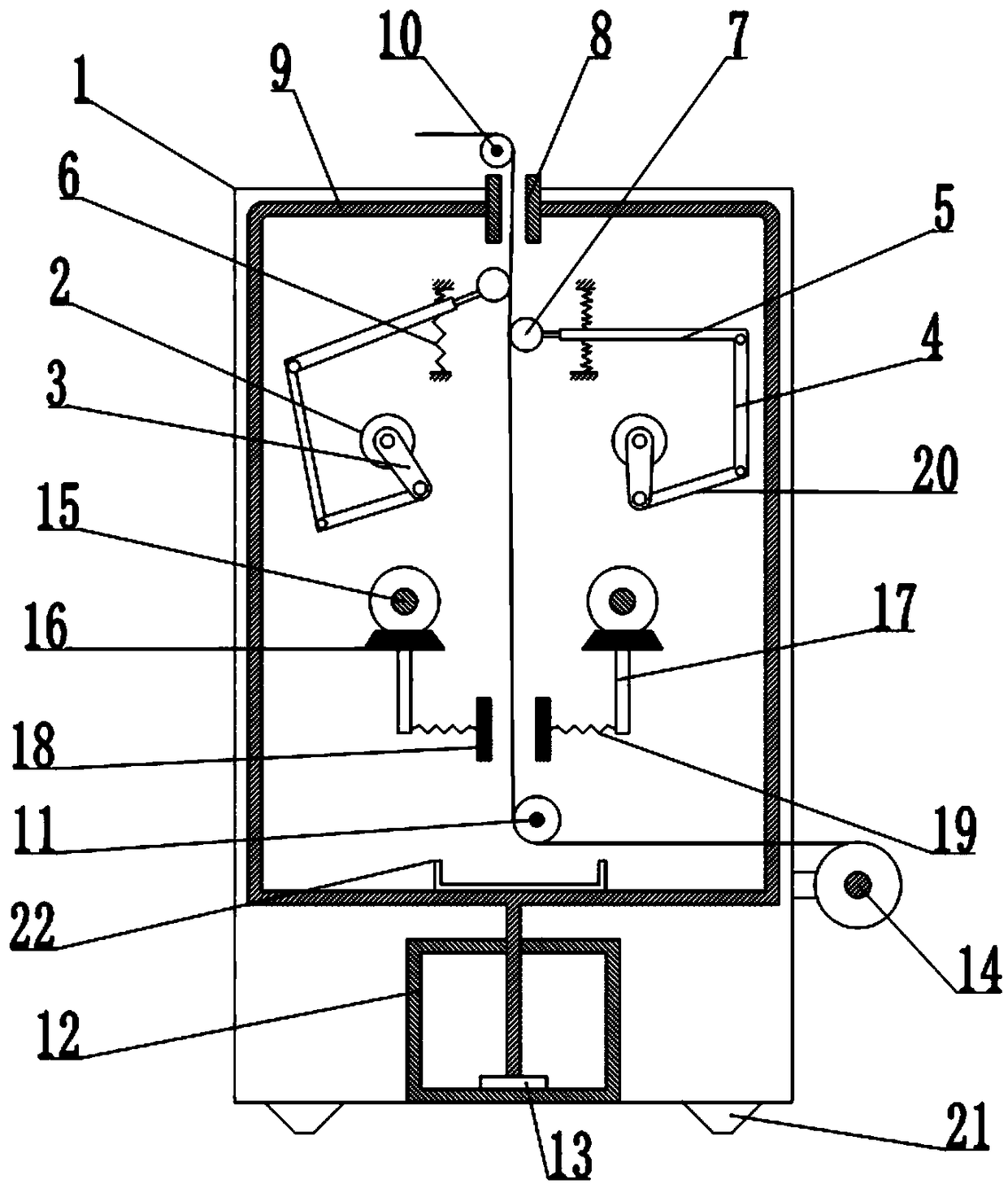

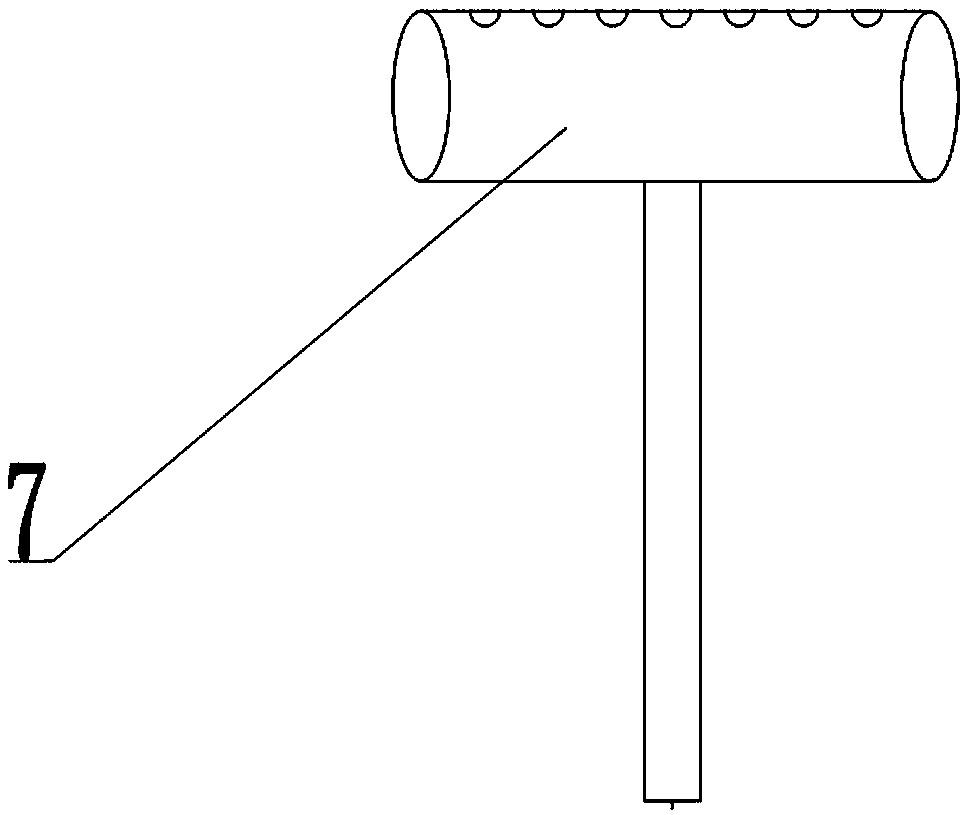

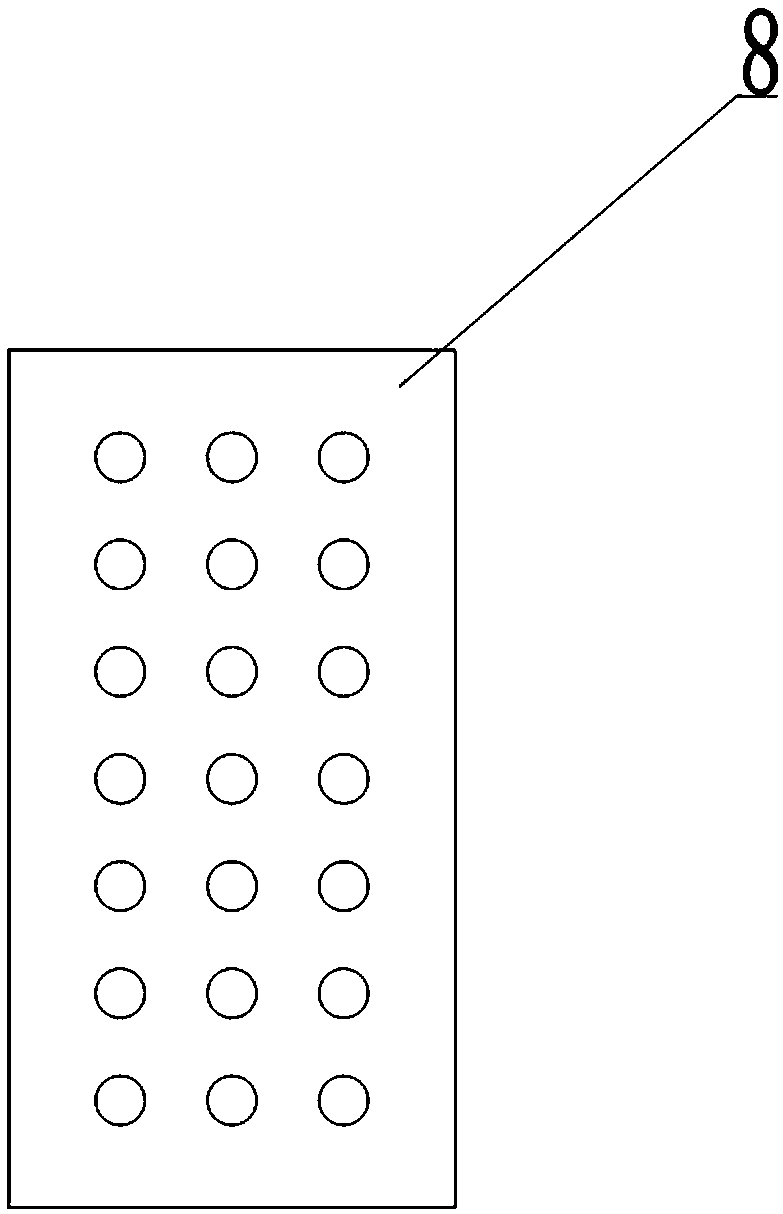

[0019] The reference signs in the drawings of the description include: box 1, motor 2, rocker 3, vertical bar 4, cross bar 5, extension spring 6, water spray brush 7, shower 8, water pipe 9, first roller 10, Second roller 11, cleaning box 12, water pump 13, collection cylinder 14, first bevel gear 15, second bevel gear 16, rotating rod 17, magnet block 18, spring 19, connecting rod 20, foot 21, waste water bucket 22 .

[0020] The embodiment is basically as attached Figure 1 to Figure 3 Shown: a textile cloth cleaning device, comprising a box body 1, a water pipe 9 is fixedly installed on the side wall of the box body 1, a first roller 10 is rotatably connected to the top of the box body 1, and a feeding port is opened on the top of the box body 1, and the feeding port A shower 8 is fixedly connected to the box body 1 on both sides of the mouth, and the shower 8 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com