Base assembly and food processor

A food processor and component technology, which is applied to electric components, electromechanical devices, electrical components, etc., can solve the problems of poor heat dissipation effect and complex heat dissipation structure, and achieve the effect of good heat dissipation effect, simplified structure, and improved satisfaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

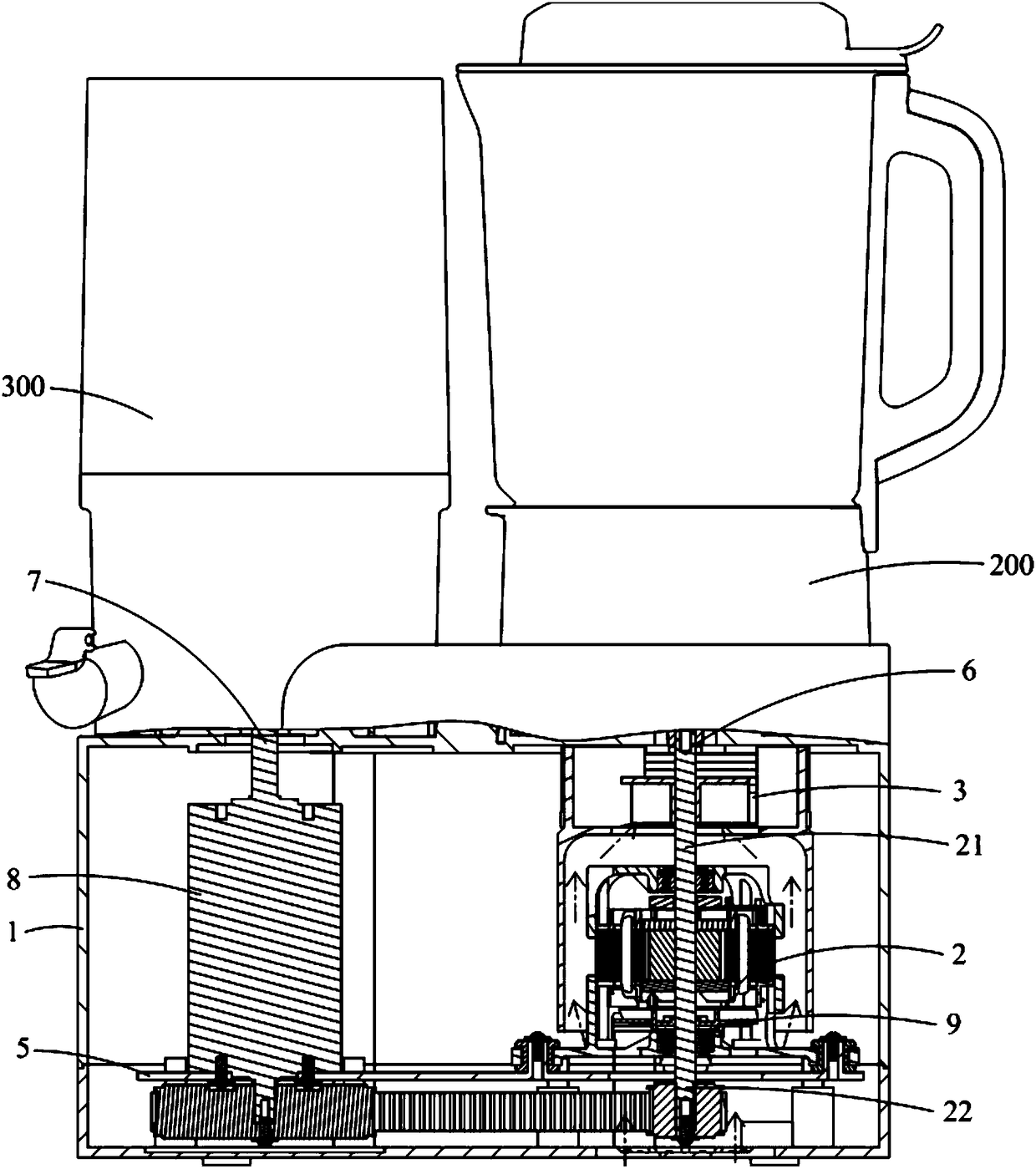

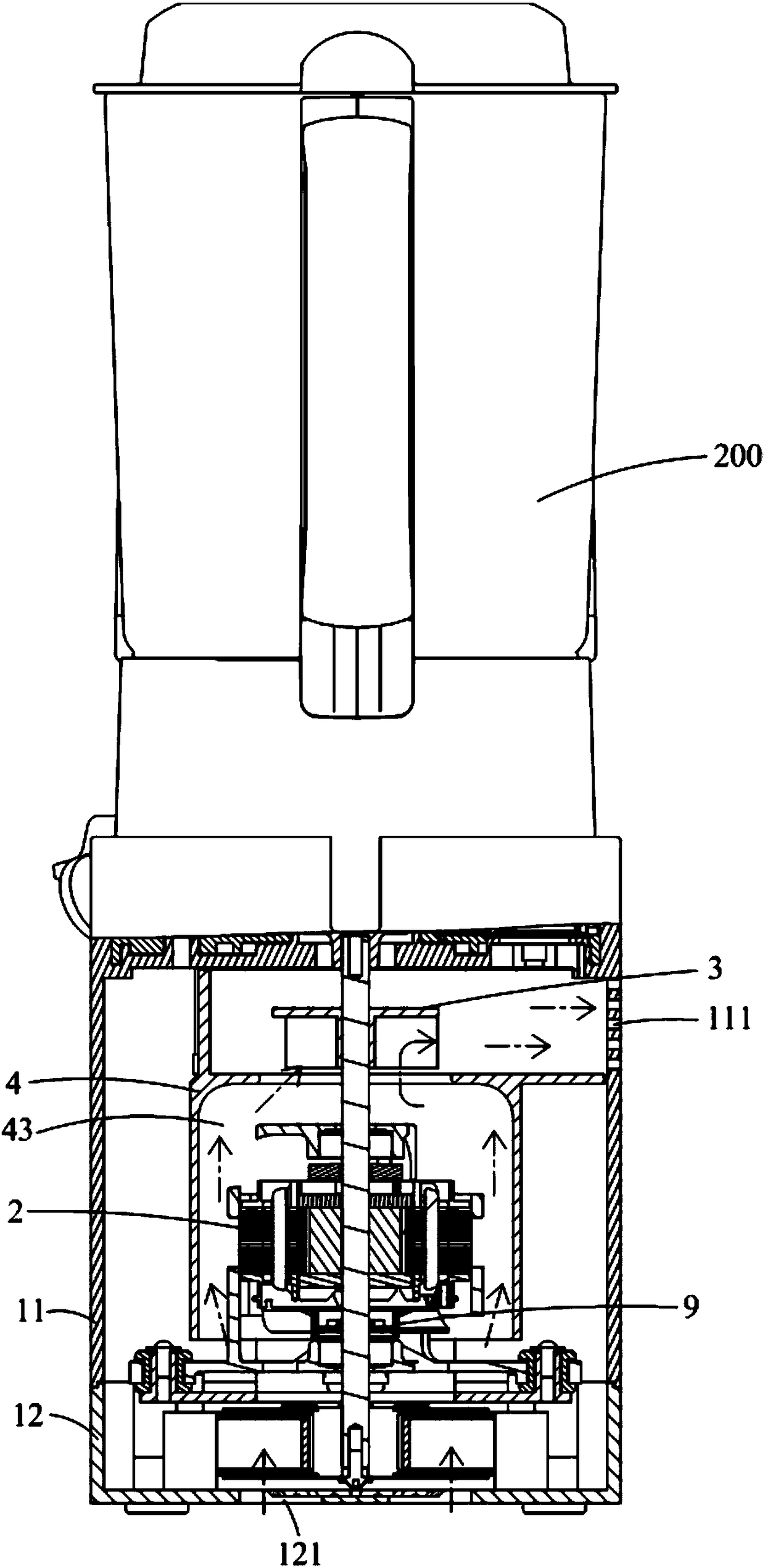

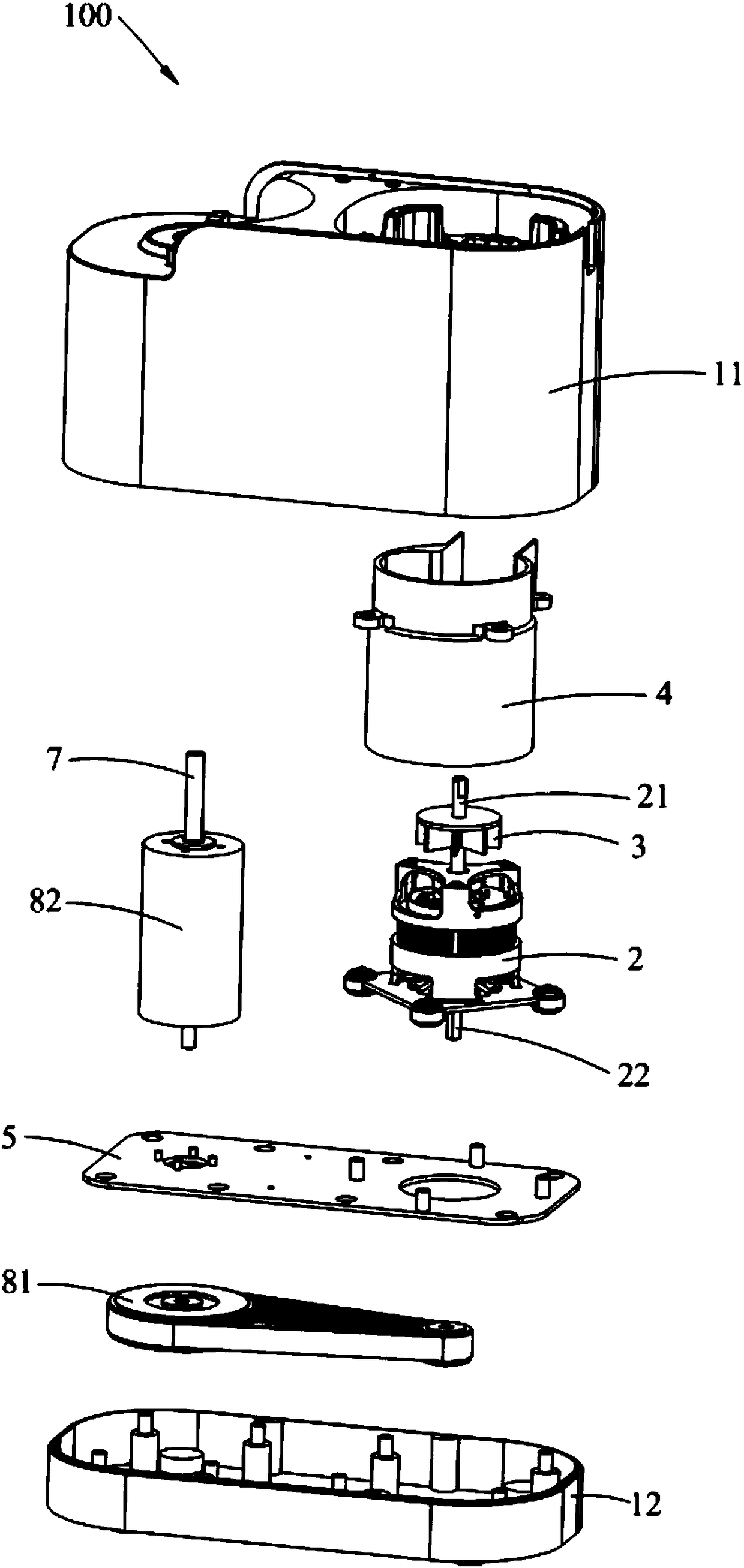

[0036] Such as Figure 1-4 As shown, the base assembly 100 provided by Embodiment 1 of the present invention is used for a food processor, and includes a base housing 1, a motor 2 disposed inside the base housing 1, and a control panel disposed on the outer side of the base housing 1, The bottom of the machine base