Subway superlarge section tunnel underground excavation support replacement and main body structure construction method

A technology of super large section and main structure, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as hidden safety hazards, and achieve the effect of improving pouring quality, good integrity and reducing erection height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

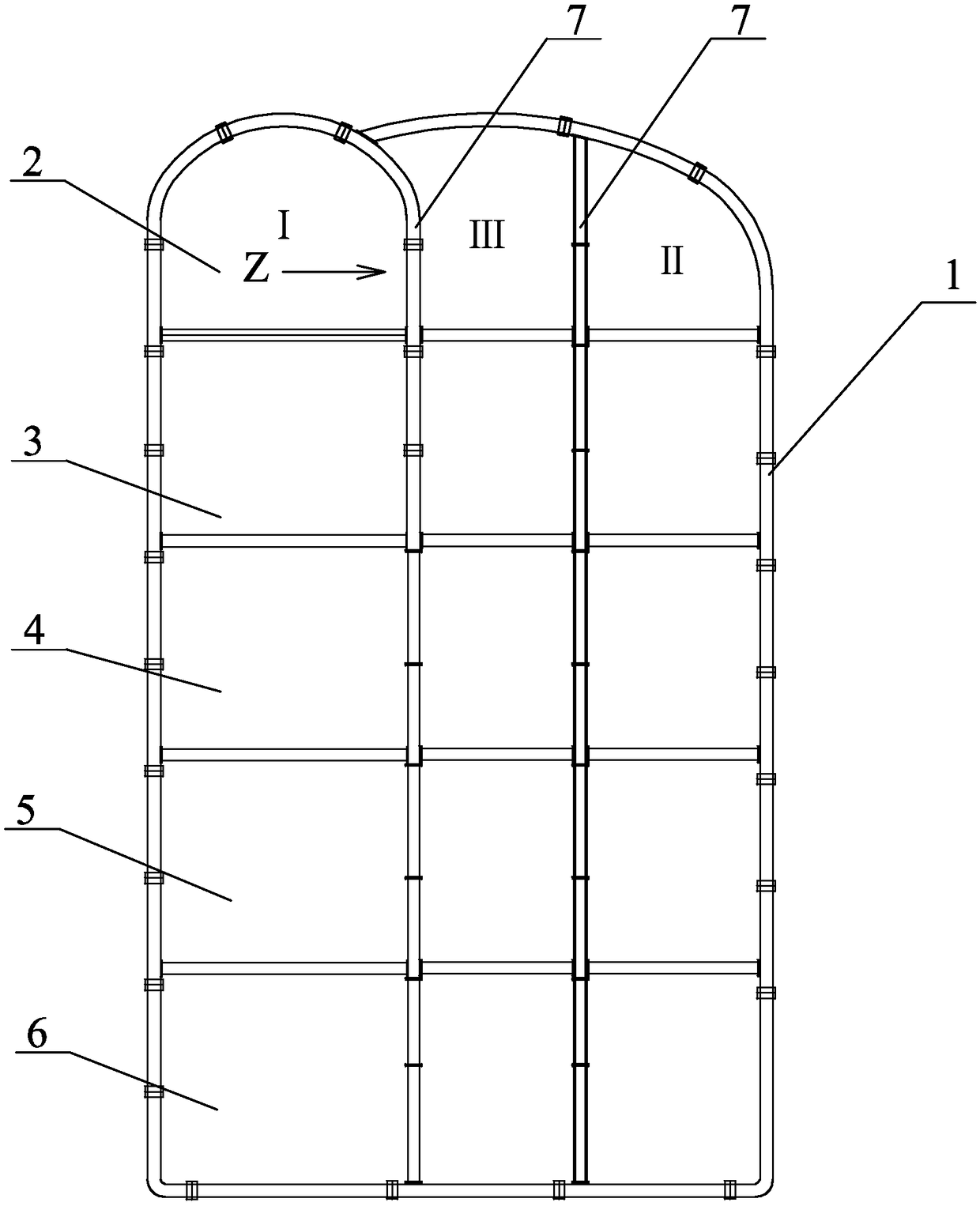

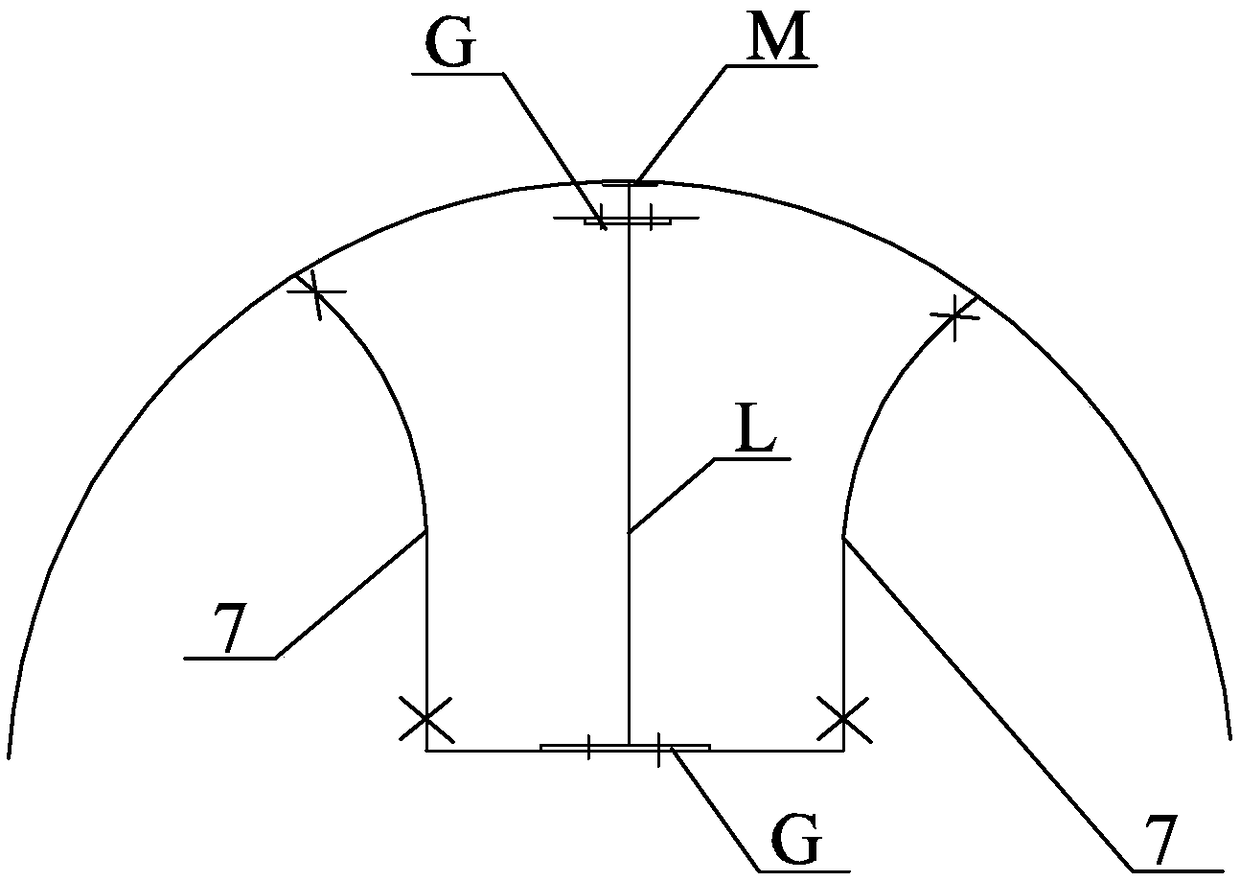

[0046] Specific implementation mode one: combine Figure 1 to Figure 7 Illustrate this embodiment, the construction method of a kind of submerged excavation of subway super-large-section tunnel submerged support and main structure of this embodiment, the main structure of underground excavation of subway super-large-section tunnel adopts the method of construction, and its implementation process is:

[0047] Step 1: After the initial support of the excavation and the back grouting are completed, the concrete cushion is poured;

[0048] Adopt the method of excavation and support in layers and divisions, excavate and support in layers from top to bottom, perform grouting behind the initial support, and pour a concrete cushion to form the foundation pit support structure 1;

