Self-washing pile shoe for pile leg and washing method

A spud shoe and pile leg technology, which is applied in the field of self-piercing spud shoes, can solve problems such as failure of the flushing pile system, blockage of branch pipes and main circuit pipelines, and increased difficulty in plugging and unplugging, so as to achieve good compression resistance and reduce pressure loss , easy to pull out effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] Those skilled in the art can understand that unless otherwise defined, all terms used herein, including technical terms and directional terms, have the same meanings as commonly understood by those of ordinary skill in the art to which the present invention belongs.

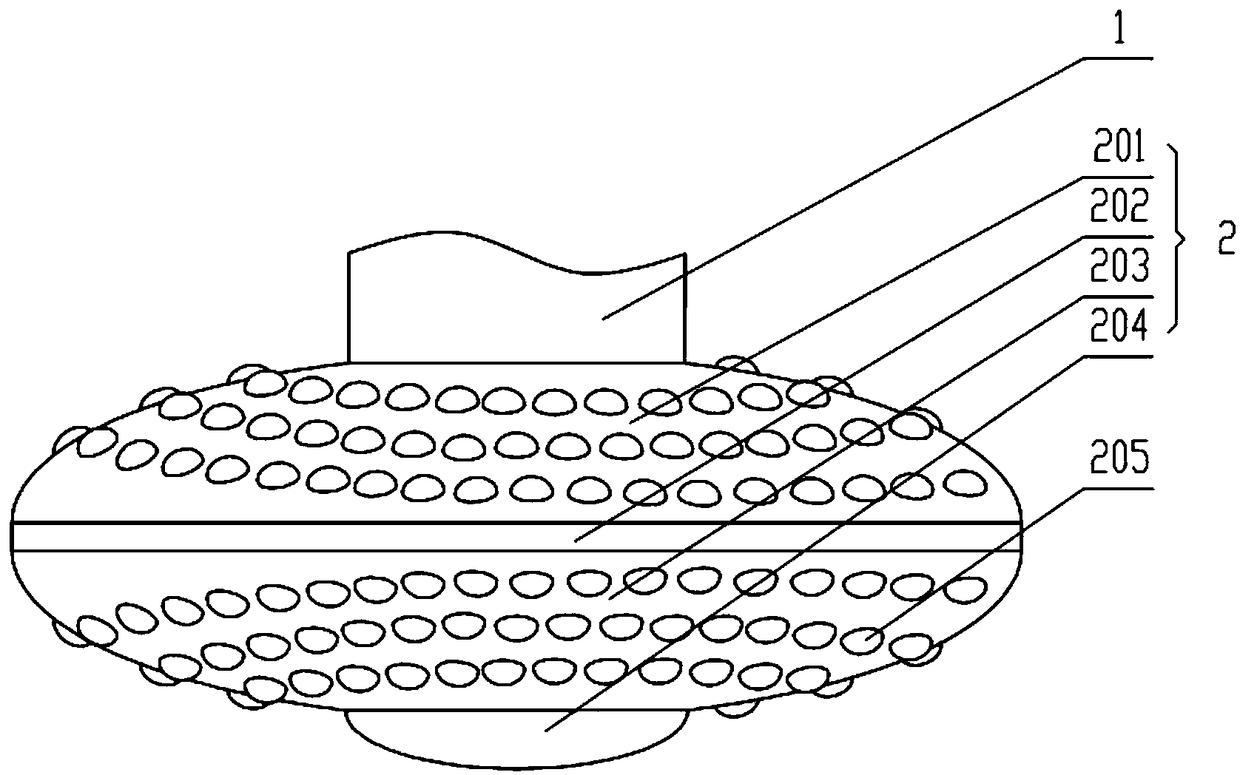

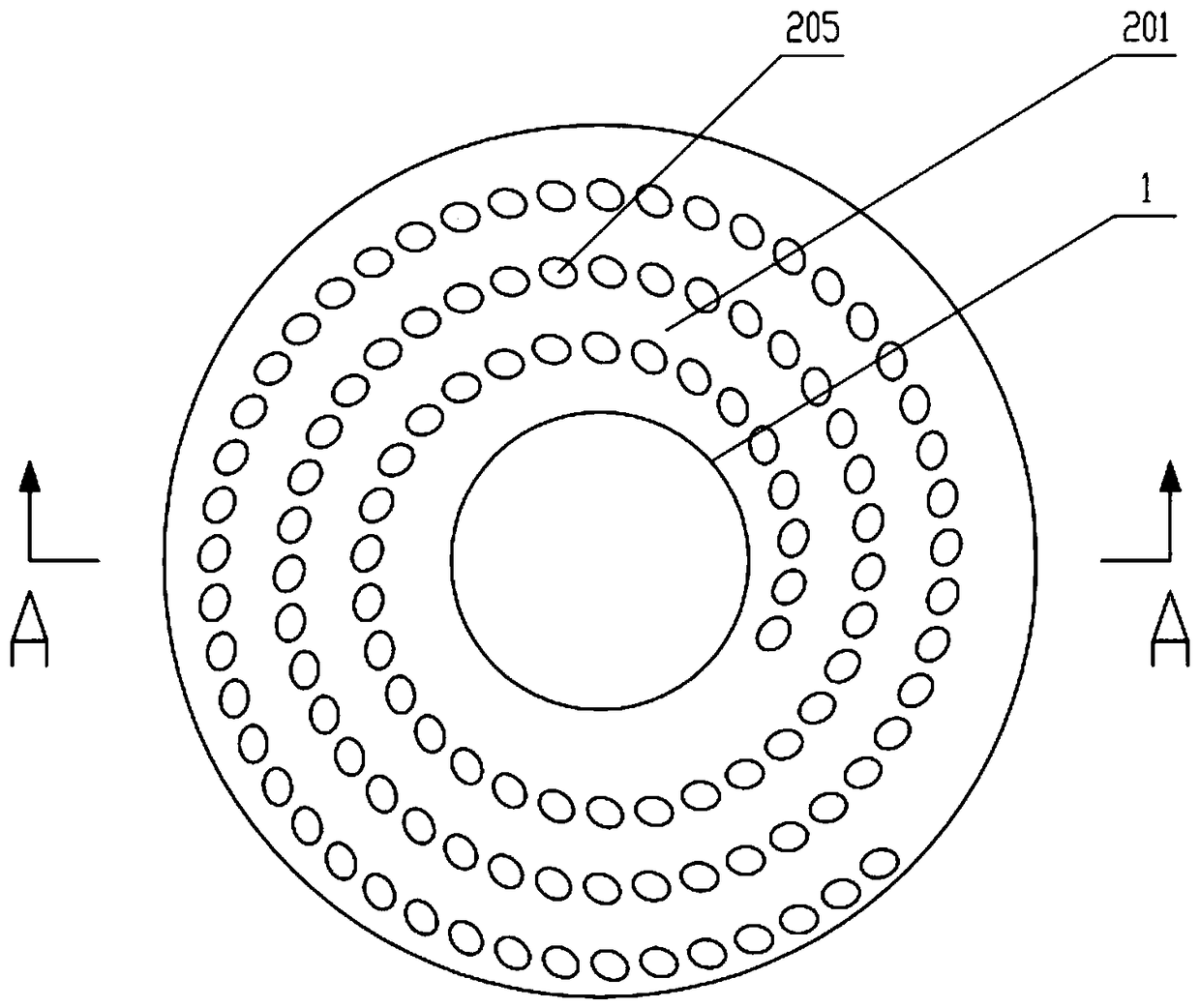

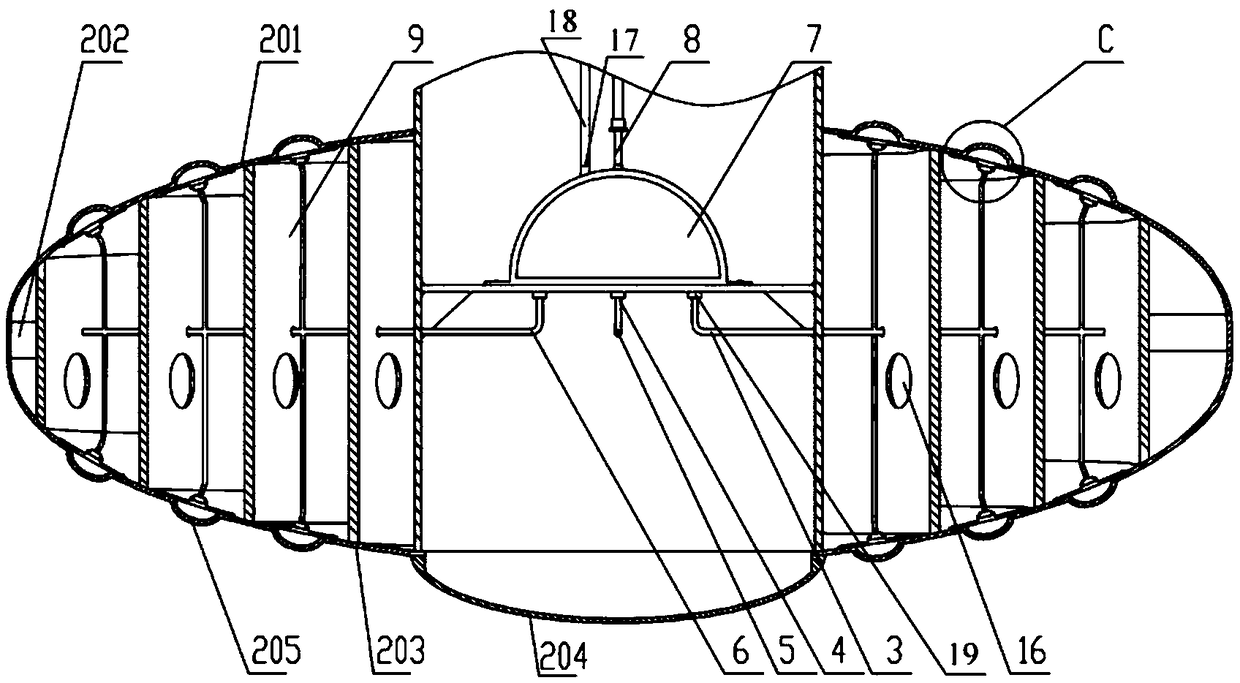

[0028] Such as Figure 1 to Figure 3 As shown, a self-elevating platform pile pile shoe includes a pile shoe 2 welded at the bottom of the pile leg 1, and the pile shoe 2 includes an upper pile shoe 201, a transition plate 202, a lower pile shoe 203 and The positioning plate 204, the upper spud can 201 and the lower spud can 203 are symmetrical up and down along the transition plate 202, the inside of the upper spud can 201 and the lower spud can 203 are provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com