Universal adjustable type carbon black conveying pipe joint flange

A joint flange and conveying pipe technology, which is applied in the field of universal adjustable carbon black conveying pipe joint flanges, can solve the problems of difficulty in adapting to flexible arrangement of conveying pipelines, increased losses along the way, and increased pipeline costs, etc. The effect of flexible limit, easy standardization and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

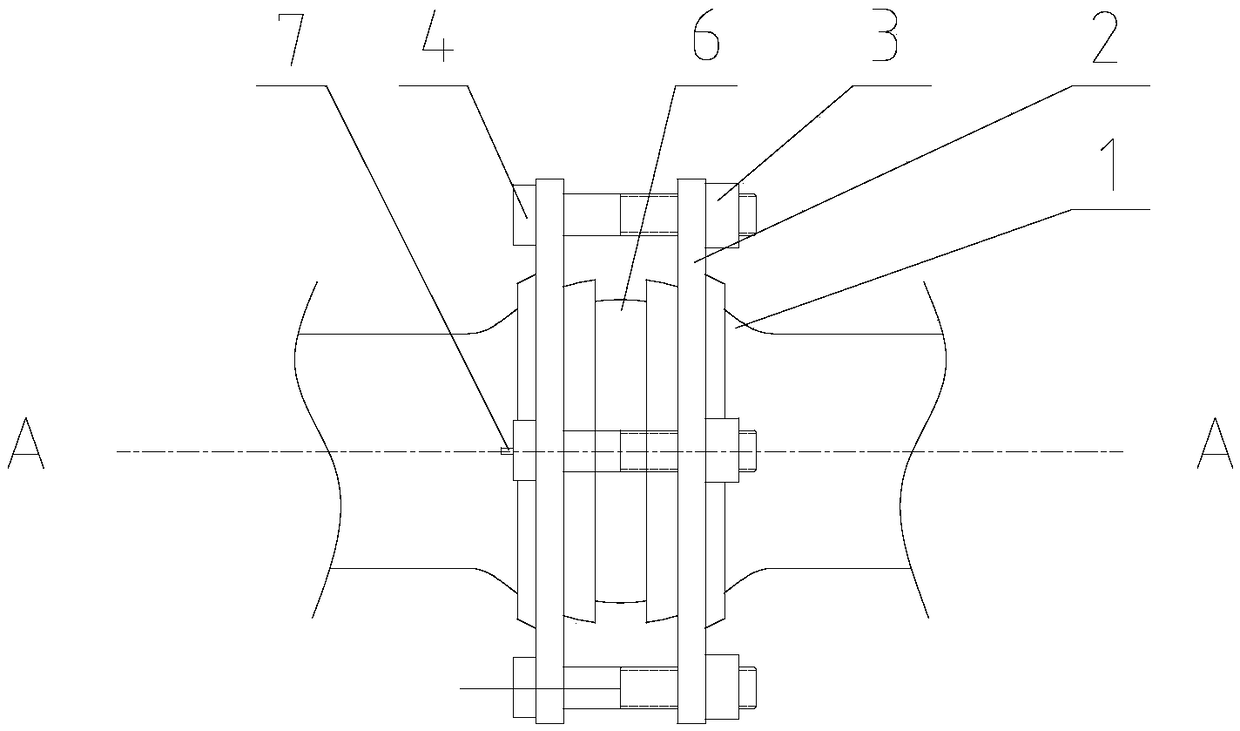

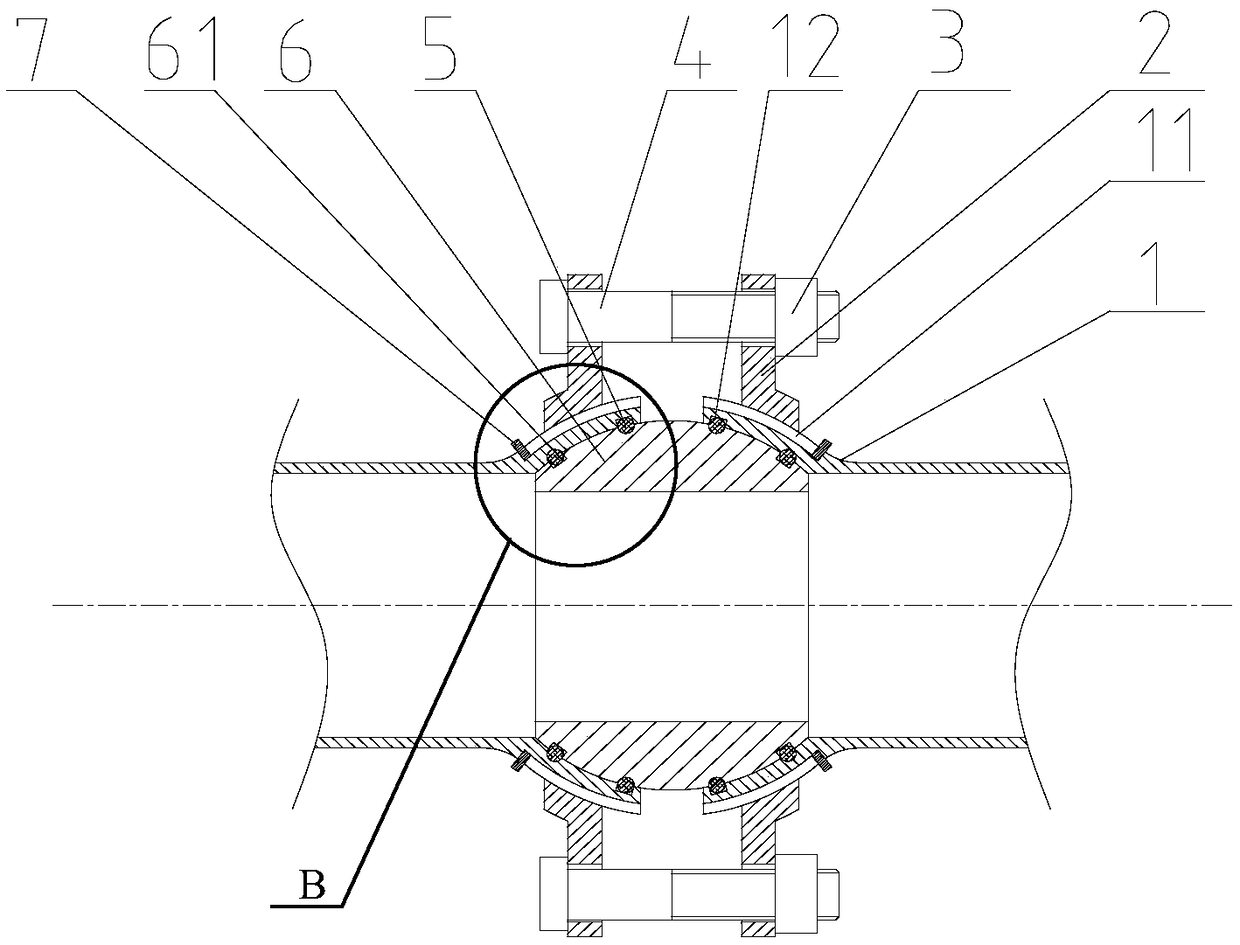

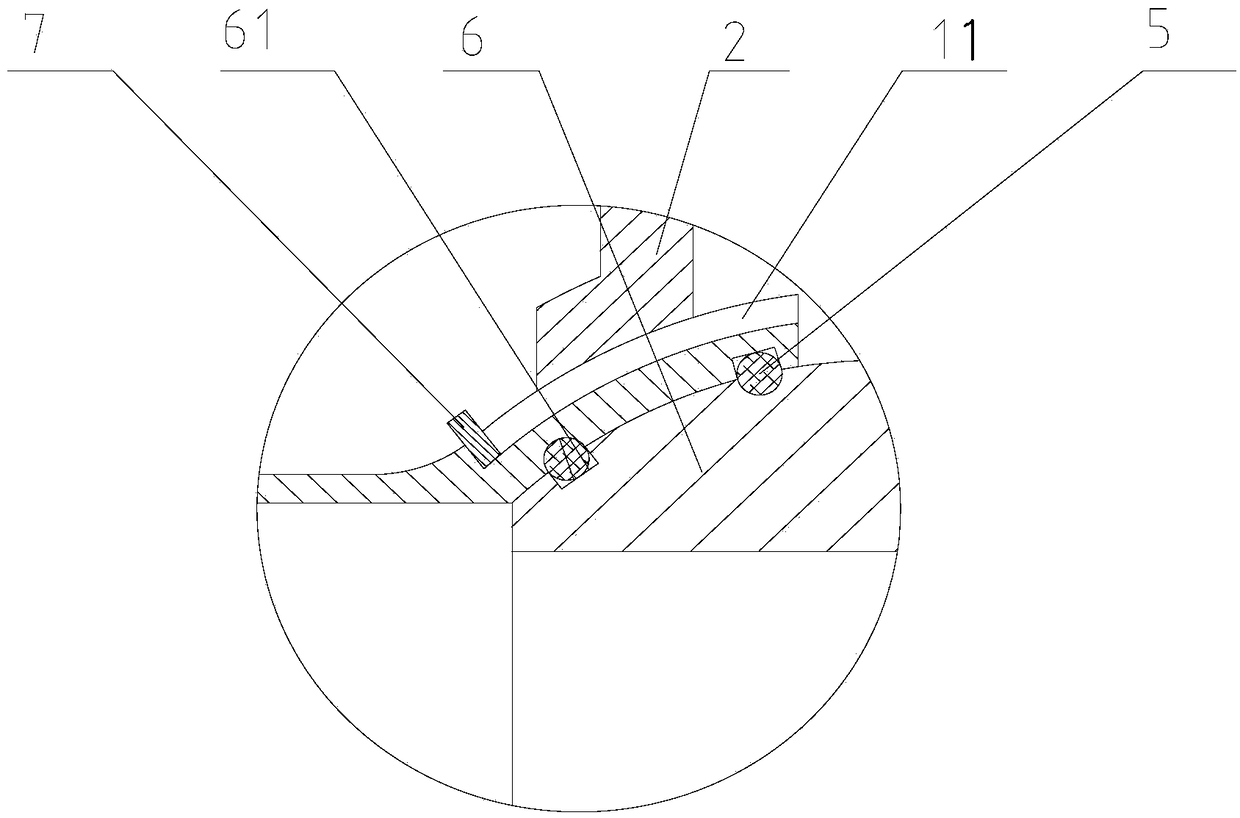

[0023] Such as Figures 1 to 4 As shown, a universally adjustable carbon black delivery pipe joint flange of the present invention is composed of a connecting flange 1, an active flange 2, a nut 3, a bolt 4, a sealing ring 5, a spherical core 6 and a limit pin 7 .

[0024] There are two connecting flanges 1, and the connecting flanges 1 are hollow to form a flow channel. The end of each connecting flange 1 is provided with a spherical portion, and the connecting flange 1 is respectively arranged on both sides of the spherical core 6 , and the inner side of the spherical portion is in contact with the spherical core 6 . After the connecting flanges 1 on both sides pass through the active flanges 2 on each side, they are further tightened and connected by the nuts 3 and bolts 4 on the active flanges 2 on both sides, so that the pipelines on both sides a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com