Looseness detecting device for shield cutter head detachable cutter

A technology of shield cutter head and detection device, which is applied in the direction of measuring device, testing of machine/structural components, measuring fluid pressure, etc., can solve the problems of damage to the screw machine in the soil bin, affecting the disassembly and assembly work, and bending of bolts. , to ensure the construction efficiency, prevent the tool from falling off, and reduce the probability of secondary damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

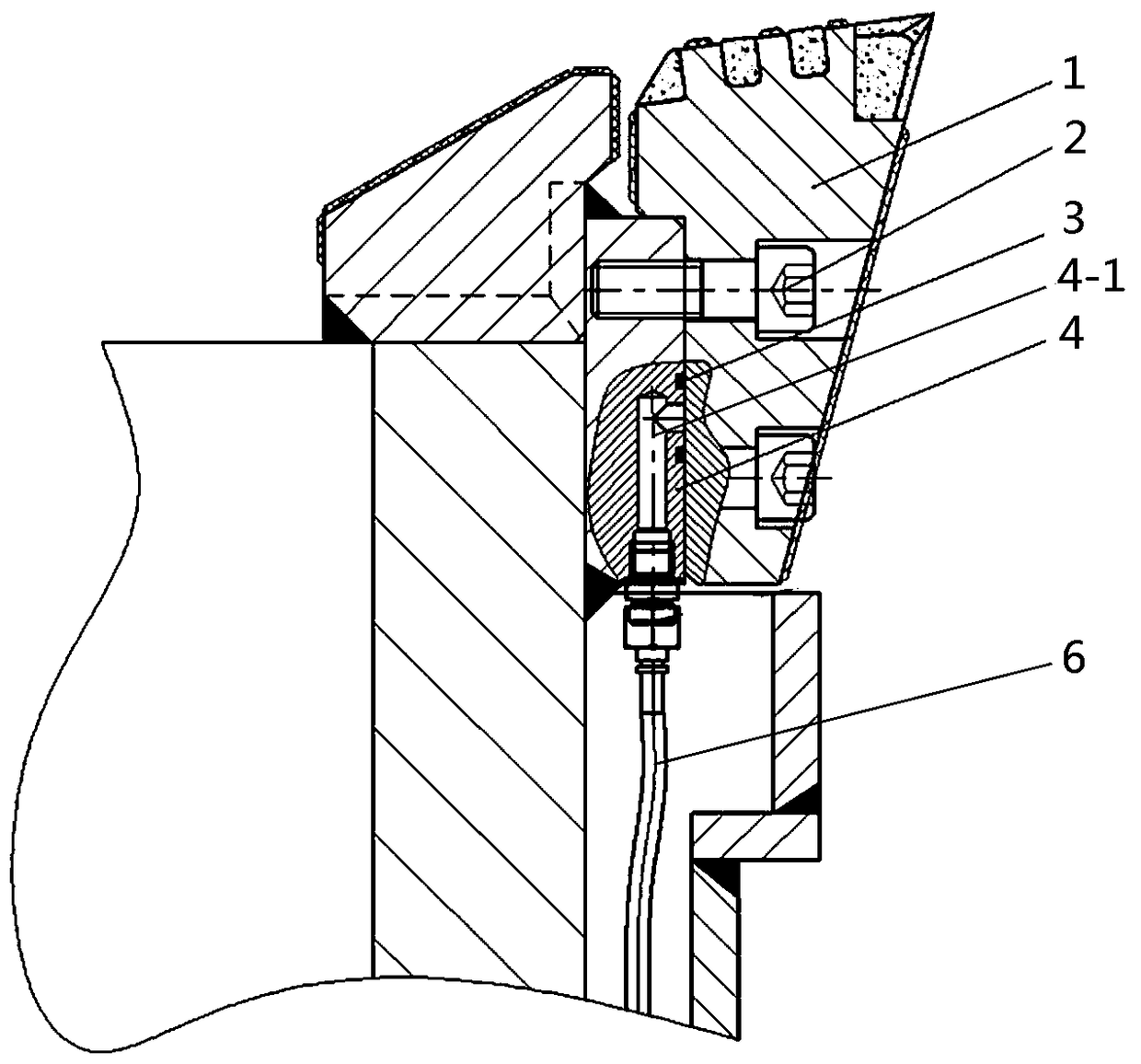

[0014] Embodiment 1, the detachable tool loose detection device of the shield cutter head, such as figure 1 As shown, it includes the knife seat 4 and the scraper 1 set on the knife seat 4 through the bolt 2, the oil hole 4-1 leading to the installation surface of the scraper 1 is arranged in the knife seat 4, and the oil hole 4-1 leads to the knife installation surface There is an O-ring seal 3 on the outer periphery of the port. The O-ring 3 can not only ensure the sealing connection between the knife seat 4 and the scraper 1, but also the O-ring is an elastic element. When changing, the seal will not fail, and the precise design can effectively avoid false detection and false alarm.

