Pouch lithium ionic battery case and packaging method thereof

A lithium-ion battery, ion battery technology, applied in the direction of battery box/jacket, secondary battery, battery pack parts, etc. Excellent production rate, preventing the battery top seal from being too small, and saving shell materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

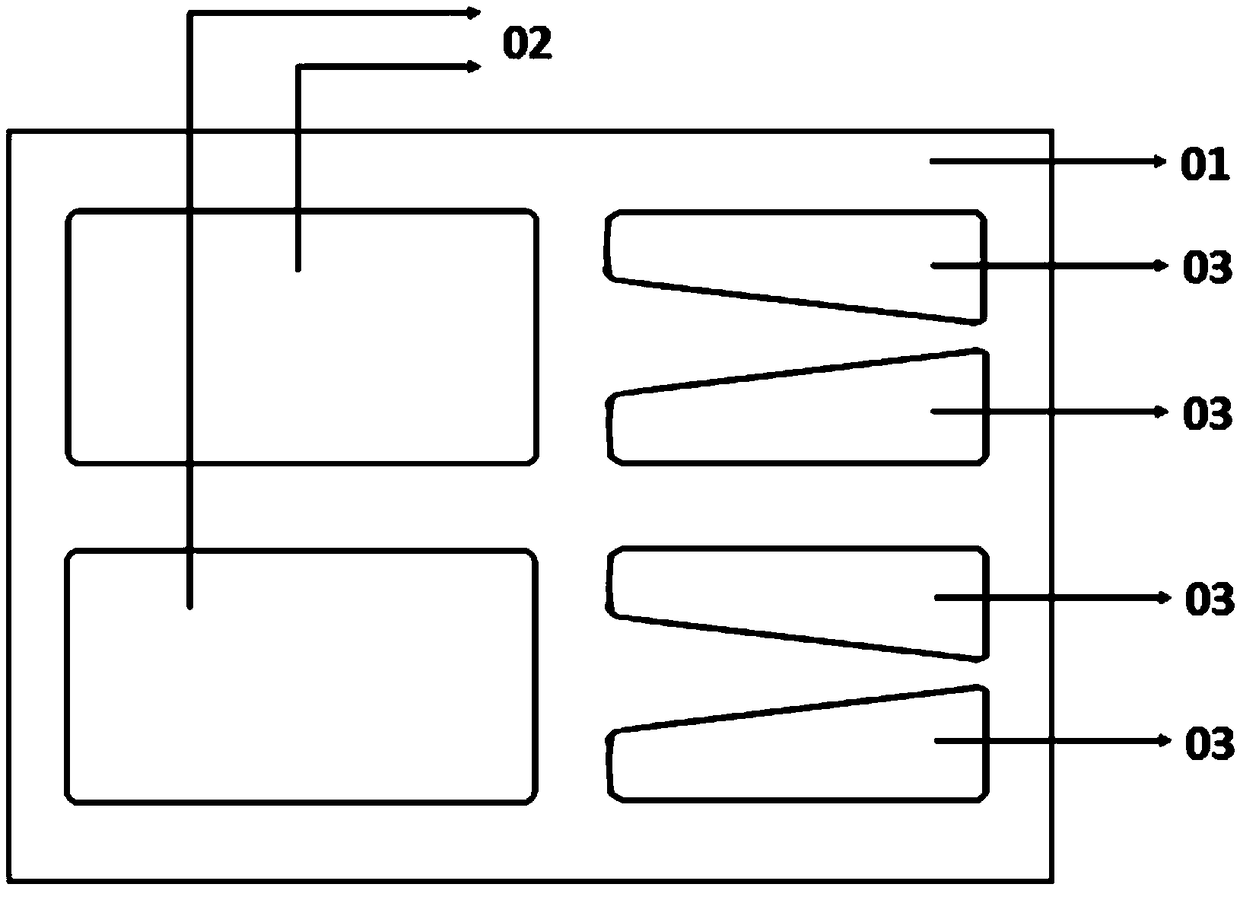

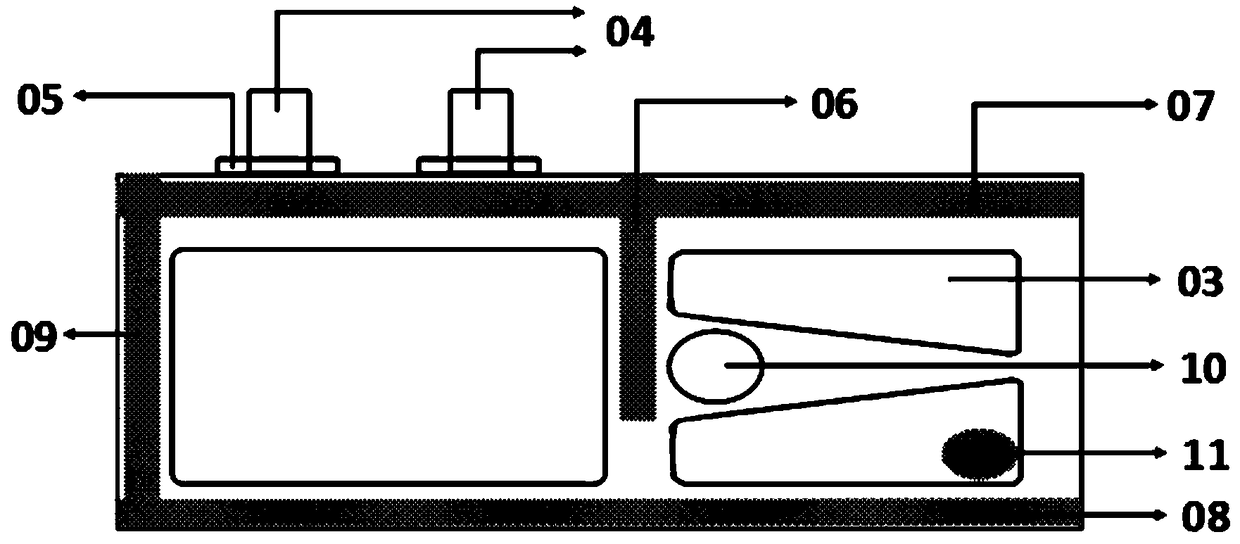

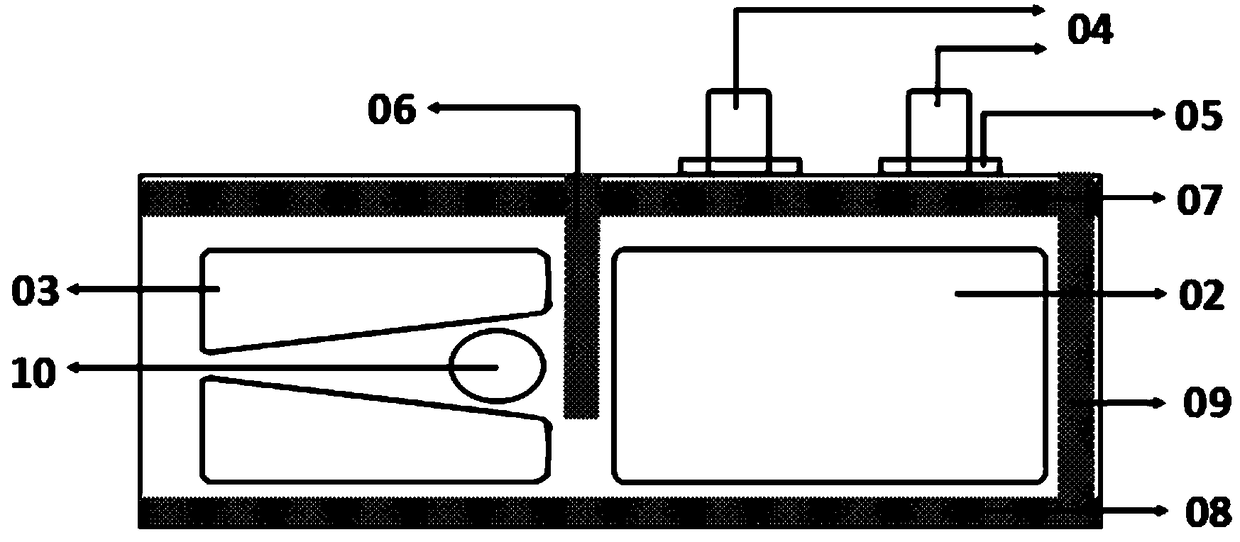

[0046]A casing for a soft-packed lithium-ion battery, comprising a main body, one side of the main body is provided with an outwardly protruding inner pit 02, or both sides of the main body are respectively provided with an outwardly protruding inner pit 02, and the two inner pits 02 Symmetrically arranged; one side of the main body is provided with an air bag that needs to be removed after exhaust packaging, and at least one small pit 03 protruding outward is provided on the air bag.

[0047] A plurality of small pits 03 are symmetrically arranged on both sides of the air bag, and the small pits 03 on different sides are arranged symmetrically with respect to the air bag. The cross-sectional shape of the small pit 03 parallel to the air bag is trapezoidal. The shorter one of the parallel sides is close to the main body, the right-angled side of the two non-parallel sides is close to the top or bottom of the cell, and the corners of the small pit 03 are rounded.

[0048] A cas...

Embodiment 2

[0067] Before step S0, the fabrication of bare cells is also included. The positive electrode sheet and the negative electrode sheet are prepared according to the current commercialized conventional process, and then prepared into bare cells together with the separator. The thickness of the bare cell is less than 2.2mm.

[0068] S0: Production of the battery casing: According to the thickness of the bare cell, the shell punching method of the aluminum-plastic film is a single pit, that is, only one inner pit 02 is punched. There are four right-angled trapezoidal small pits 03 on the upper punch of the air bag.

[0069] S1: Top sealing and side sealing: Put the bare cell into the inner pit 02, perform top sealing and side sealing according to certain packaging parameters, and the inner sealing area of the top sealing is 0.8mm.

[0070] S2: Corner pre-encapsulation: In order to prevent the corners connecting the air bag and the bottom of the main body from being damaged due t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com