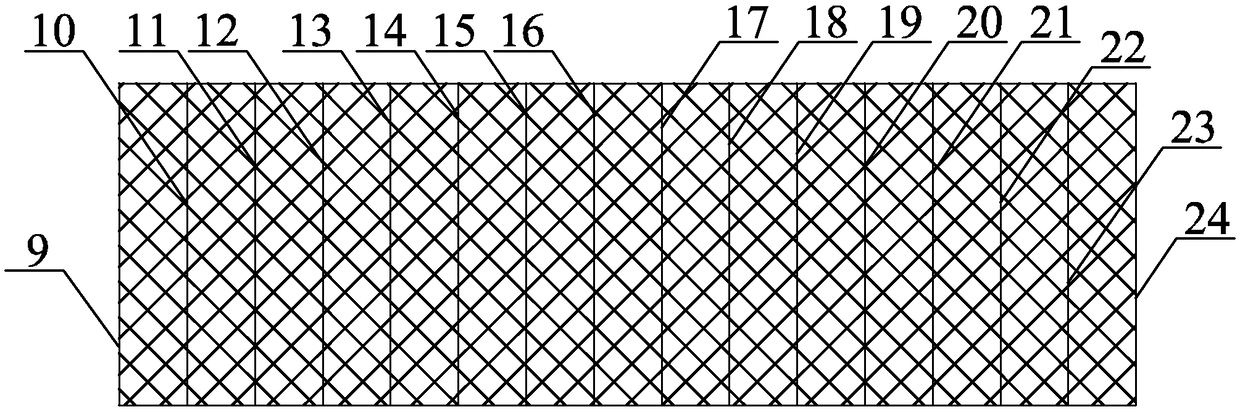

[0049] Step 2: Remove the concrete and steel mesh 8, and remove part of the I-beam for the first time;

[0050] The foundation pit support structure 1 is the fifth layer 2, the fourth layer 3, the third lay...

specific Embodiment approach 2

[0072] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the sequence of excavation and support in Step 1 of this embodiment is: excavation and support in layers from top to bottom, with the same layer first on both sides and then in the middle to complete all the excavation and support work. With such setting, the efficiency of excavation and support is improved, and safety is ensured. The other components and connections are the same as those of the first embodiment.

specific Embodiment approach 3

[0073] Specific implementation mode three: combination figure 2 To describe this embodiment, the distance between two adjacent I-beams exposed on the partition wall 7 from the first floor to the fifth floor of this embodiment is 0.5m. With such a setting, the spacing is reasonable, which is convenient to ensure the safety performance of the support. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com