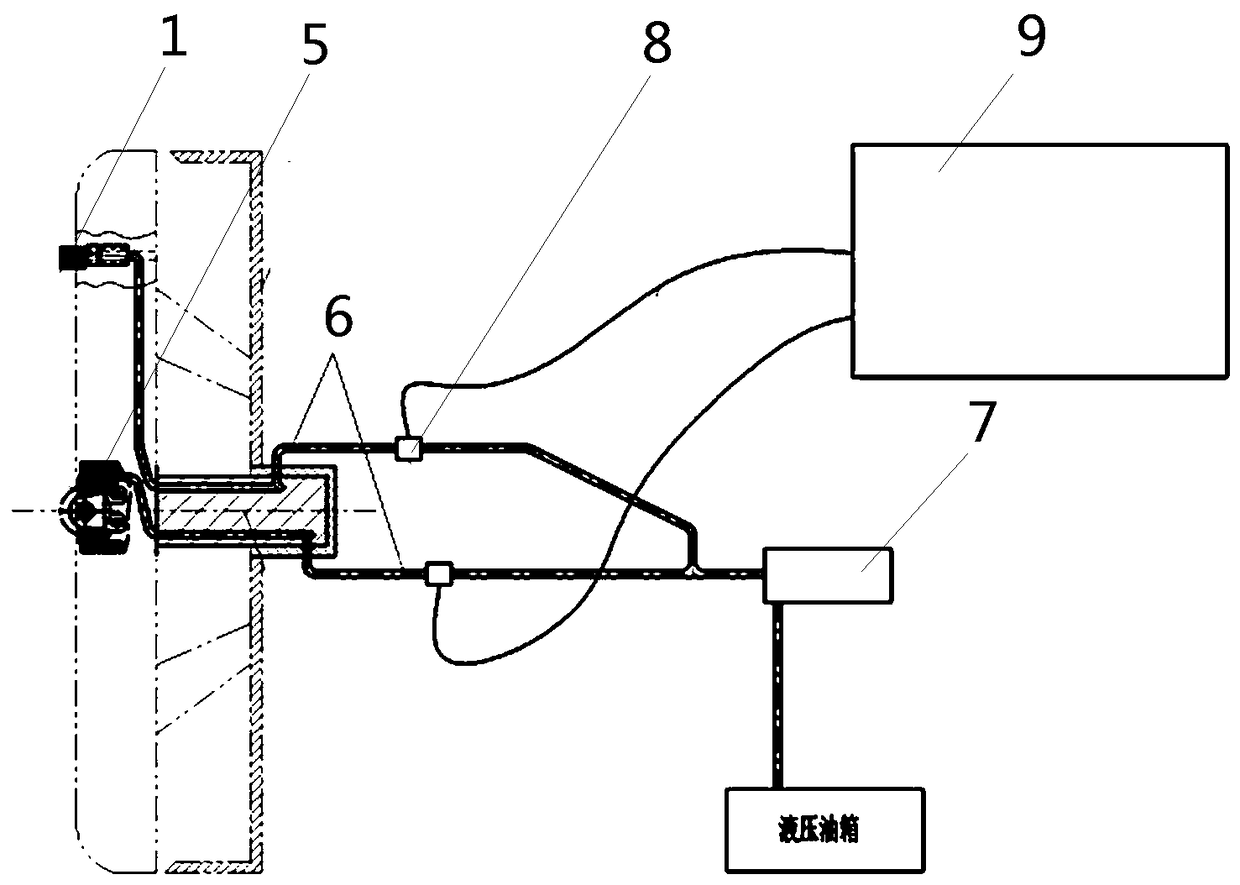

[0015] Such as image 3 As shown, the other port of the oil hole 4-1 is connected to a pressure detection system, and the pressure monitoring system includes an oil pipe 6, a hydraulic pump 7, and a pressure sensor 8. The other end of the oil hole 4-1 connects with the oil pipe 6 and The hyd...