shell 1 is provided with a first vent 121, and the side is provided with a second vent 111. The motor 2 has an upper output shaft 21 and a lower output shaft 22 which are reversely arranged in the vertical direction, and the upper output shaft 21 and The lower output shaft 22 is respectively assembled with a first cooling fan 3 and a second cooling fan 9 for accelerating air flow between the first ventilation opening 121 and the second ventilation opening 111 .

[0037]Specifically, the motor 2 is installed in the machine base housing 1 in such a way that its central axis is placed vertically, and the upper output shaft 21 is located above the lower output shaft 22 ...

Embodiment 2

[0061] The main difference between the base assembly 100 and the food processor provided in this embodiment and the first embodiment is that the setting of the first heat dissipation fan 3 and the flow direction of the air are different, which are specifically reflected in: Figure 1-4 As shown, in Embodiment 1, the first cooling fan 3 is a centrifugal fan, the second cooling fan 9 is an axial flow fan, the first vent 121 is an air inlet, the second vent 111 is an air outlet, and the first cooling fan 3 When the second radiating fan 3 is in operation, the cold air from the outside is sucked into the base shell 1 from the first vent 121 at the bottom of the base shell 1, and the cold air from the outside enters the base shell 1 and flows from bottom to top. And flow to the first heat dissipation fan 3 after heat exchange by the motor 2, the first heat dissipation fan 3 throws the hot air flowing to it through the motor 2 to the second vent 111 on the side of the base shell 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com