Anode-imitating craft injection-molded part applicable to mobile phone back cover and processing technique thereof

A technology for mobile phone back cover and injection molding, which is used in household components, applications, decorative arts, etc., can solve problems such as excessive thickness and deformation, and achieve the effects of strong plasticity, beautiful appearance and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

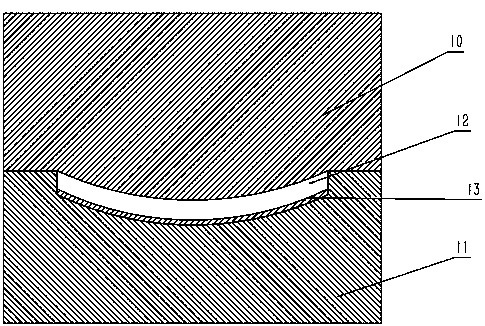

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it should not be understood that the scope of the above-mentioned theme of the present invention is limited to the above-mentioned embodiments.

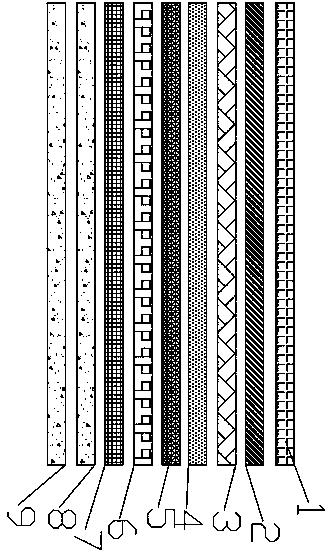

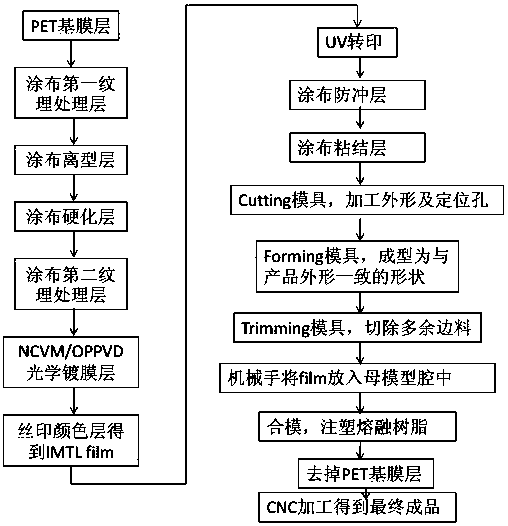

[0030] Such as figure 1 As shown, an injection molded part with imitation anode technology suitable for the back cover of a mobile phone includes a resin injection molded part shell and a PET base film layer 1 and a color layer 7 arranged between the injection molded part shell and the PET base film layer 1, the color An NCVM / OPPVD optical coating layer 6 is provided between the layer 7 and the PET base film layer 1, and the color layer 7 is connected to the housing of the resin injection molded part through an adhesive layer 9 and an anti-shock layer 8, and the NCVM / OPPVD optical coating layer 6 is provided with There is a second texture treatment layer 5, a hardening layer 4 is provided on the top of the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com