Intelligent gasket with anti-loosening function for monitoring bolt fastening state and monitoring method

A technology of bolts and functions, which is applied in the field of fastener connection status monitoring, can solve the problems of difficult wide application, complicated installation, low precision, etc., and achieve the effect of wide application conditions, exquisite structure and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

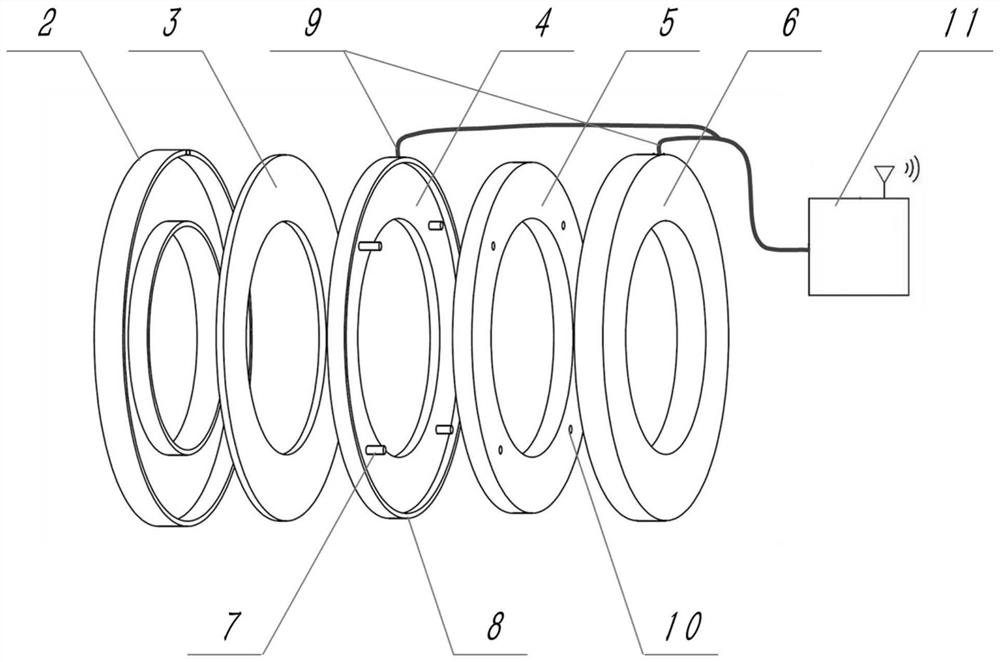

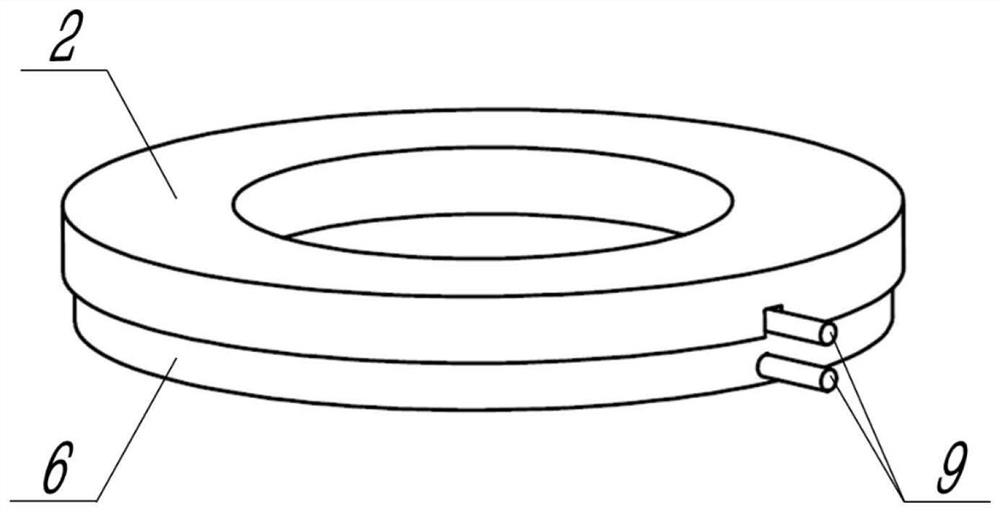

[0037] Such as figure 1 As shown, the present invention is a smart washer with anti-loosening function for monitoring the fastening state of bolts. The smart washer 1 includes a metal upper sheet 2, an insulating sheet 3, a monitoring sheet 4, a superelastic sheet 5 and a metal lower sheet stacked in sequence. Sheet 6, metal upper sheet 2, insulating sheet 3, monitoring sheet 4, superelastic sheet 5 and metal lower sheet 6 all have middle holes for bolts to pass through.

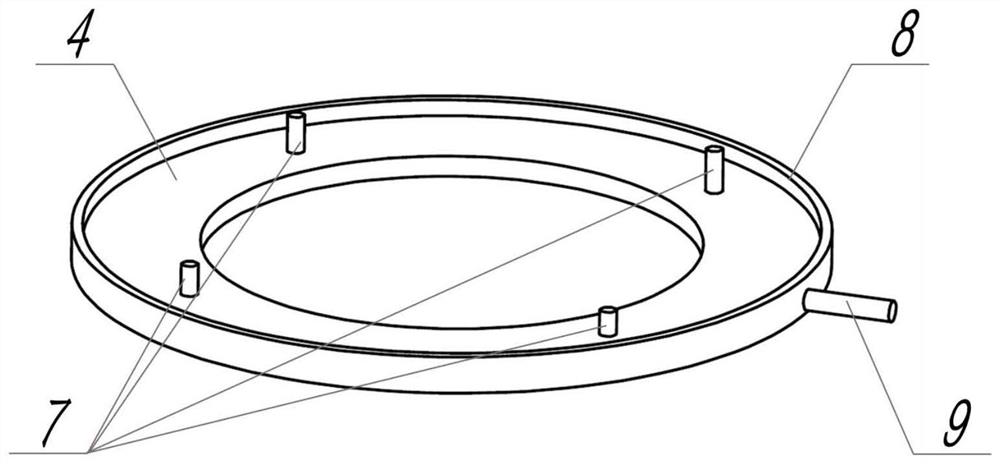

[0038] Wherein, the outer edge of the bottom surface of the monitoring sheet 4 is provided with an annular limit boss 8, and the bottom surface of the monitoring sheet 4 is provided with a number of downwardly protruding metal contacts 7 with different lengths. Correspondingly, on the superelastic sheet 5 A number of through guide holes 10 corresponding to the metal contacts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Preload force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com