A method for obtain continuous gradient porous structure with minimal curved surface

A technology of extremely small surface and acquisition method, applied in the field of porous structure, can solve the problem of single performance, achieve the effect of large design freedom, simple calculation process, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

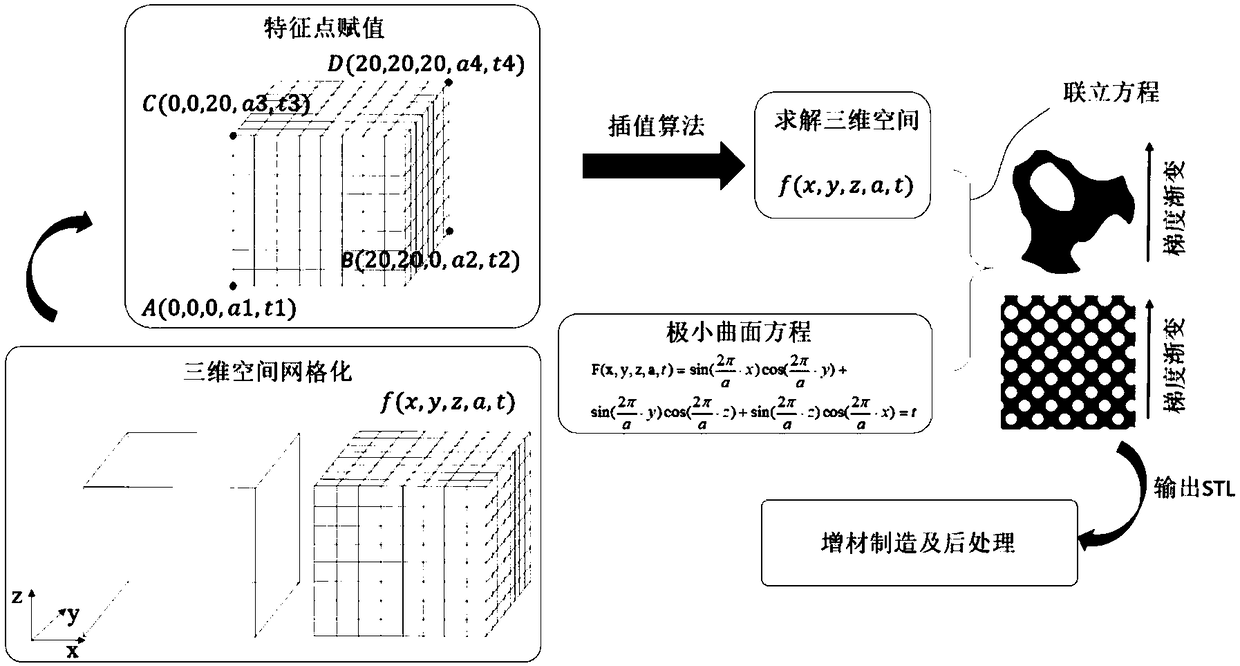

Method used

Image

Examples

example 1

[0034] (1) Establish a spatial range R, where 0≤x≤20, 0≤y≤20, 0≤z≤20, and divide the space into grids, and divide the space with a unit size of 0.05, then each direction of R There are 400 elements, 401 nodes. Establish a spatial function f(x, y, z, a, t), and assign the initial value 0 to a and t of each node.

[0035] (2) Define the characteristic points of the porous structure at different positions in the three-dimensional space: A(0,0,0,2.8,0.05), B(20,20,0,2.8,0.05), C(0,0,20 ,2.25,0.2), D(20,20,20,2.25,0.2).

[0036] (3) According to the feature points defined in step (2), use the interpolation algorithm to obtain the function f value of each point in the middle, such as AC1(0,0,5,2.663,0.0875), AC2(0,0,10, 2.525,0.125), AC3(0,0,15,2.3875,0.1625).

[0037] (4) Carry out the mathematical modeling of Schoen Gyroid porous structure according to f(x, y, z, a, t) at each point in space, b=5 in the formula (1), the value of t at each point can be used in the formula

[00...

example 2

[0042] (1) Establish a spatial range R, where 0≤x≤20, 0≤y≤20, 0≤z≤20, and divide the space into grids, and divide the space with a unit size of 0.05, then each direction of R There are 400 elements, 401 nodes. Establish a spatial function f(x, y, z, a, t), and assign the initial value 0 to a and t of each node.

[0043](2) Define the characteristic points of the porous structure at different positions in the three-dimensional space: A(0,0,0,2.65,0.075), B(20,20,0,2.65,0.075), C(0,0,20 ,2.25,0.2), D(20,20,20,2.25,0.2).

[0044] (3) According to the feature points defined in step (2), use the interpolation algorithm to obtain the function f value of each point in the middle, such as AC1(0,0,5,2.55,0.10625), AC2(0,0,10, 2.45,0.1375), AC3(0,0,15,2.35,0.16875).

[0045] (4) Carry out the mathematical modeling of Schoen Gyroid porous structure according to f(x, y, z, a, t) at each point in space, b=5 in the formula (1), the value of t at each point can be used in the formula

[...

example 3

[0050] (1) Establish a spatial range R, where 0≤x≤20, 0≤y≤20, 0≤z≤20, and divide the space into grids, and divide the space with a unit size of 0.05, then each direction of R There are 400 elements, 401 nodes. Establish a spatial function f(x, y, z, a, t), and assign the initial value 0 to a and t of each node.

[0051] (2) Define the characteristic points of the porous structure at different positions in the three-dimensional space: A(0,0,0,2.55,0.1), B(20,20,0,2.55,0.1), C(0,0,20 ,2.25,0.2), D(20,20,20,2.25,0.2).

[0052] (3) According to the feature points defined in step (2), use the interpolation algorithm to obtain the function f value of each point in the middle, such as AC1(0,0,5,2.475,0.125), AC2(0,0,10, 2.4,0.15), AC3(0,0,15,2.325,0.175).

[0053] (4) Carry out the mathematical modeling of Schoen Gyroid porous structure according to f(x, y, z, a, t) at each point in space, b=5 in the formula (1), the value of t at each point can be used in the formula

[0054] f(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com