Embodiment 2

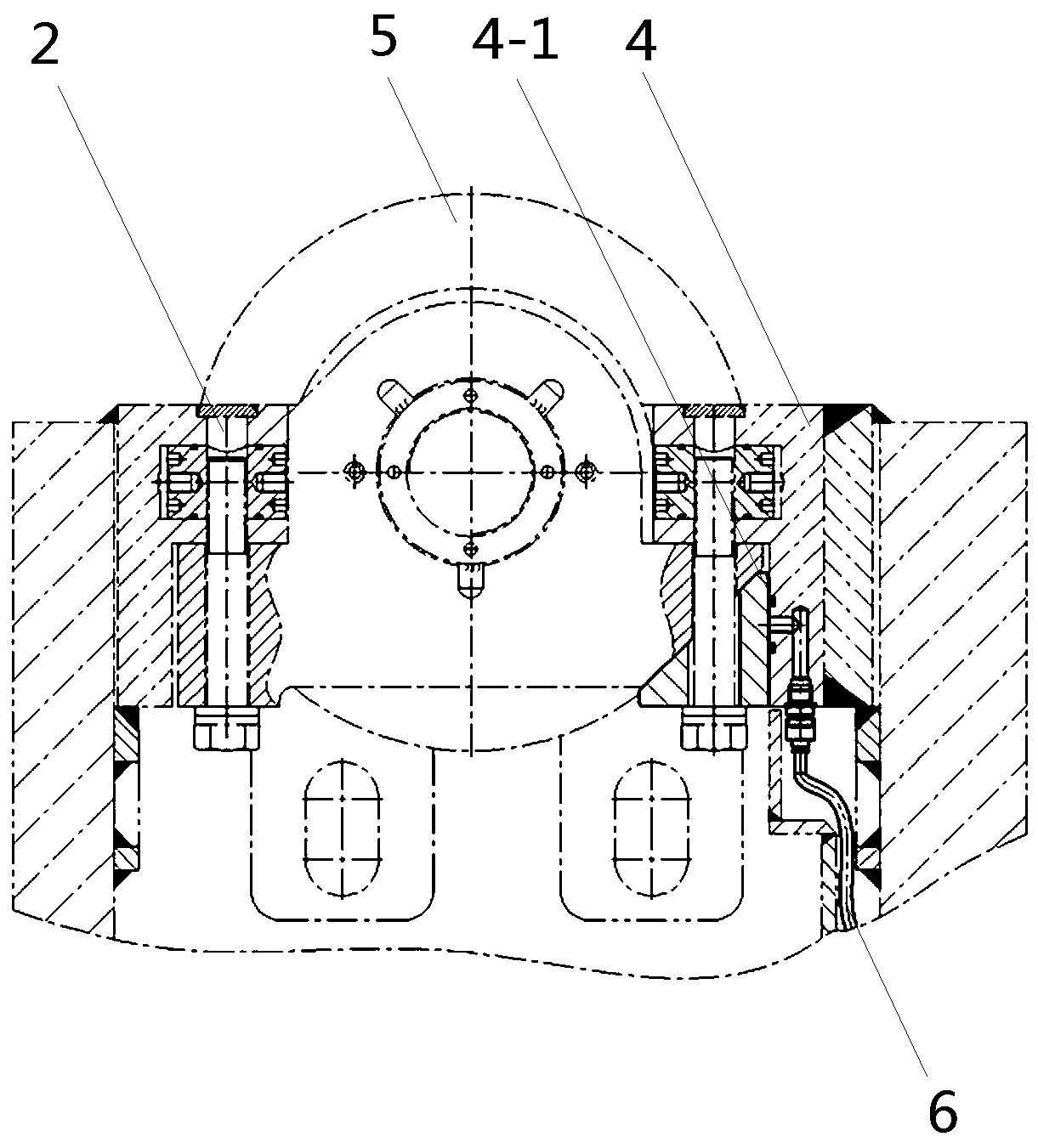

[0017] Embodiment 2, a detachable tool loose detection device for the shield cutter head, such as figure 2 As shown, the scraper 1 in Embodiment 1 can be the hob 5 of the shield machine, and the other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com