Method and device for evaluating repair performance of cement-based self-repair material

A technology for repairing materials and evaluation methods, applied in the field of cement-based materials, can solve problems such as single limitation, limited accuracy of crack observers, and inability to observe, and achieves the effects of wide application range, simple test methods, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments.

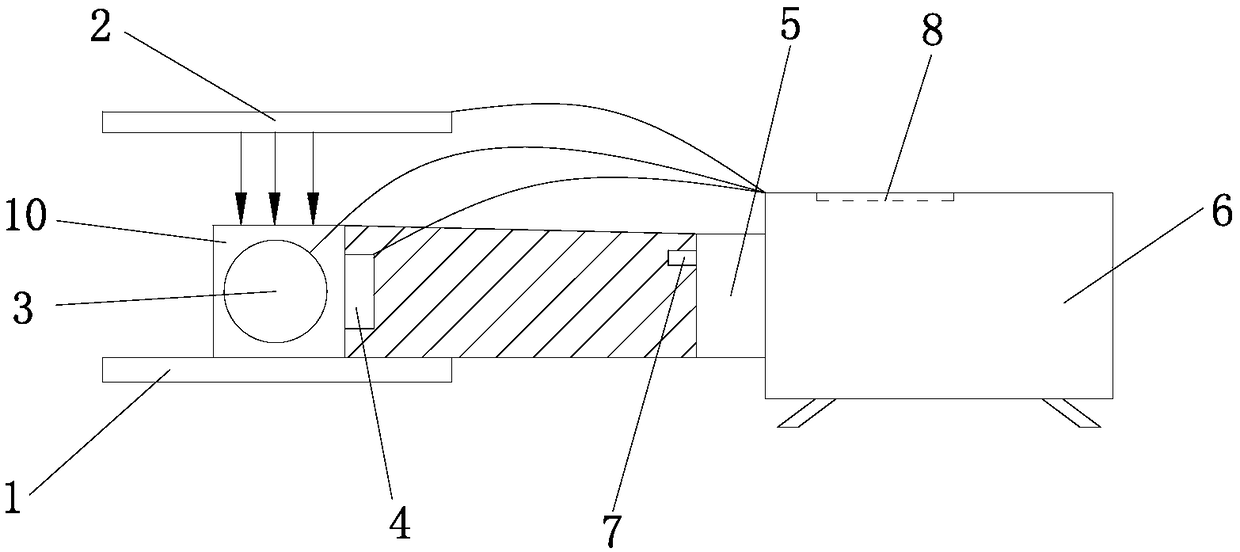

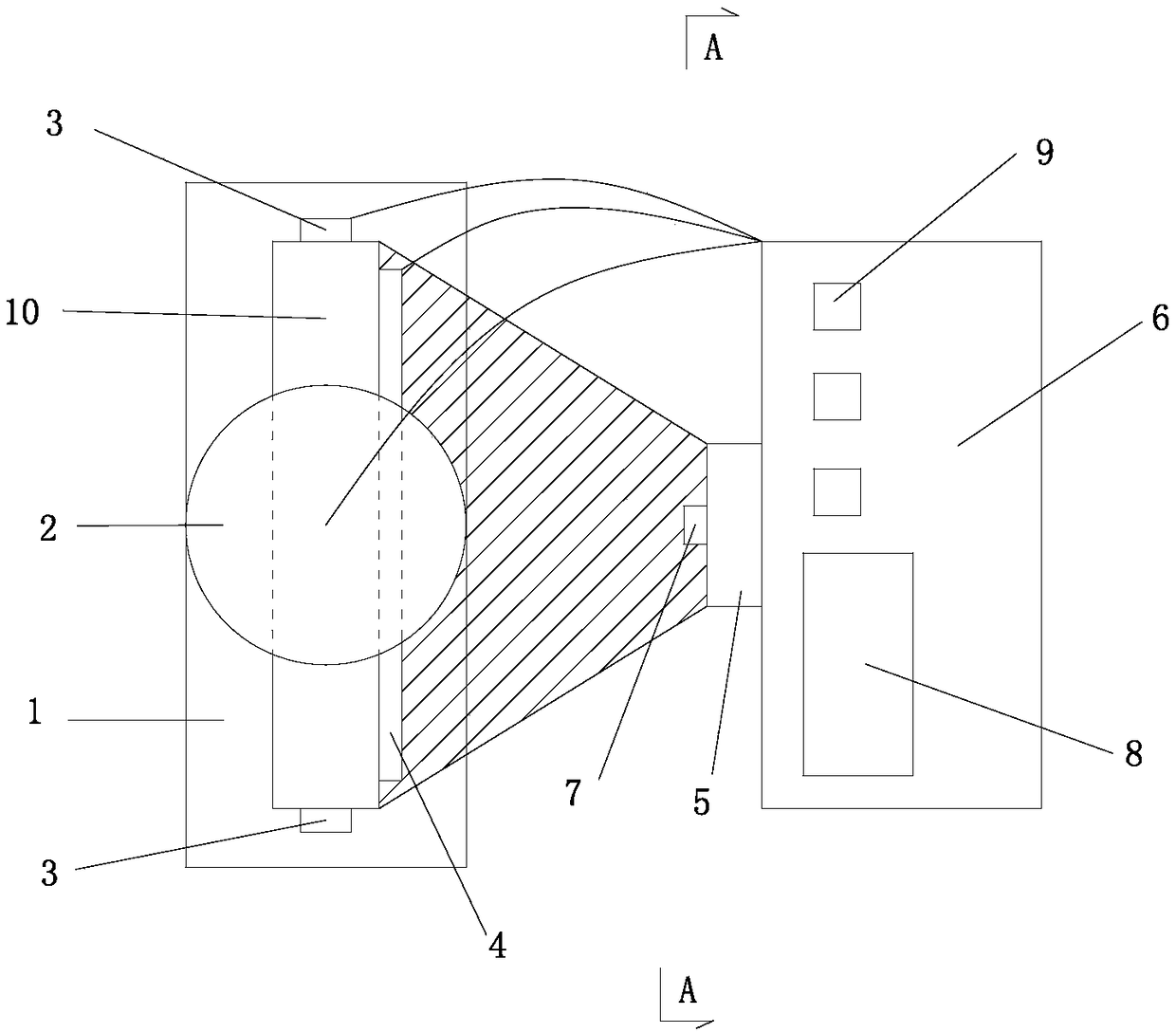

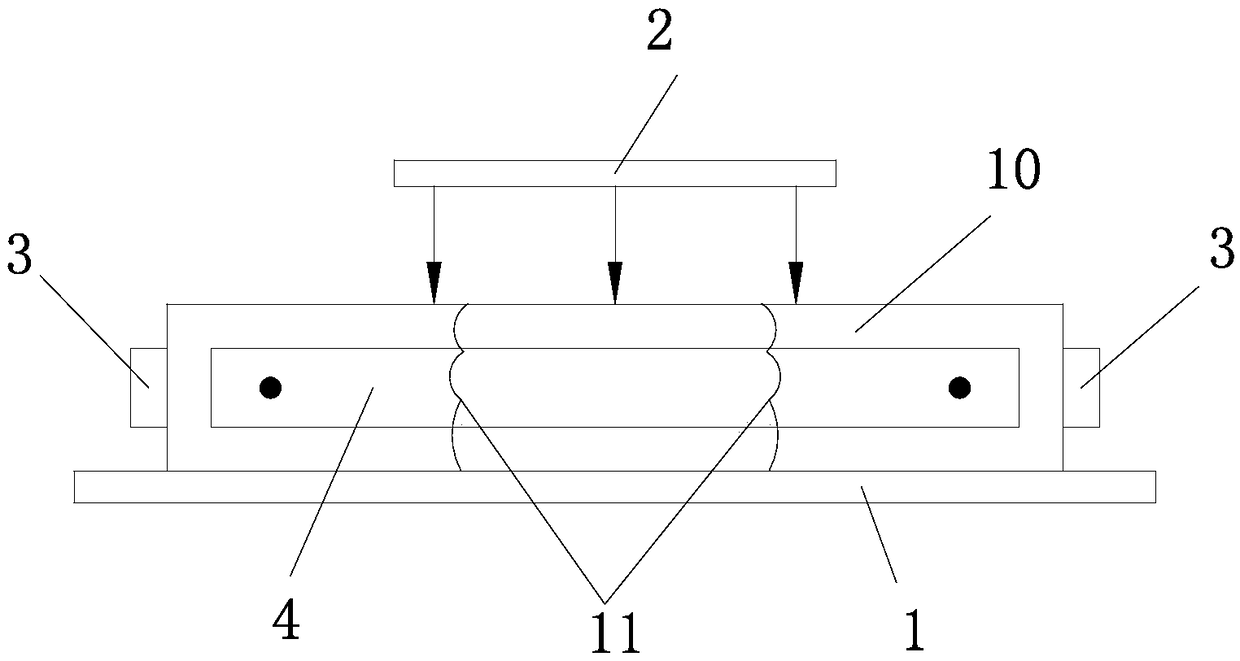

[0031] A kind of evaluation device of cement-based self-repairing material repair performance of the present invention, comprises the base 1 that is used to place cement-based self-repairing material sample 10, and it also comprises:

[0032] Loading device 2, the loading device 2 is used to apply pressure to the cement-based self-repairing material sample 10 after receiving the control signal; the loading device 2 is installed above the cement-based self-repairing material sample 10, The loading rate of the self-healing material to be tested is 0.1-0.5kN / s;

[0033] Ultrasonic generator 3, described ultrasonic generator 3 is used for monitoring the dynamic change of cement-based self-repairing material sample 10 internal crack width, and the data that obtains is sent to automatic analyzer 6; Described ultrasonic generator 3 is installed in cement The axial ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com